Robot Safety Module Datasheet

Contents

Overview

The Robot Safety Module is the interface between Vention’s MachineMotion 2 controller & Vention’s partner robots’ safety interfaces. The Robot Safety Module manages the safety fault events that happen on the machine to safely stop both the MachineMotion 2 controller and the robot. With the Robot Safety Module connected in Vention’s safety chain, a safety event from the robot will stop the MachineMotion 2 controller and a safety event from Vention’s safety chain will also stop the robot. The Robot Safety Module also serves as an Ethernet switch between Vention’s Pendant, MachineMotion 2 controller and the robot.

Features

- Configuration Free, Plug & Play

- Compatible with MachineMotion 2

- Daisy-chainable

- Compatible with multiple Cobot brands

- On-board status LED

- Internal 3 port Ethernet switch

Technical Specifications

General Specifications

| Part Number | CE-SA-009-0000 |

| Weight | 1 kg |

| Dimensions | 66 x 127 x 172 mm |

| Material |

|

| Operating Temperature | 0 to 40°C |

| Certifications | CE |

| Included in the Box |

|

Physical Interface

Electrical Specifications

| Nominal Input Voltage | 24 VDC |

| Input Voltage Range | 19.2 - 26.4 VDC |

| Operating Power Consumption | 4.8 W |

| FROM ROBOT Connector Input Type | Redundant 24V (4 contacts) |

| TO ROBOT Connector Output Type |

|

| Short Circuit Protection | Internal E-FUSE IC |

| Maximum Current Allowed | 2 A |

| Post-short Current | 250 mA |

| Release Delay at 24V | < 40 ms |

| Reset Total Delay | 7 seconds |

| Ethernet Switch | 3 ports 10/100MB |

Pinout

FROM ROBOT port

Connector: M12, female, 4-pin, A-Keyed

| Pin | Description |

|---|---|

| Pin 1 | Robot Safety Output 0V Contact 1 |

| Pin 2 | Robot Safety Output 24V Contact 1 |

| Pin 3 | Robot Safety Output 0V Contact 2 |

| Pin 4 | Robot Safety Output 24V Contact 2 |

TO ROBOT port

Connector: M12, male, 12-pin, A-Keyed

| Pin | Description |

|---|---|

| Pin 1 | NC |

| Pin 2 | NC |

| Pin 3 | Robot Safety Input Channel 1 Contact 1 |

| Pin 4 | Robot Safety Input Channel 1 Contact 2 |

| Pin 5 | Robot Safety Input Channel 2 Contact 1 |

| Pin 6 | Robot Safety Input Channel 2 Contact 2 |

| Pin 7 | Robot Input Reset Contact 1 |

| Pin 8 | Robot Input Reset Contact |

| Pin 9 | Robot Ethernet TX+ |

| Pin 10 | Robot Ethernet TX- |

| Pin 11 | Robot Ethernet RX+ |

| Pin 12 | Robot Ethernet RX- |

SAFETY IN port

Connector: M12, female, 12-pin, A-Keyed

| Pin | Description |

|---|---|

| Pin 1 | 24V |

| Pin 2 | 0V |

| Pin 3 | MachineMotion Safety Channel 1 Contact 1 |

| Pin 4 | MachineMotion Safety Channel 1 Contact 2 |

| Pin 5 | MachineMotion Safety Channel 2 Contact 1 |

| Pin 6 | MachineMotion Safety Channel 2 Contact 2 |

| Pin 7 | Input Reset Contact 1 |

| Pin 8 | Input Reset Contact 2 |

| Pin 9 | Pendant Ethernet TX+ |

| Pin 10 | Pendant Ethernet TX- |

| Pin 11 | Pendant Ethernet RX+ |

| Pin 12 | Pendant Ethernet RX- |

SAFETY OUT port

Connector: M12, male, 12-pin, A-Keyed

| Pin | Description |

|---|---|

| Pin 1 | 24V |

| Pin 2 | 0V |

| Pin 3 | MachineMotion Safety Channel 1 Contact 1 |

| Pin 4 | MachineMotion Safety Channel 1 Contact 2 |

| Pin 5 | MachineMotion Safety Channel 2 Contact 1 |

| Pin 6 | MachineMotion Safety Channel 2 Contact 1 |

| Pin 7 | Output Reset Contact 1 |

| Pin 8 | Output Reset Contact 2 |

| Pin 9 | MachineMotion Ethernet TX+ |

| Pin 10 | MachineMotion Ethernet TX- |

| Pin 11 | MachineMotion Ethernet RX+ |

| Pin 12 | MachineMotion Ethernet RX- |

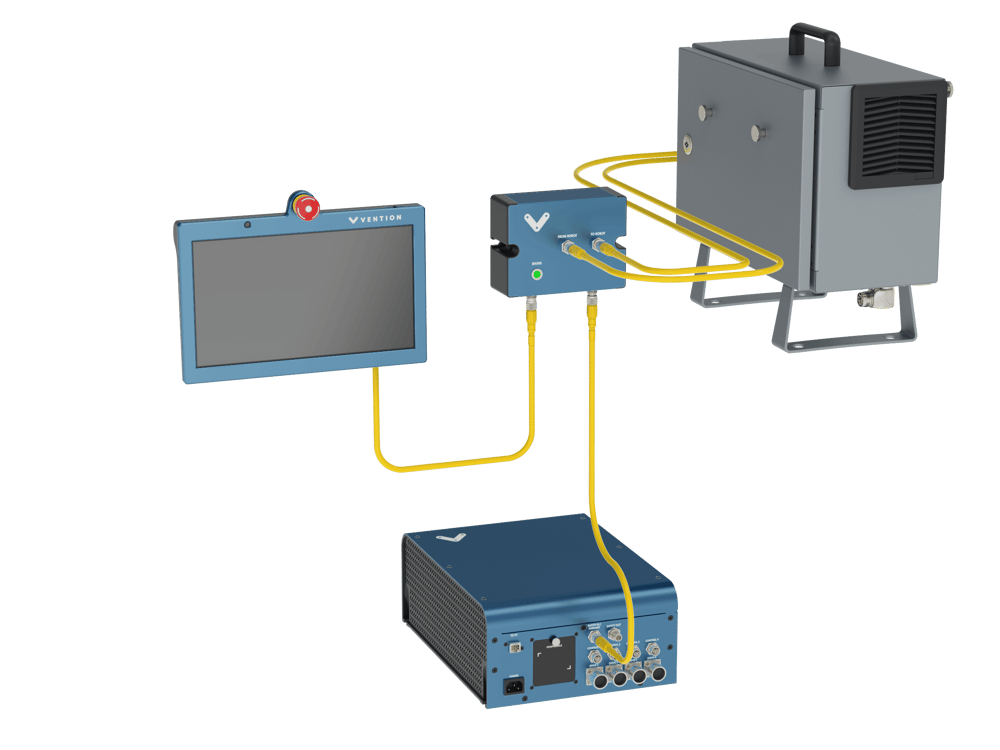

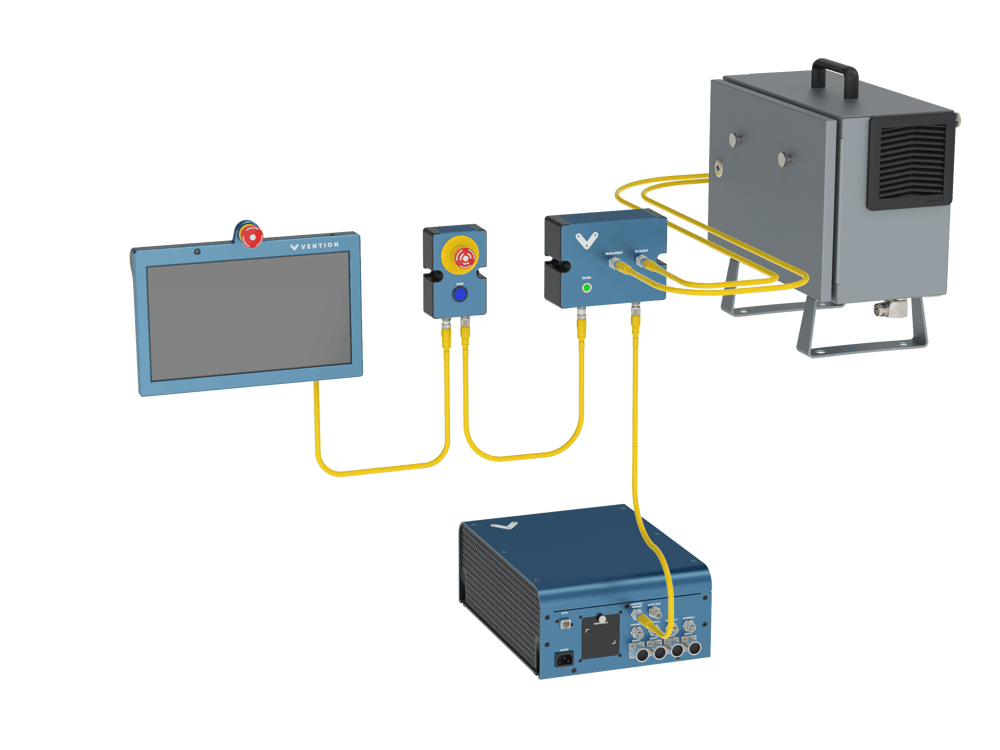

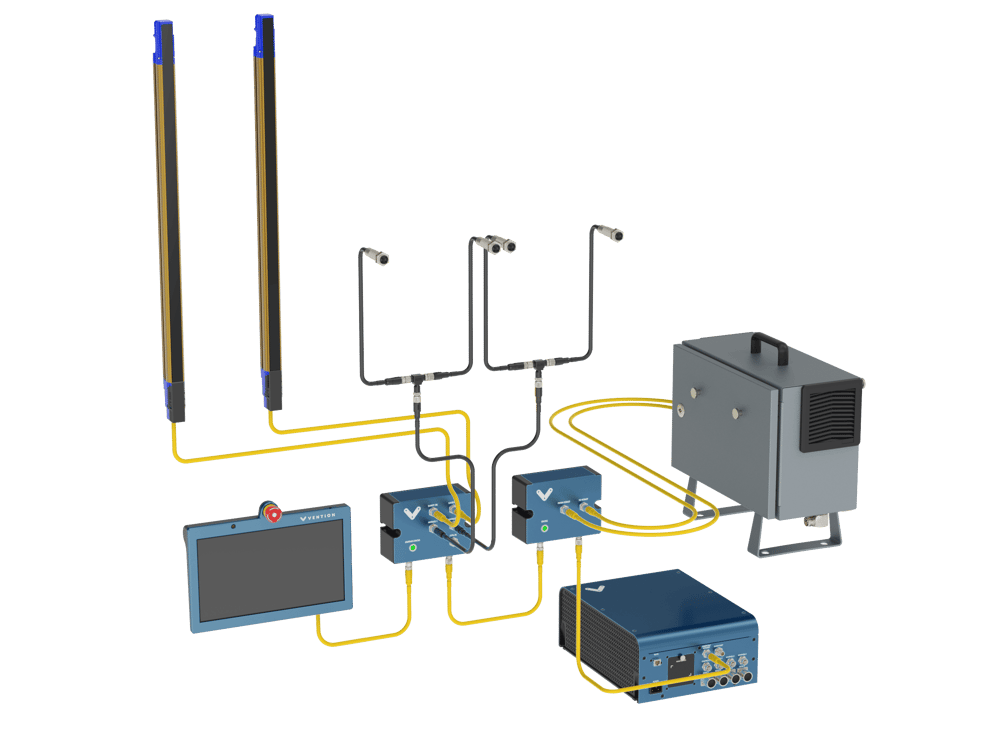

Applications

The Robot Safety Module can link the safety interfaces of Cobots with MachineMotion 2. The following diagrams show the typical use-cases of the module:

Use Case Examples

Safety Data

The Robot Safety Module is used to propagate safety signals between :

- The SAFETY IN port to the TO ROBOT port

- The FROM ROBOT port the SAFETY OUT port; and

- The SAFETY IN port to the SAFETY OUT port.

For each of these functions performed by the Robot Safety Module, safety data can be found in the following table:

| Function | PL | Cat. | MTTFd | DCavg |

|---|---|---|---|---|

| From Robot to Safety OUT | e | 3 | 128.3 | 98.72% |

| From Safety IN to To Robot | e | 3 | 65.8 | 98.90% |

| From Safety IN to Safety OUT | e | 3 | 126.1 | 98.81% |

The above information have been calculated based on the following operation conditions:

| Data | Value | Unit |

|---|---|---|

| dop | 365 | days/years |

| hop | 24 | hours/days |

| tcycle | 8640 | s/cycle |