PICK AND PLACE ROBOT ARMS

Automated pick and place systems

Vention's Pick and Place robot arm solution allow you to introduce automation to your production line quickly and easily. Using our modular parts library, design a robot pick and place robot cell to meet your unique specifications. After your have a design, you can then program it directly from your web browser using our intuitive, code-free programming environment.

WHAT DO PICK AND PLACE ROBOTS SOLVE?

Eliminate errors & risks with automated pick and place

Robot-agnostic

Use with your preferred robot brand of FANUC, Universal Robots, Epson, Doosan, and more for pick and place automation.

Full ecosystem

A modular robot pick and place solution with a wide variety of compatible robot bases, end-of-arm-tools, safety enclosures, conveyors, and more.

Quick lead time

Have your pick and place robot cell ship within one to two weeks to accelerate your automation roadmap.

Easy to program

Program and deploy pick and place robot solutions entirely code-free with an intuitive user interface.

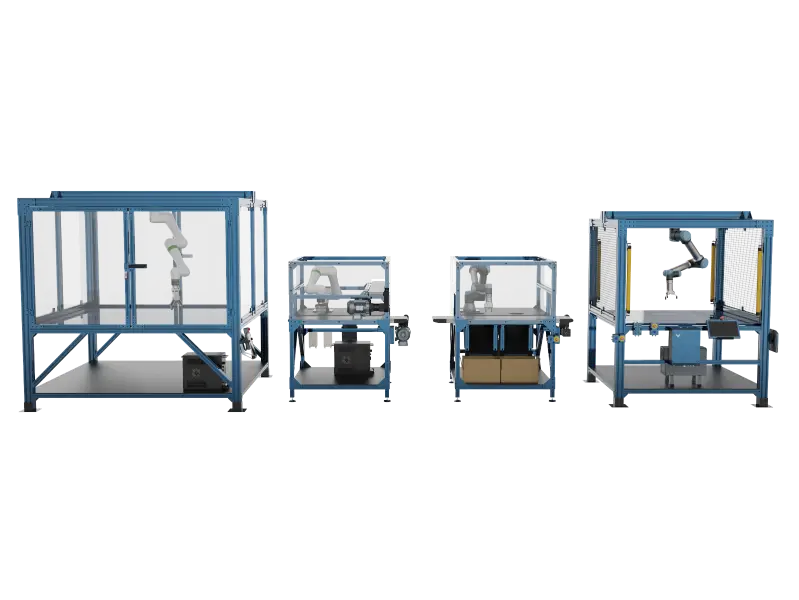

PICK AND PLACE ROBOT CONFIGURATIONS

Configure your pick and place robot solution

Fenceless cell

Best for:

Leveraging the collaborative function of pick and place cobots so the operator can work closely within the cell.

Enclosed cell

Best for:

Non-collaborative situations/environments where sharp objects move at high speeds during the process.

Standalone robot

Best for:

Mobile pick and place operations that require a movable and simple robot pedestal design. Select the gripper, safety modules, and peripheral equipment according to your specific needs.

Templates

Select an automated pick and place template to get started

Find fully customizable templates by inputting your specifications.

CALCULATE ROI

Earn strong ROI with Vention Pick and Place Robots

Your process

Your design

Your savings

CUSTOMER STORY

MMTC Automation Education

Challenge

Educational organizations, such as the Michigan Manufacturing Technology Center (MMTC), typically have to narrow their focus of education to aid the acquisition of their own training technology. To educate their clients on a broad range of automation applications, MMTC turned to Vention to create a modular pick & place application.

Solution

MMTC commissioned a pick and place machine that encompassed a broad range of use cases and differing levels of automation. This machine, which was designed and deployed within two weeks, helps demonstrate to clients the value and versatility of manufacturing automation. MMTC now transports this single machine statewide to more effectively educate and train users.

Vention Products

Educational Resources

Pick and place resources to get you up and running

Explore our technical documents, video tutorials, and deployment guides for indepth information about Vention products and tools.

Request a Quote

Expect a call within 24 hours. Yes, we're quick.