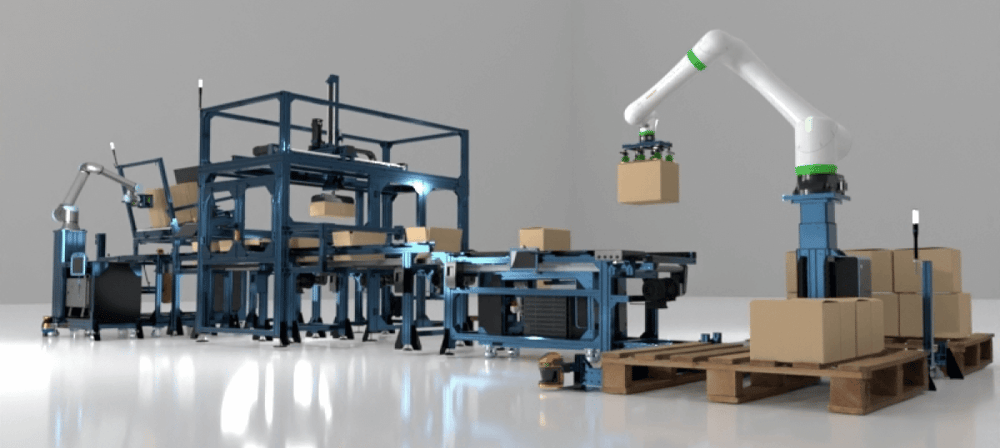

End-of-line solutions to eliminate labor shortages

End-of-line packaging is an essential part of any manufacturing line. Packaging products correctly and consistently is critical as one of the last steps in your operation. Traditionally, labor shortages highly affect end-of-line packaging, which consists of manual, repetitive, and labor-intensive tasks. Introducing automation to complete some or all of these tasks eliminates labor shortages while increasing productivity, reducing injuries, improving quality, and producing fast ROI.

End-of-line packaging solutions for your manufacturing floor

To improve your assembly line and eliminate labor shortages, we suggest introducing automation for the manual tasks of erecting and taping, packing, and palletizing. We offer a range of custom and standardized solutions to meet the needs of your manufacturing floor.

Custom solutions are ideal for those with unique specifications and a desire for a solution that can grow and evolve alongside the business. When designing applications through the Manufacturing Automation Platform, our library of 1,000+ modular components enables easy changes as operations scale, ensuring that both your current and future packaging needs are always met.

Standardized solutions are ideal for customers with more simple use cases that don’t require equipment modifications. These solutions are also ideal for manufacturers looking to begin automating in under two weeks.

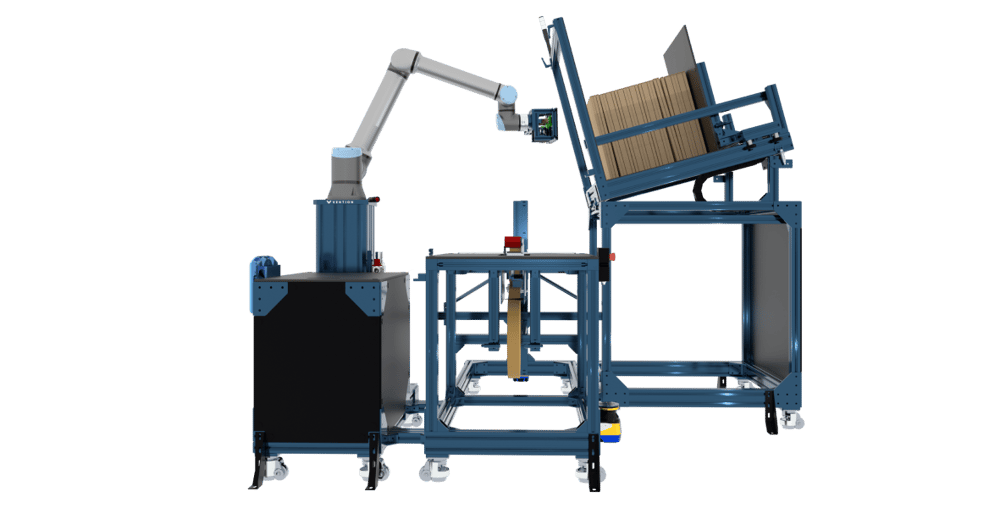

Box Erecting Robots

Vention’s Box Erecting solution helps remove additional labor demands from end-of-line production. This solution is adaptable to a wide range of box sizes and can be fully tailored to match your production needs and adapt to the layout of your manufacturing floor.

Featuring extra-large magazines, form enough boxes for two pallets without refilling. Compatible robot arms include Universal Robots, Doosan, and FANUC.

| Efficient Production | Customizable | Turnkey Solution | Quick Lead Time |

|---|---|---|---|

| Produce up to 7 boxes per minute with the option for extra large magazines to form boxes for up to 2 pallets without refilling. | Adaptable to a wide range of box sizes with multiple magazine options for running different SKUs simultaneously. | Out-of-the-box functionality with an intuitive interface allows you to create new SKUs within minutes. | Ships in 14 weeks giving you all the flexibility to accelerate your automation roadmap. |

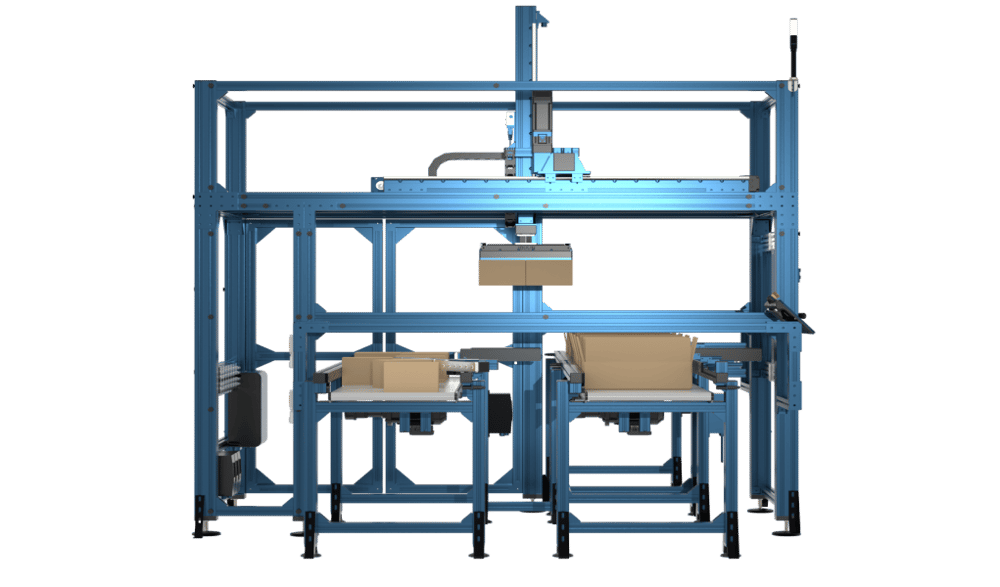

Case Packing Robots

Vention’s Case Packing solution is the perfect addition to your end-of-line production. The turn-key design seamlessly integrates with our other end-of-line applications, including cobot palletizers and box erectors. The intuitive interface can create new product patterns within boxes and trays in minutes, making it easy to adapt to your exact production needs.

| Quick Payback | Fast Deployment | Easy to Program | Powerful Support |

|---|---|---|---|

| See ROI in 9 months or less with all the flexibility to customize to your unique needs. | Deploy in under 3 days allowing you to quickly address your automation needs. | Create new product patterns within boxes and trays in minutes with our intuitive operator interface. | Support up to 50kg payload, designed with the highest industry and safety standards. |

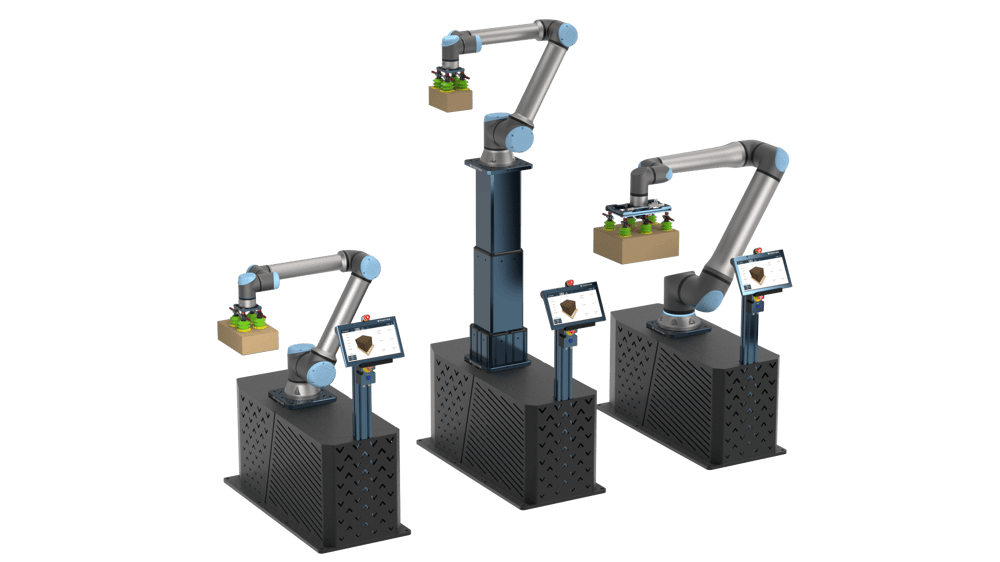

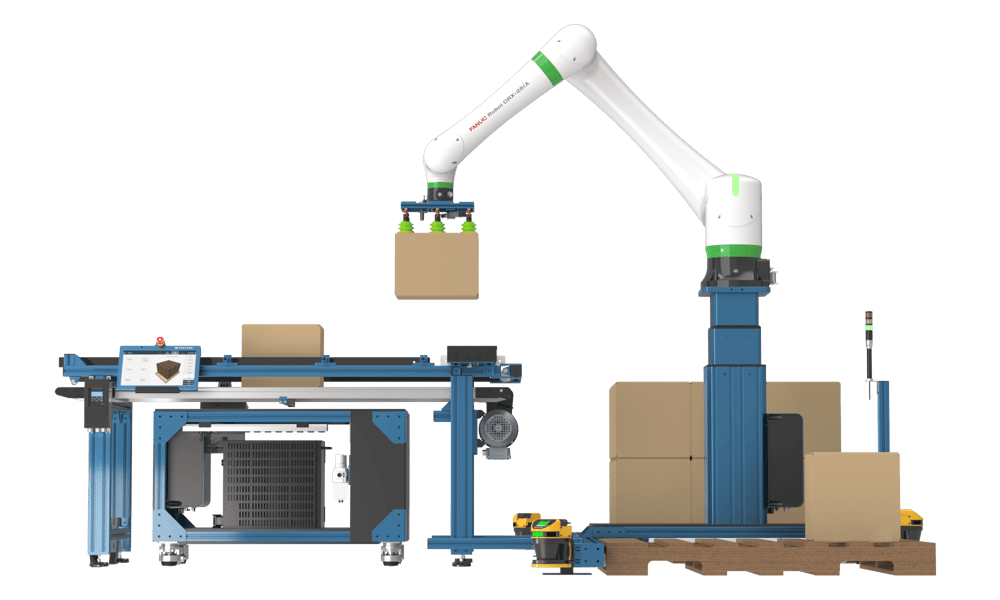

Palletizing Robots

Vention offers both custom and standardized palletizing solutions to palletize a wide variety of products.

The need for quick deployment and effortless implementation gave rise to Vention’s newest cobot palletizer application, the Rapid Deployment Robot Palletizer. The standardized design is our most compact, scalable, and cost-effective palletizer yet, and with solutions beginning under 100k USD, you can expect a return on investment in as little as six months. Discover this next-generation solution.

| Fast Delivery | Quick Payback | Simple Pattern Adjustments | Small Footprint |

|---|---|---|---|

| Receive your palletizer in as little as 5 days and commission it in even less time thanks to our de-risked designs. | See ROI as quick as in 6 months, allowing you to accelerate your automation roadmap. | Create and adjust patterns manually or use the smart auto pattern generation through MachineApp without having to stop production. | Our palletizers are optimized to be as small as possible and fit on a standard pallet. |

For a fully tailored palletizer, try one of our modular palletizers, available in medium and heavy payload configurations. Choose from your preferred robot brand, base, pallet type, and infeed conveyor to create a solution to meet your unique needs. Compatible robot arms include Universal Robots, Doosan, and FANUC.

| Quick Payback | Fast Deployment | Simple Pattern Adjustments | Customizable |

|---|---|---|---|

| See ROI in 9 months or less allowing you to accelerate your automation roadmap. | Deploy in under 3 days with either turn-key or self-deployment. | Create and adjust patterns manually or use the smart auto pattern generation through MachineApp without having to stop production. | Support between 10kg to 30kg payload, with medium and heavy payload configurations customizable to your unique needs. |

No matter which palletizer you choose, each solution from Vention runs on MachineApps, our intuitive, easy-to-use software solution for configuring, programming, and operating the palletizer.

Try MachineApps for free today.

Talk to our experts about Industrial Robots for your plant

These three applications, used together or separately, can drastically improve your production process. Begin to see a return on your investment within the year while removing the effects of labor shortages on your end-of-line packaging operation.

Chat with our experts today to learn how to introduce automation to your end-of-line.