Choosing Panel Materials and Panel Strips

Overview

Selecting the proper panel material for your application can be a daunting task, but it is crucial in determining the success or failure of the application.

When selecting panel materials, one has to choose between materials with many different properties, ranging from mechanical strength to heat, chemical or even electrical resistance. Therefore, being able to select the appropriate material for your application requires careful consideration of the application conditions and design constraints.

Know Your Application

The most important factors to know are:

- Mechanical strength: How strong must the material be to withstand loads, stress and impact?

- Temperature range: What are the minimum and maximum temperatures the material must withstand for prolonged or short periods of time?

- Chemical strength: How inert must the material be when in contact with any potent chemical substances such as solvents, highly acidic or basic solutions, etc.?

- Appearance: What color, surface roughness and how translucent or opaque should the material be?

- Machinability: How should the material behave in machining operations and what is the required dimensional stability?

It is also important to consider specialized application constraints, which may require taking into account more exotic factors such as static electricity buildup, assembly strength/weight ratio, or load and friction bearing properties.

Get help from a specialist through Vention’s live chat or by emailing support@vention.cc.

Select Your Material

The following table includes Vention’s available range of panel materials that can be added directly to your 3D Vention design using the automatic panel creation feature and, unless otherwise stated, can be cut to custom dimensions.

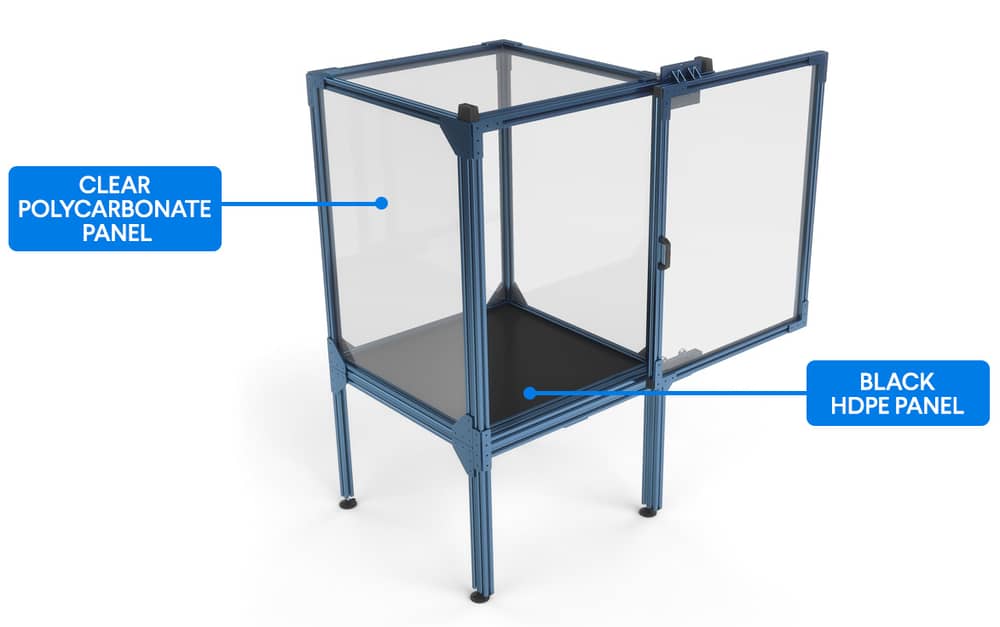

Plastic Panels

| Material | HDPE |

Polycarbonate |

Acrylic |

Phenolic C |

UHMW |

|---|---|---|---|---|---|

| Description | HDPE is an opaque, impact resistant and durable material with good chemical stability and an industrial finish. | Polycarbonate is a completely translucent and clear, impact resistant, shatter-proof material. It comes in a protective layer with a smooth, aesthetic surface. | Easy to machine, lightweight plastic. Available in opaque white or black aesthetic finish. | Opaque, amber-colored panel, easy to machine and offering excellent heat and electrical resistance. | UHMW is an impact resistant and durable material with good chemical stability and low coefficient of friction. |

| Common Application | As a base material for benches, tabletops, shelves, dividers and enclosures or sliding surfaces. Suitable for sanitary and food applications, as well as for general protection for resting parts. | Used in industrial applications requiring more durability than acrylic, such as safety enclosures, fencing, space dividers and other applications where transparency is required. | Used in enclosures and dividers for light ingress protection. Can also be used as a base material for shelves or other decorative constructions. | For tabletops and enclosures with high temperature and electrical insulation requirements. | Benches, tabletops, shelves, dividers and enclosures or sliding surfaces. Suitable for sanitary and food applications and in electronics workstations (anti-static panels). |

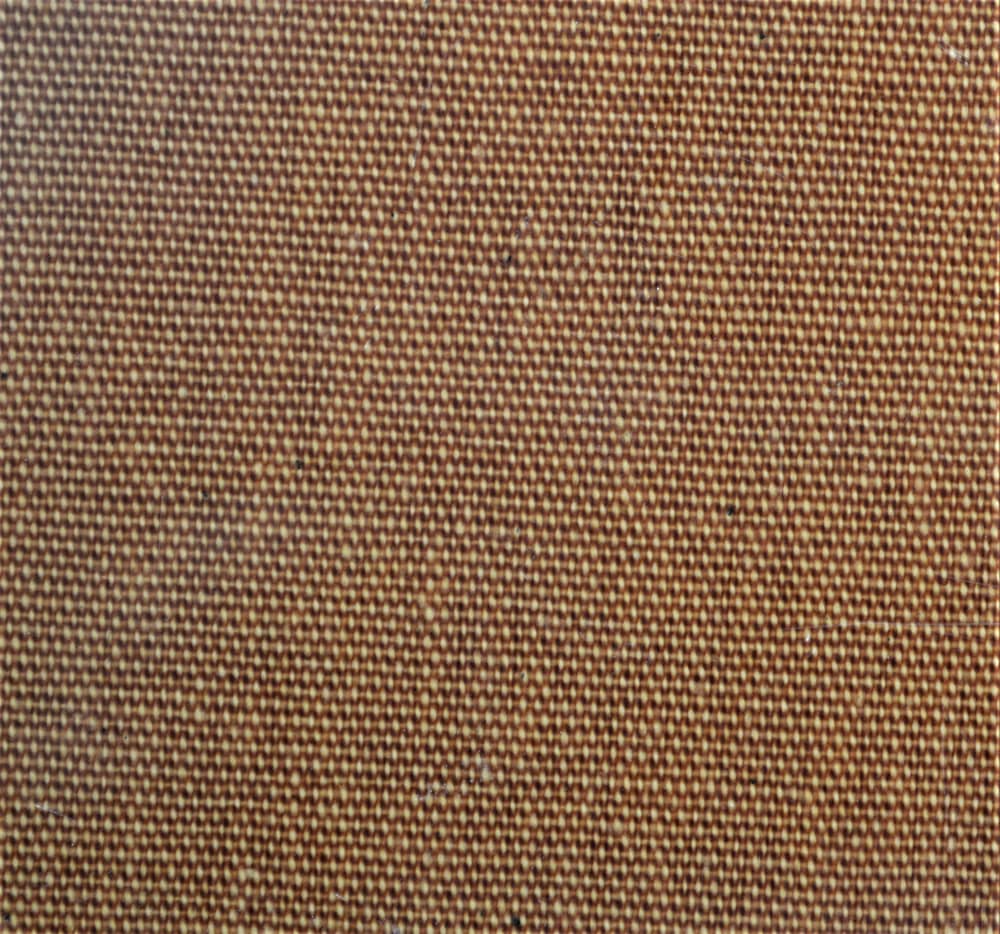

| Finish | White Black  Poly Eco  |

Clear |

White Black  Frosted  |

Phenolic C |

Black |

Metal Panels

| Material | Thermoplastic-coated wire mesh |

Aluminum |

Stainless Steel |

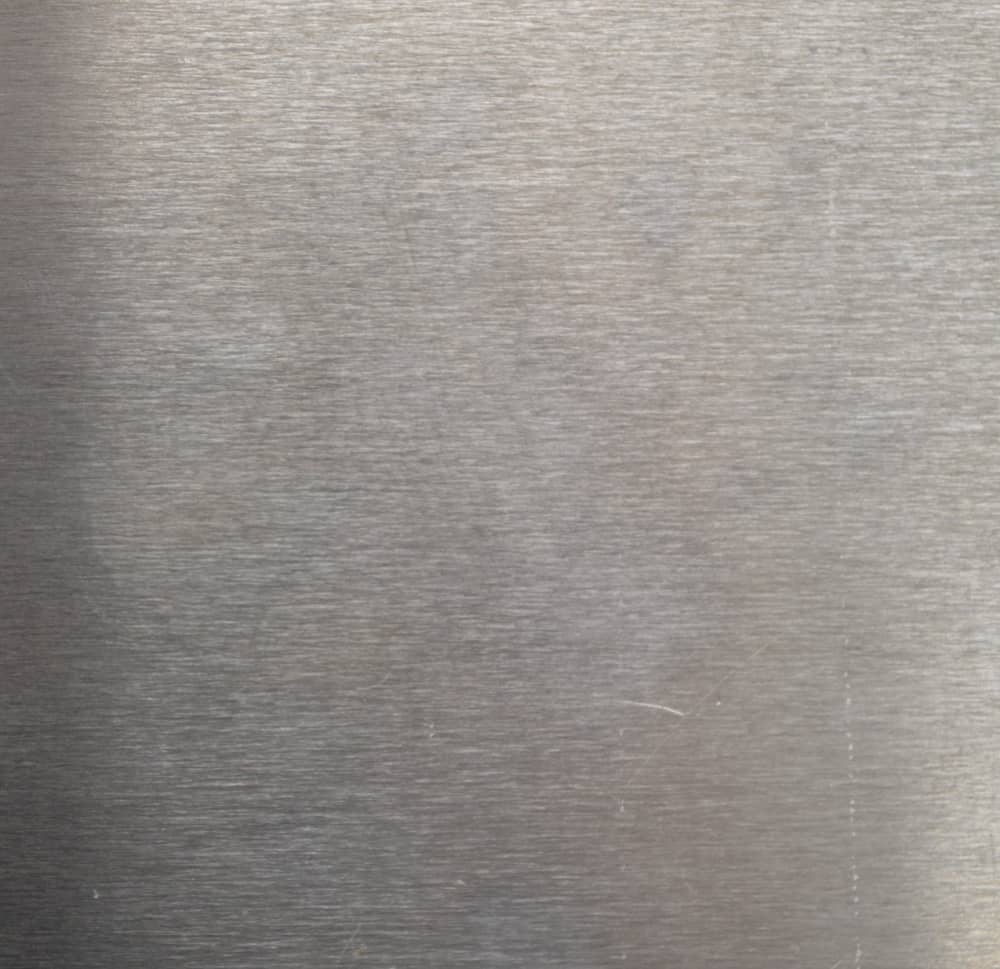

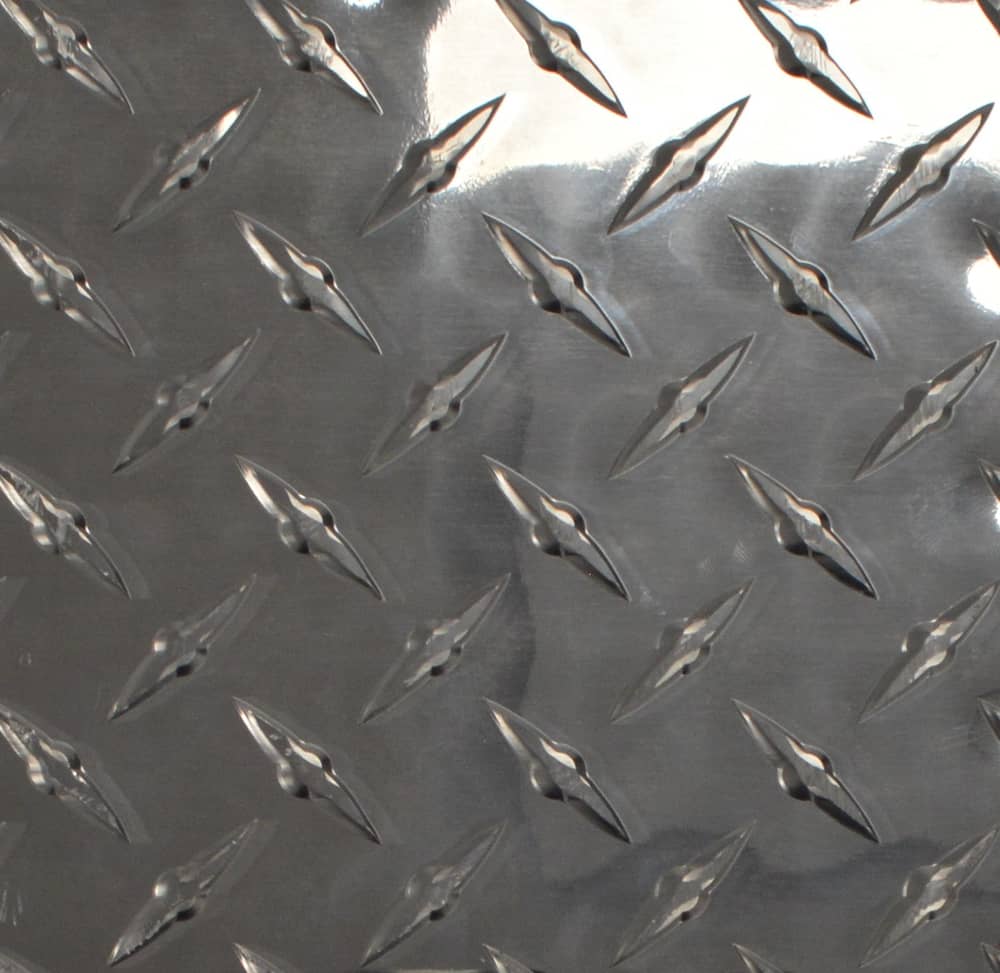

| Description | 5mm thick thermoplastic-coated wire mesh, with mesh of 25mm x 25mm squares. | Available in mill finish, brushed, or checkered, our aluminum panels are a strong, corrosion resistant, and aesthetically pleasing option. | Available in brushed (#4) finish, our 304 stainless steel panels are a strong, corrosion resistant, and aesthetically pleasing option for heavy duty applications. |

| Common Application | Safety fencing for medium-duty applications. Thermoplastic coatings prevents chipping and corrosion. | The mill and brushed finishes can be used as strong base panels, tabletops, enclosures, and dividers for heavy duty applications. The brushed finish should be used when aesthetics are key. Note that panels are brushed on one side only. The checkered finish, on the other hand, is a perfect option for flooring to prevent slippage. | Due to its very high strength and corrosion resistance, our stainless-steel panels offer our users the ability to use them in all sorts of environments and for all sorts of applications such as for base panels, table tops, enclosures, and dividers. Note that panels are brushed on one side only. |

| Finish | Plastic coated mesh |

Mill - 5052-H32 Brushed - 5052-H32  Diamond Plated - 3003-H22  |

Brushed #4 - 304 |

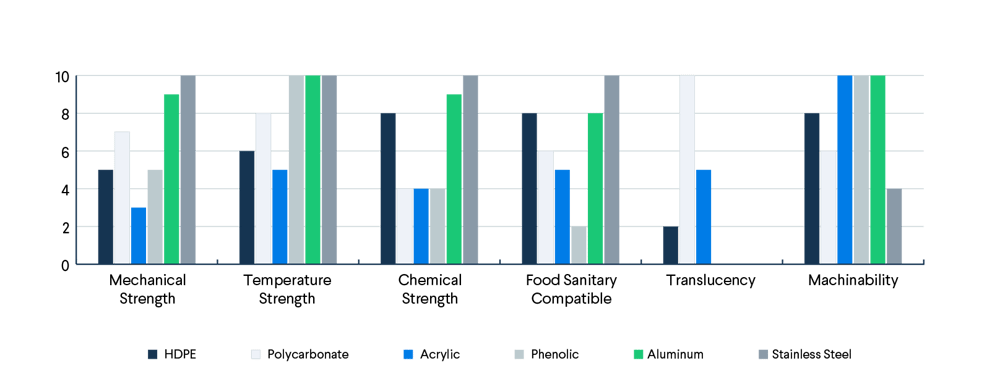

The graph below provides information on available solid panels with respect to their performance on a scale of 1 (poor) to 10 (excellent), for the primary material properties.

Panel Strips

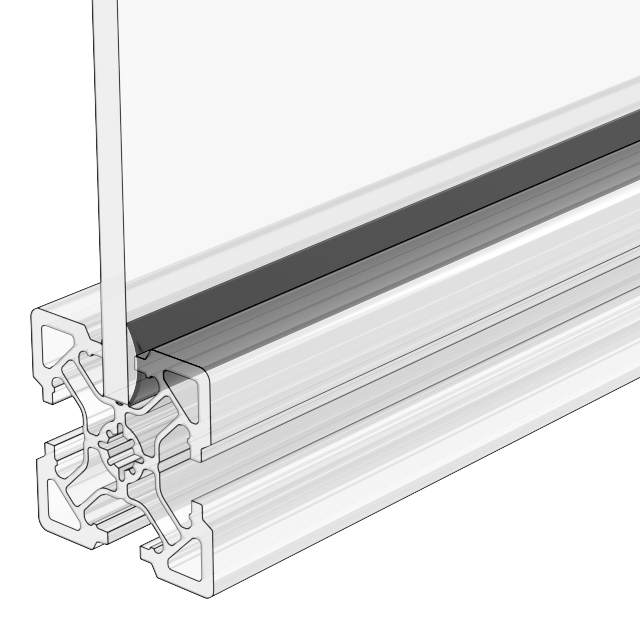

Panel strips are employed to secure panels firmly within the T-slots of extrusions. These strips are used to prevent panel rattling, create a seal at the junction between the panel and extrusion, and guarantee a smooth transition between the panel and the extrusion for a visually pleasing appearance.

There are 2 panel strips (ST-PN-014-0003 and ST-PN-014-0004) on our platform and each one works with specific panels. The following table shows the compatibility between the panels and the panel strips.

| Panels | Panel strip for 5.6 mm (0.22 inches) panels ST-PN-014-0003 |

Panel strip for 6.35 mm (0.25 inches) panels ST-PN-014-0004 |

|---|---|---|

| Polycarbonate Panel, Clear 0.22’’ [5.6mm] ST-PN-004-0001__2 |

✅ | ❌ |

| Acrylic Panel, White 0.22’’ [5.6mm] ST-PN-008-0002__2 |

✅ | ❌ |

| Acrylic Panel, Black 0.22’’ [5.6mm] ST-PN-008-0003__2 |

✅ | ❌ |

| HDPE Panel, White 1/4’’ [6.35mm] ST-PN-001-0003__2 |

❌ | ✅ |

| HDPE Panel, Black 1/4’’ [6.35mm] ST-PN-001-0004__2 |

❌ | ✅ |

| Phenolic C Panel, 1/4’’ [6.35mm] ST-PN-009-0001__2 |

❌ | ✅ |

| Anti-Static UHMW Polyethylene Panel, Black 1/4” [6.35mm] ST-PN-021-0001 |

❌ | ✅ |

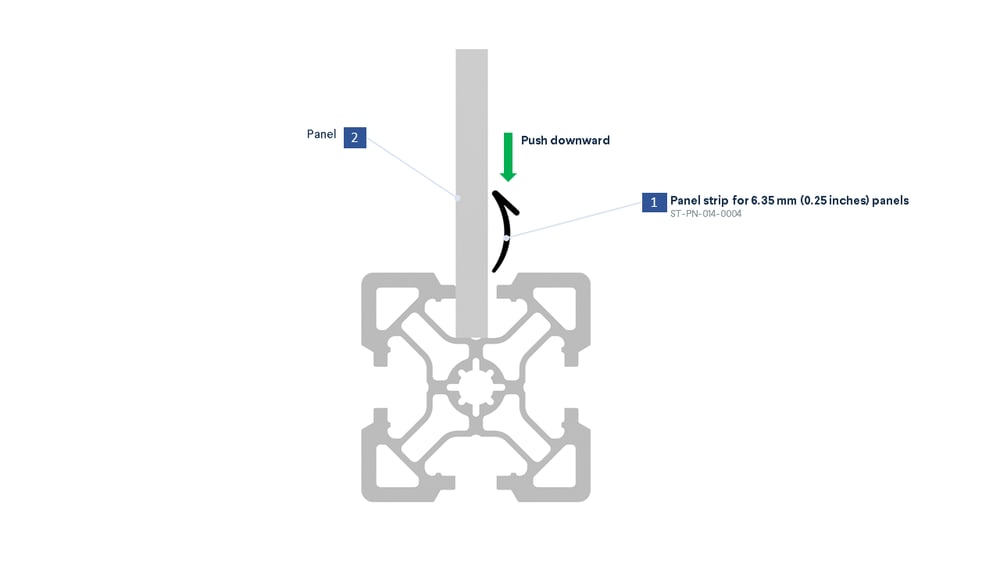

Installation

Panel strips are shipped in rolls and they need to be cut into required lengths. They need to be installed on one side of the panel. Cut the end at a 45-degree angle, starting from one side, use your fingers to push the panel strip between the panel and the extrusion. When pushed in, it squeezes and prevents the panel from rattling. The following picture shows the direction of the installation of the panel strips.