Cobot Pedestal

Overview

The cobot pedestal is the go to solution for static robot mounting. They are frequently used in robot tending stands, end of line palletizing applications and any other static robot stands.

The pedestal is composed of a 22.5mm top plate made from machined aluminum, the largest extrusion profile available as the main structural body, and a 22.5mm thick large format base plate with additional gusset bracing. This combination leads to an extremely rigid robot mounting solution and also keeps deployment simple and easy by reducing part count.

Applications

The cobot pedestal can be used for any application where a robot needs to be mounted on a fixed pedestal. Most applications are static but the cobot pedestal can also be mounted on a horizontal range extender to give an elevated mounting point if desired. The following sections provide examples of the typical use cases for the cobot pedestal.

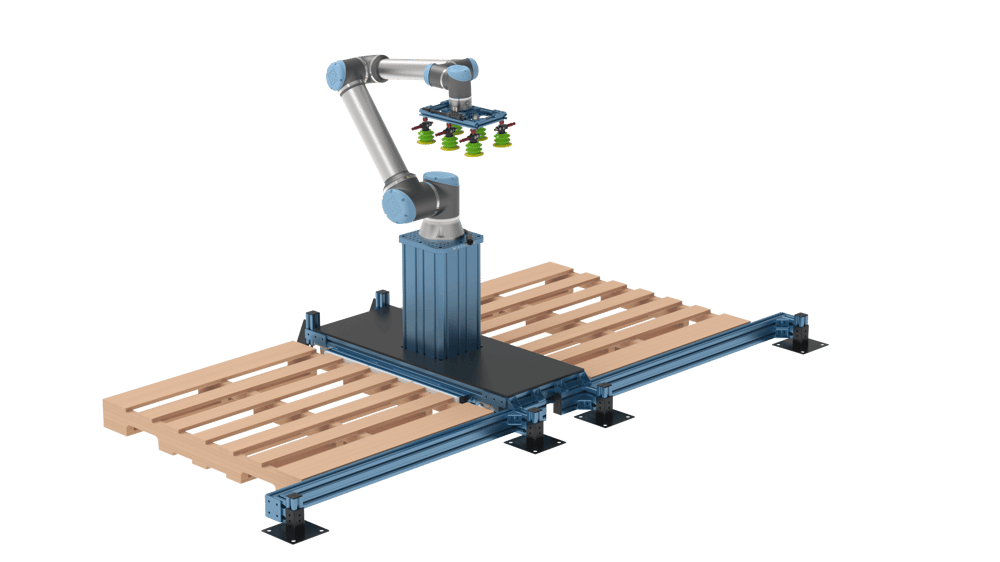

Cobot palletizers

The cobot pedestal is the perfect choice for adding some vertical reach to a cobot palletizing solution. This is the structure of choice for static mount cobot palletizers.

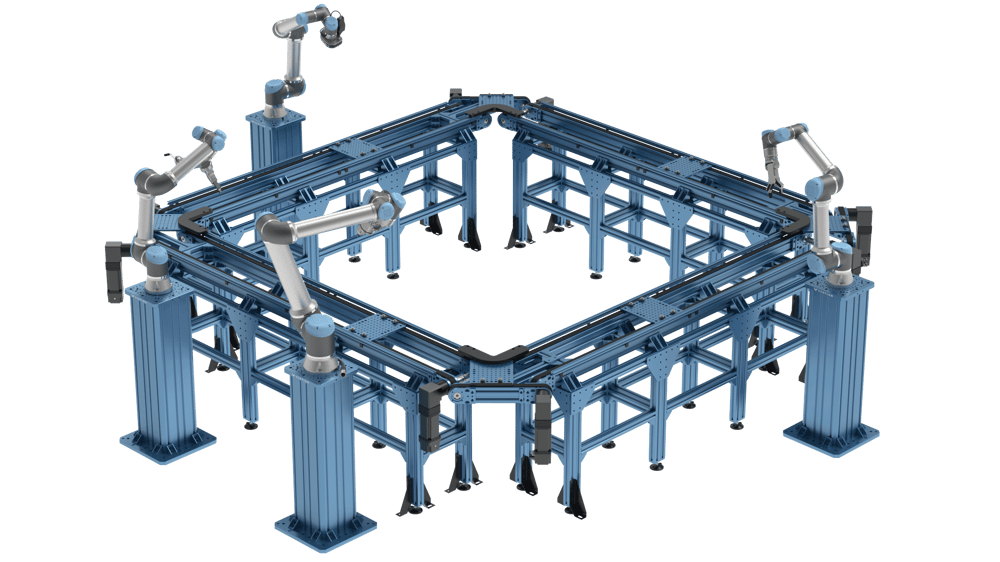

Custom Machines

The cobot pedestal is idea for complex custom machines where robots need to be mounted in close proximity to the machinery.

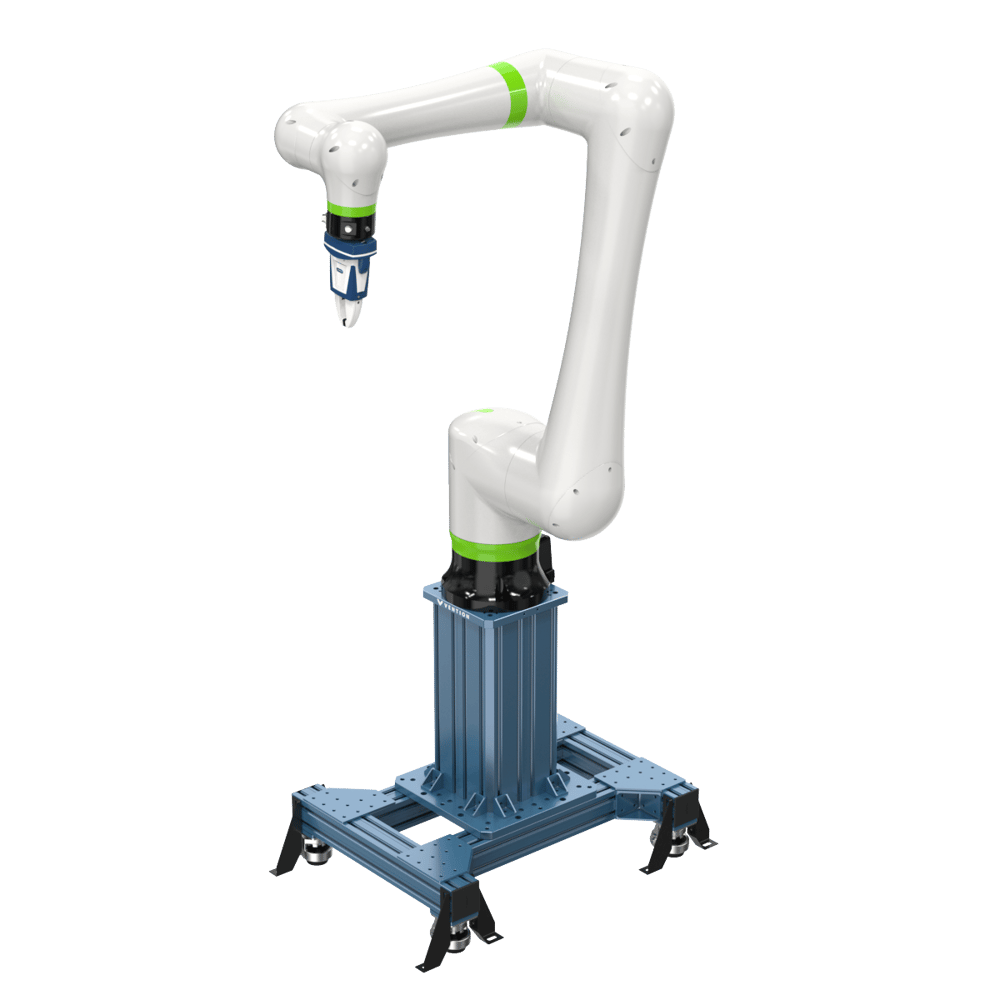

Mobile Pedestals

The pedestal can also be incorporated into simple mobile workstations. Talk to our application engineers to ensure that your mobile setup has sufficient ballast or anchoring to ensure robot stability.

Explore more public designs to get ideas on how you could use the cobot pedestal.

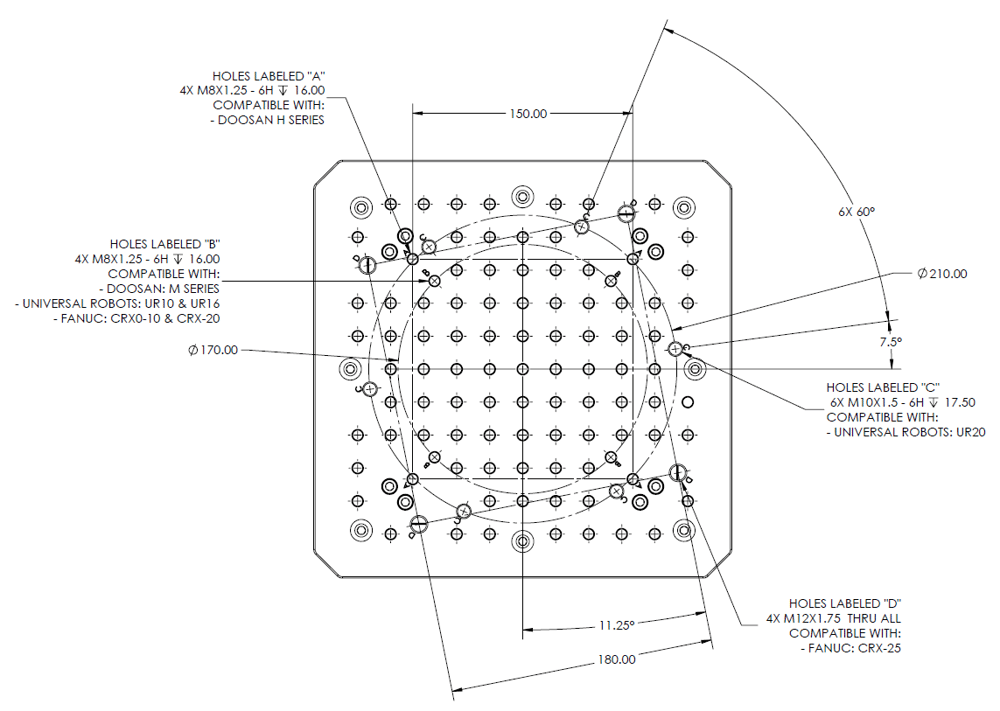

Robot Compatibility

The cobot pedestal is designed to natively support the following robots:

- Doosan

- H2017, Pattern A

- H2515, Pattern A

- M0609, Pattern B

- M0617, Pattern B

- M1013, Pattern B

- M1509, Pattern B

- Epson T6, Pattern A

- Fanuc

- CRX-10, Pattern B

- CRX-20, Pattern B

- CRX-25, Pattern D*

- Universal Robots

- UR10e, Pattern B

- UR16e, Pattern B

- UR20e, Pattern C*

Note: * The mounting angle of the CRX-25 is clocked at 11.25 degrees. The UR20e is also clocked at 7.5 degrees. If you would like to mount these robots orthogonally, see the supported robot plate below.

With use of robot plates the list of compatible robots is expanded to include:

| Robot Supported | Vention Plate Part Number |

|---|---|

| Aubo i5 | ST-RB-003-0001 |

| Aubo i10 | ST-RB-003-0002 |

| Doosan H2017 or H2515 | ST-RB-100-0270 or ST-RB-017-0005 |

| Doosan M0609, M0617, M1013, or M1509 | ST-RB-100-0225 or ST-RB-017-0001 |

| Epson G3 | ST-RB-019-0001 |

| Epson T3 | ST-RB-100-0225 or ST-RB-019-0002 |

| Epson T6 | ST-RB-019-0003 |

| Fanuc CRX-5 | ST-RB-100-0225 or ST-RB-006-2005 |

| Fanuc CRX-10 | ST-RB-100-0225 |

| Fanuc CRX-20 | ST-RB-100-0270 or ST-RB-006-0020 |

| Fanuc CRX-25 | ST-RB-006-0025__2 |

| Fanuc SR-3iA | ST-RB-010-0001 |

| Franka Emika | ST-RB-013-0001 |

| Kuka LRB iiwa 7 R800 | ST-RB-015-0001 |

| Kuka LRB iiwa 14 R820 | ST-RB-015-0002 |

| Omron TM5 | ST-RB-014-0001 |

| Universal Robots UR3 | ST-RB-100-0225 , ST-RB-001-0005, or ST-RB-001-0007 |

| Universal Robots UR5 | ST-RB-100-0225 or ST-RB-006-2005 |

| Universal Robots UR10 | ST-RB-100-0225 or ST-RB-001-0007 |

| Universal Robots UR16 | ST-RB-100-0225 or ST-RB-001-0007 |

| Universal Robots UR20 | ST-RB-100-0270 |

Available Sizes

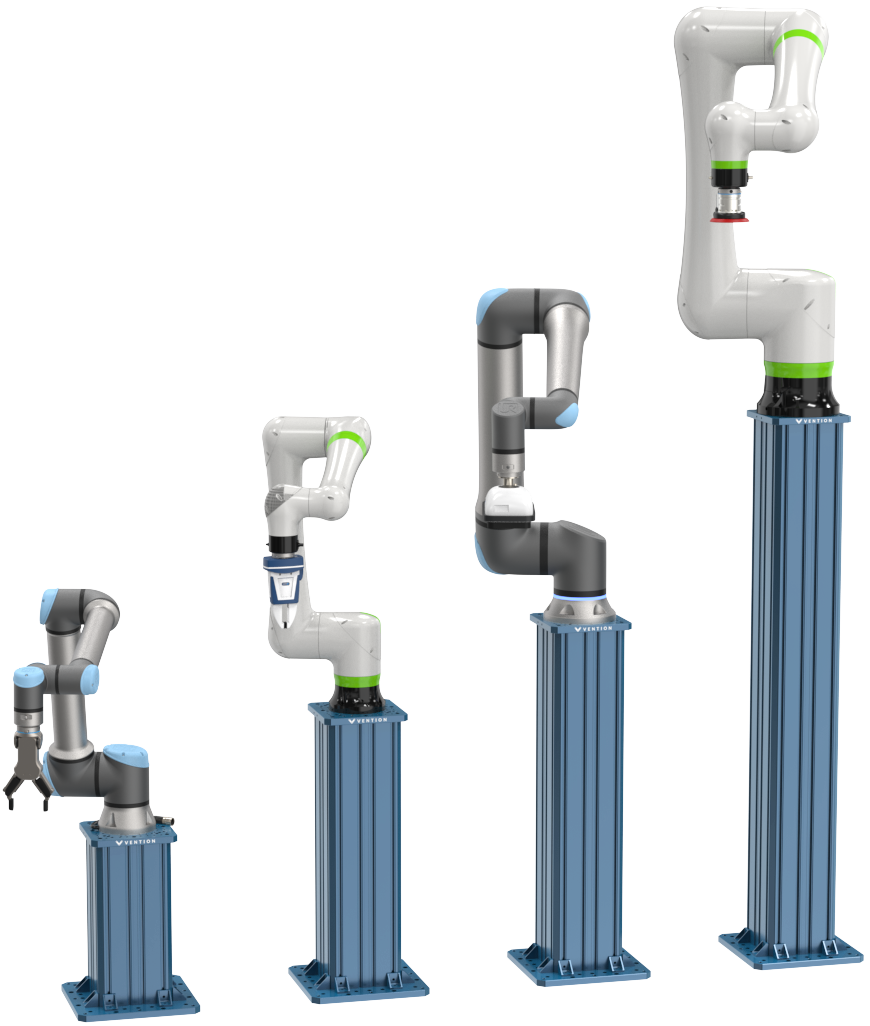

The cobot palletizer comes in 4 heights:

| Part Number | Height (mm) | Weight (kg) |

|---|---|---|

| ST-RB-033-0585__2 | 585 | 27.1 |

| ST-RB-033-0945__2 | 945 | 36.0 |

| ST-RB-033-1215__2 | 1215 | 42.6 |

| ST-RB-033-1890__2 | 1890 | 59.3 |

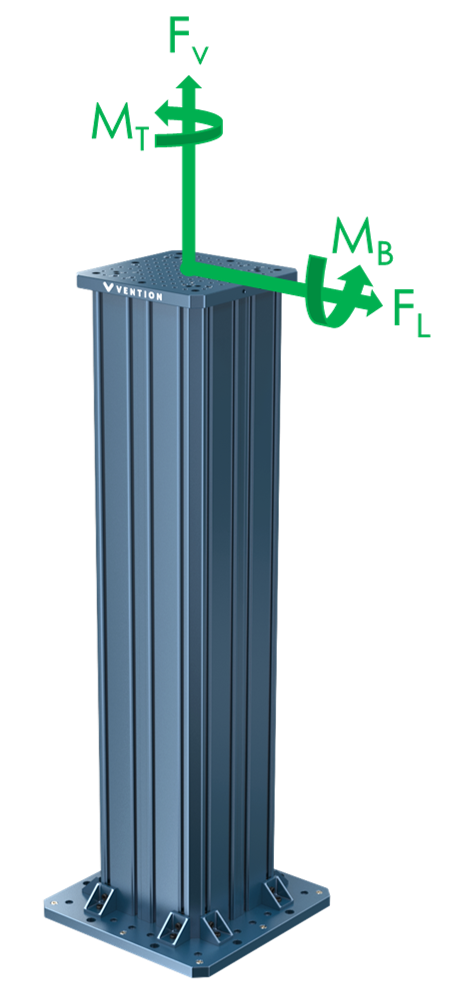

Load Capacity

The table and figure below describe the maximum loads and moments in each direction during operation when the column is either stationary or moving. Continued operation at these maximum values will have an impact on product life.

| Description | Value |

|---|---|

| Max Vertical Force (Fv) | 2500 N |

| Max Lateral Force (Fl) | 1300 N |

| Max Twist Moment (Mt) | 1750 Nm |

| Max Bending Moment (Mb) | 2000 Nm |

Important notes:

- Maximum loading conditions represent the highest possible load applied to the cobot pedestal. These values must be respected during e-stop events. Exceeding these values could cause permanent damage to the pedestal and operator.

- To support these loads the pedestal must be very well secured. Follow the mounting requirements in the assembly instructions section to ensure compliance.

Assembly Instructions

Floor Anchoring

When floor anchoring it is important to consider the surface that the pedestal will be connected too. The cobot pedestal has the ability to be leveled using its jacking screw if your concrete floor is not already flat but use of shims to fill the air gaps in the bolt locations will be necessary. Follow the following steps to floor mount your pedestal.

- With the pedestal in place, use a rotary hammer drill to drill 1/2” holes for the floor anchor kit, ST-RB-033-0002 (not pictured). Note: Anchors must be properly installed into 3000 psi concrete with sufficient thickness. Drill depth should be approximately 3 inches deep.

- Once the anchor holes are drilled and the anchors installed in the holes, the pedestal can be leveled. Use the eight M14 jacking screws included, HW-FN-054-0020 (item 9) to adjust the level of the pedestal, checking in all directions. At this point the nuts on the floor anchors should remain loose to allow leveling.

- Insert shims between the base plate and floor where the anchors are located. This will prevent any movement over time caused by vibration.

- Finally, torque all floor anchors to 68Nm.

Mounting to a Vention Assembly

For mounting to a Vention assembly it is very important to ensure that the structure you are mounting to is itself anchored to the floor or has sufficient ballast so that robot stability is not a concern. Contact one of our application engineers or purchase one of the Vention official designs to be sure of robot stability.

- Check that your extrusion frame is level, square, and that the surface(s) the pedestal base will be mounted on are coplanar.

- Using twelve 25mm long M8 fasteners, HW-FN-003-0025, and t-nuts, connect the base plate to your Vention extrusion frame.

- Torque fasteners to 13Nm.