As the world’s attention turns to reopening their economy, many factories are deploying various solutions to protect their workforce from the coronavirus.

The following post highlights some of the ways manufacturers are leveraging modular hardware to protect their workforce, retool assembly lines ,and ramp up production.

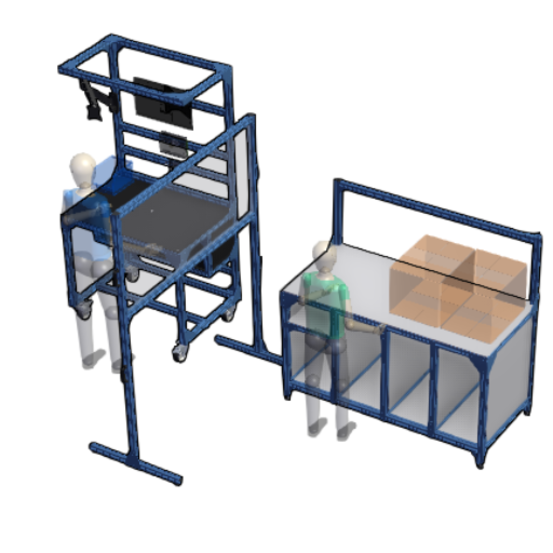

Conveyor Workstation

Retool your factory floor with conveyor workstations. Used in production facilities as part of pick-and-place, dispensing, assembling, and palletizing applications, this modular assembly line limits contact between operators. See the design in MachineBuilder.

Portable Barriers

Physical barriers with clear 1/4’’ polycarbonate panels for areas where operators are forced to be within 6 feet of each other. See the design in MachineBuilder.

Safe Workstation

Adjustable assembly stations with clear 1/4’’ polycarbonate panels for separators. Mobile carts can be fixed to the workstation and easily transferred from one workstation to the next. See the design in MachineBuilder.

Transfer Cart

Safely transfer material between workstations. Clear 1/4’’ polycarbonate panels create a barrier, and sliding drawers prevent contact while operators transfer material. See the design in MachineBuilder.

Cart Conveyor

Cart conveyors can be quickly attached (and detached) from workstations to create modular assembly lines that limit human interaction, protecting the operators health and safety. See the design in MachineBuilder.

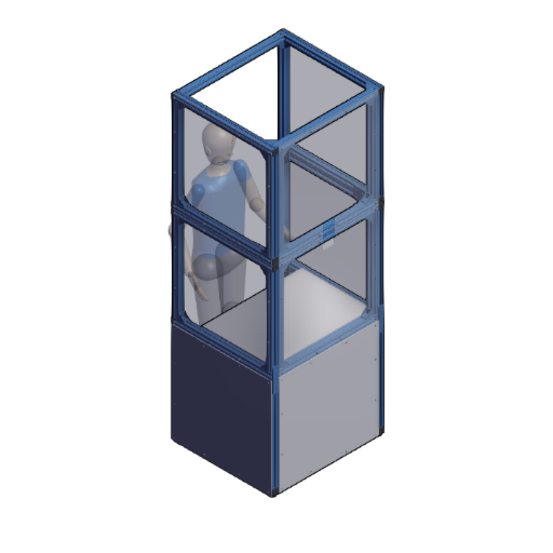

Safe screening booth

Safe screening booths are used in factories and warehouses to temperature check employees when they enter the facility. See the design in MachineBuilder.

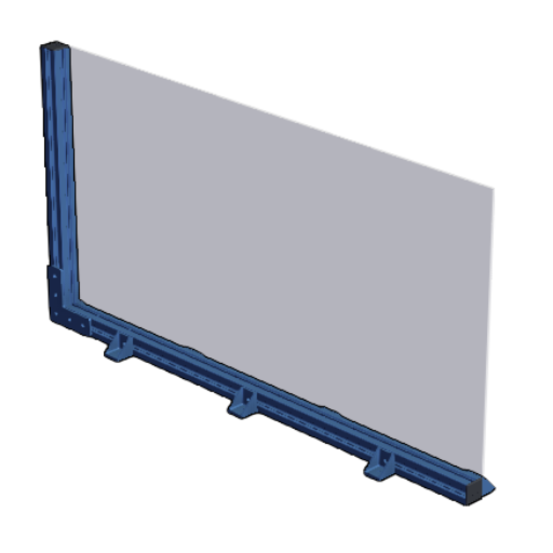

Desk separators

Polycarbonate dividers between and in front of desks to limit the spread of germs and enable greater noise reduction. See the design in MachineBuilder.

For more design ideas or to discuss how modular hardware and automation can accelerate the reopening of your factory, reach out today!