How to guide

Updated: Tuesday, August 10th 2021

Mechanical Assembly Checklist

Overview

The mechanical assembly checklist should be used as a final check once the system is assembled.

Use the following checks to ensure that your system is assembled correctly.

General assembly

| 1. Extrusions | Extrusions are assembled according to CAD design.

|

|

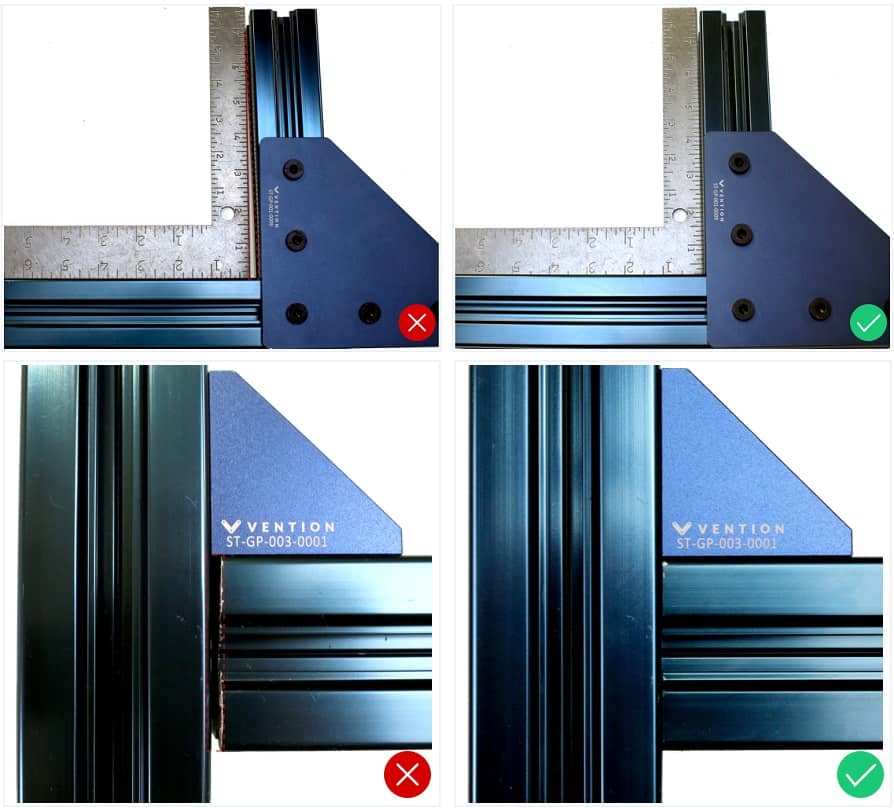

| 2. Gussets | High-precision (HP) and general-precision (GP) gussets are installed in correct locations. | |

| 3. Plates | Assembly plates are properly mounted; no fasteners are missing. | |

| 4. Frame | Base frame can support more than enough weight.

|

|

| 5. Screws | Screws are securely tightened.

|

|

| 6. Level | System is leveled.

|

|

| 7. Cables and tubes | Cables and tubes are sufficiently long and run along clear paths.

|

|

| 8. Hinges | Hinges move smoothly. | |

| 9. Safety interlock | Safety interlocks are adjusted and fully engaged. | |

| 10. Custom parts | Custom parts are deburred and have no sharp edges. |

Rack and pinion

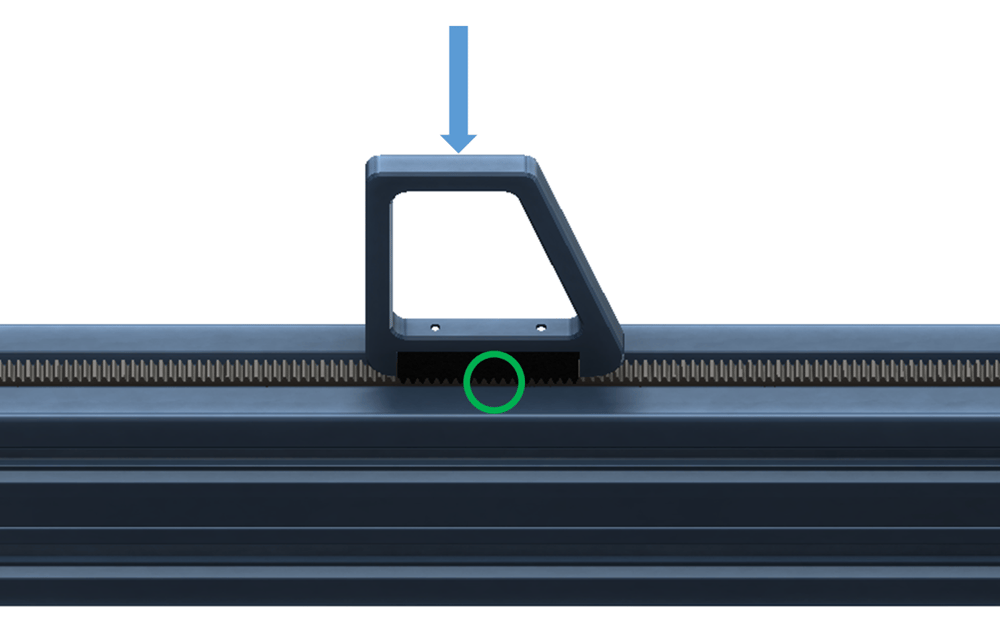

| 11. Rack spacing | Gear rack sections are properly joined.

|

|

| 12. End-stop brackets | End sensor brackets are tightened on rack. | |

| 13. Housing | Bearings and/or rollers are securely mounted on housing. |

Alignment

| 14. Rails |

|

|

| 15. Shaft | If system has butt-jointed rails: Butt-joints have no chamfer, gaps, or misalignment.

|

|

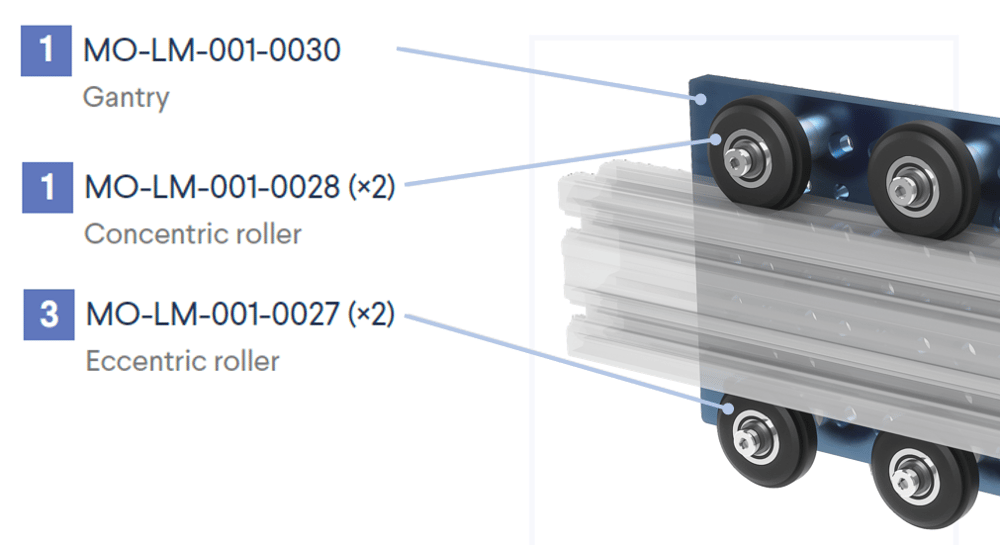

| 16. Roller wheels | Eccentric rollers are all on one side and properly adjusted; concentric rollers are all on the opposite side. For details, see the linear guides datasheet . |

|

Lubrication and maintenance

Find step-by-step instructions for these components in the maintenance guide.

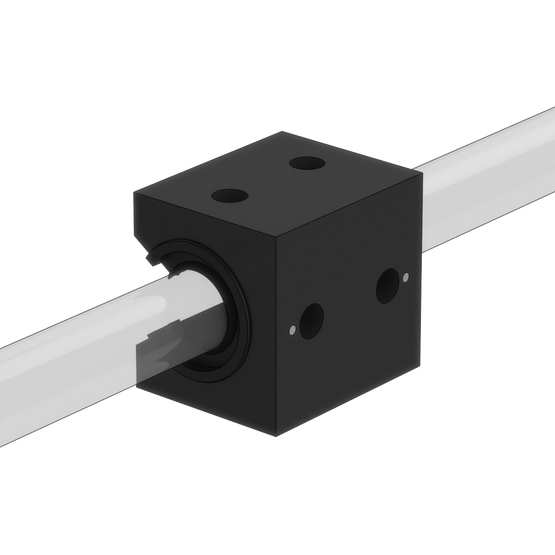

| 17. Linear ball bearings |

Installation: Ball bearings lubricated. Maintenance plan: Linear ball bearings lubricated once a year or after every 100 km of travel, whichever comes first. |

|

| 18. Plain bearings |

Installation (recommended): Shaft cleaned with 3-in-1 oil. No lubrication required for installation or maintenance. |

|

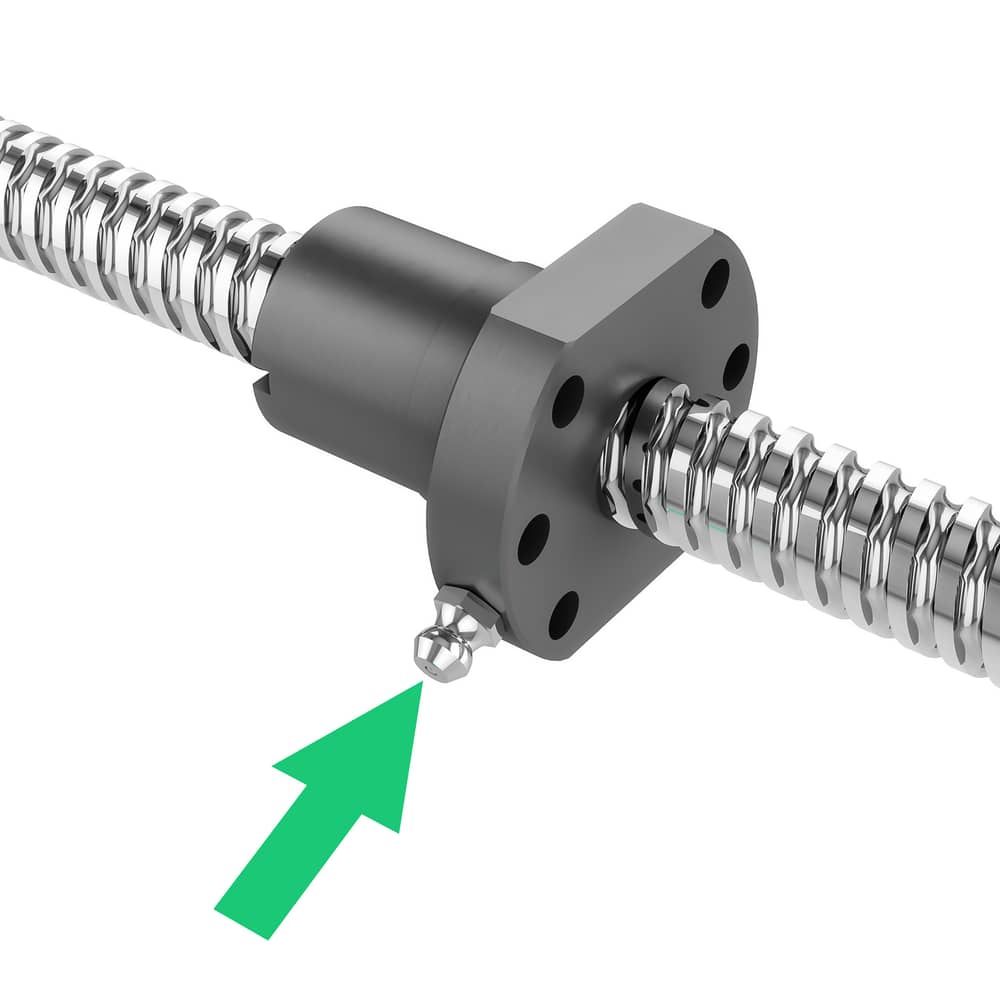

| 19. Ball screws |

Installation: Ball screws lubricated. Maintenance plan: Ball screws lubricated every six months or after 500,000 revolutions, whichever comes first. |

|

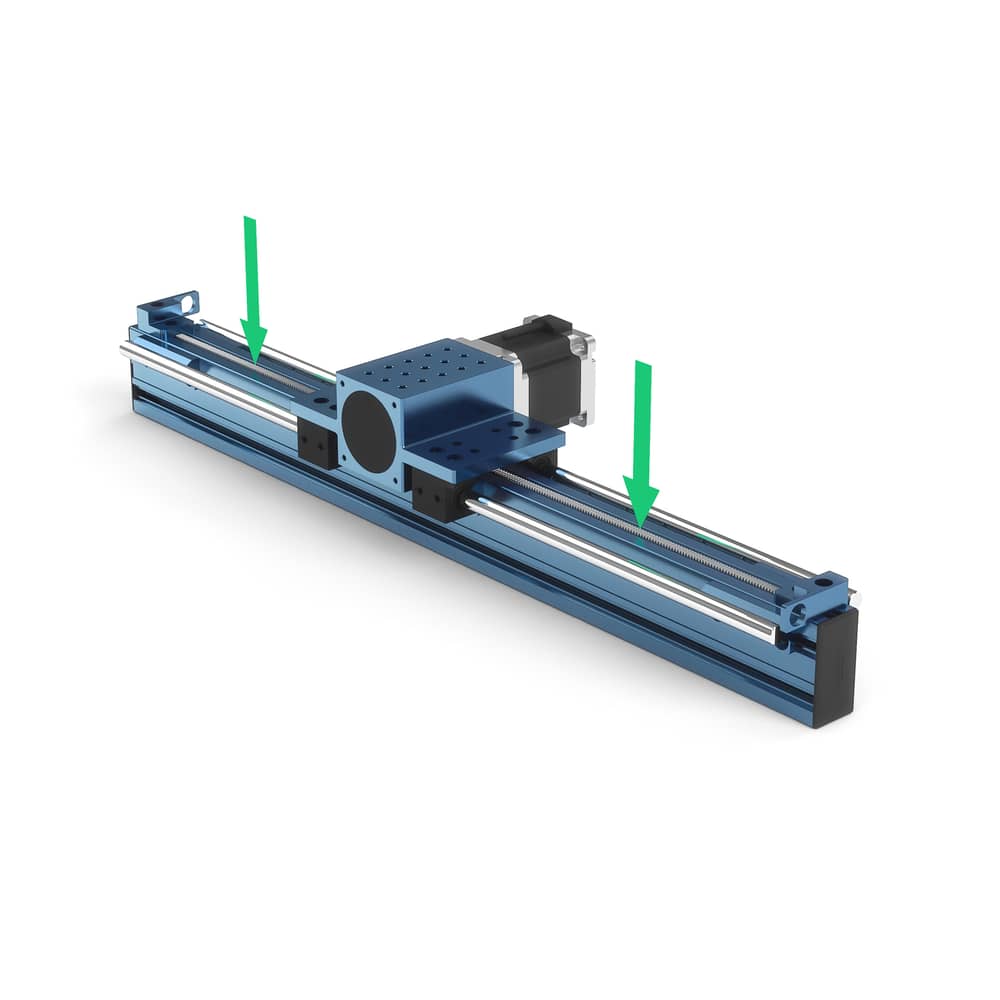

| 20. Rack and pinion |

Installation: Gear racks lubricated. Maintenance plan: Gear racks lubricated every six months or after 500,000 revolutions, whichever comes first. |

|

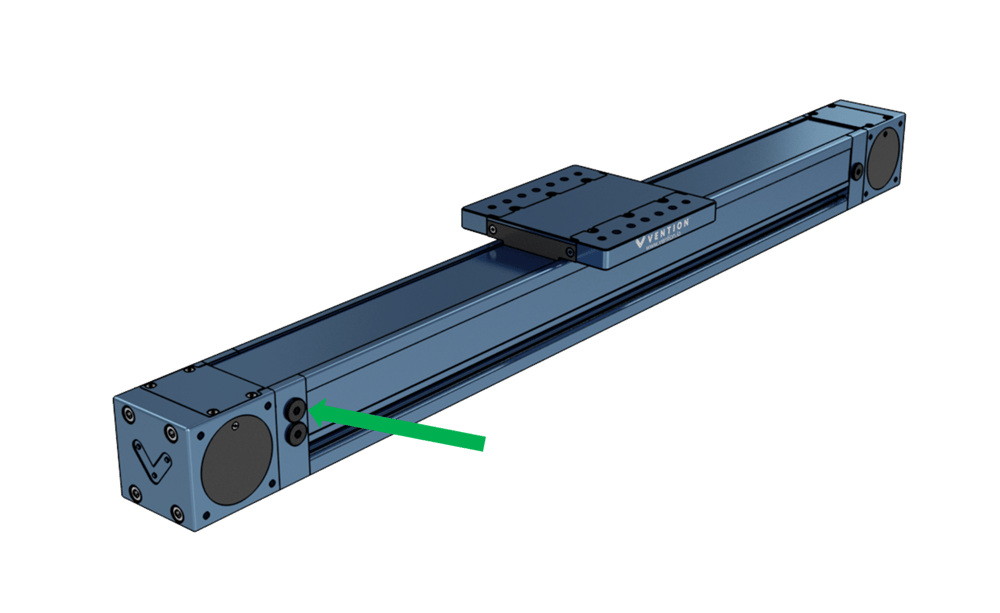

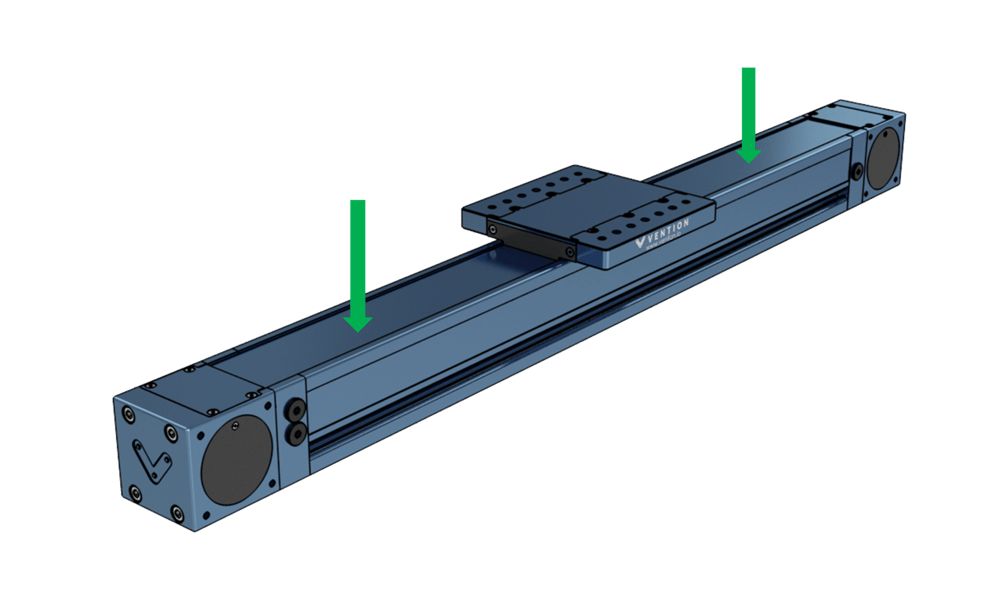

| 21. Enclosed timing belt actuator |

Installation: N/A (ships pre-lubricated). Maintenance plan: Bearings and cover strips lubricated once a year or after every 100 km of travel, whichever comes first. |

|

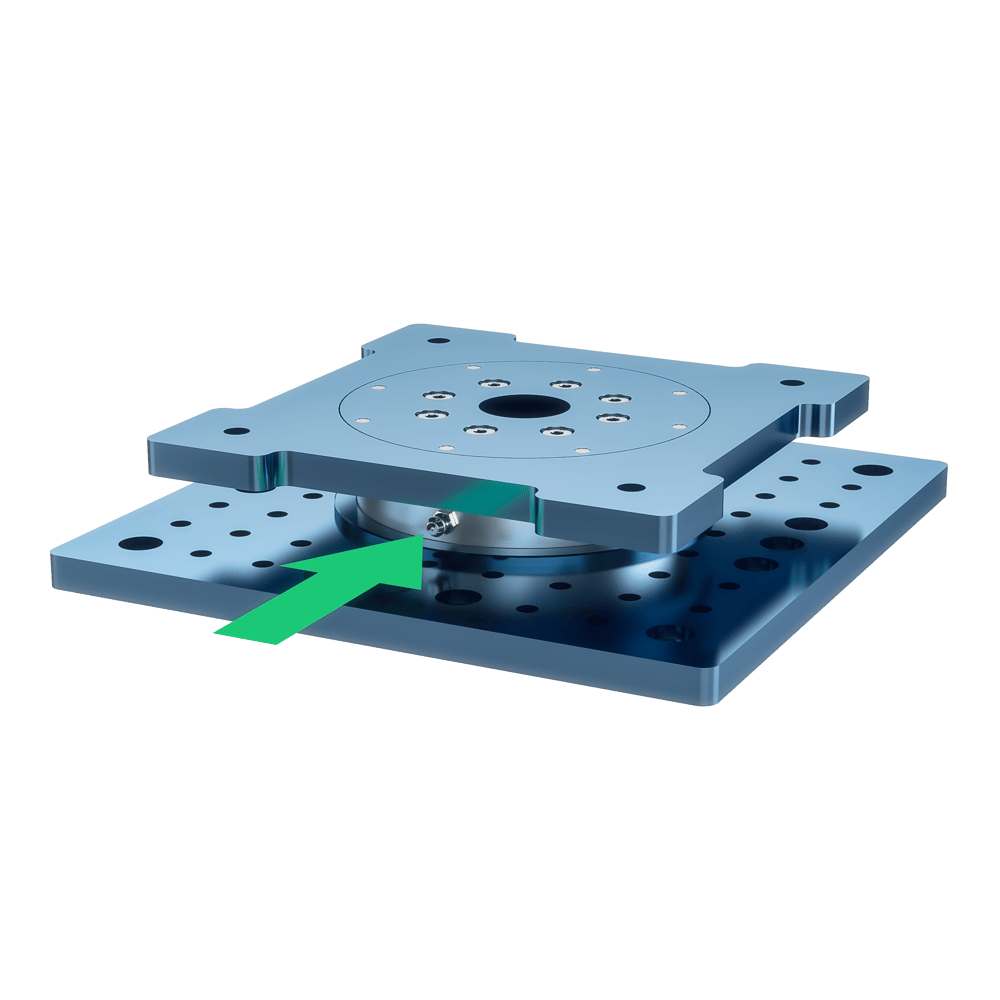

| 22. Rotary actuator |

Installation: N/A (ships pre-lubricated). Maintenance plan: Gears lubricated every six months or after 10,000 revolutions, whichever comes first. |

|

Sensors

| 23. End-stop sensor | If using an actuator: End-stop sensors are functioning (to detect when gantry reaches end of travel). | |

| 24. End-stop bumper | Sensor has sufficient clearance from plate at end-stop position.

|

|

| 25. Sensor mounting | Sensors have enough clearance and are not intercepted by the movement of other components. |

Motors

| 26. Motor | Before installation: Shaft has key installed on it. | |

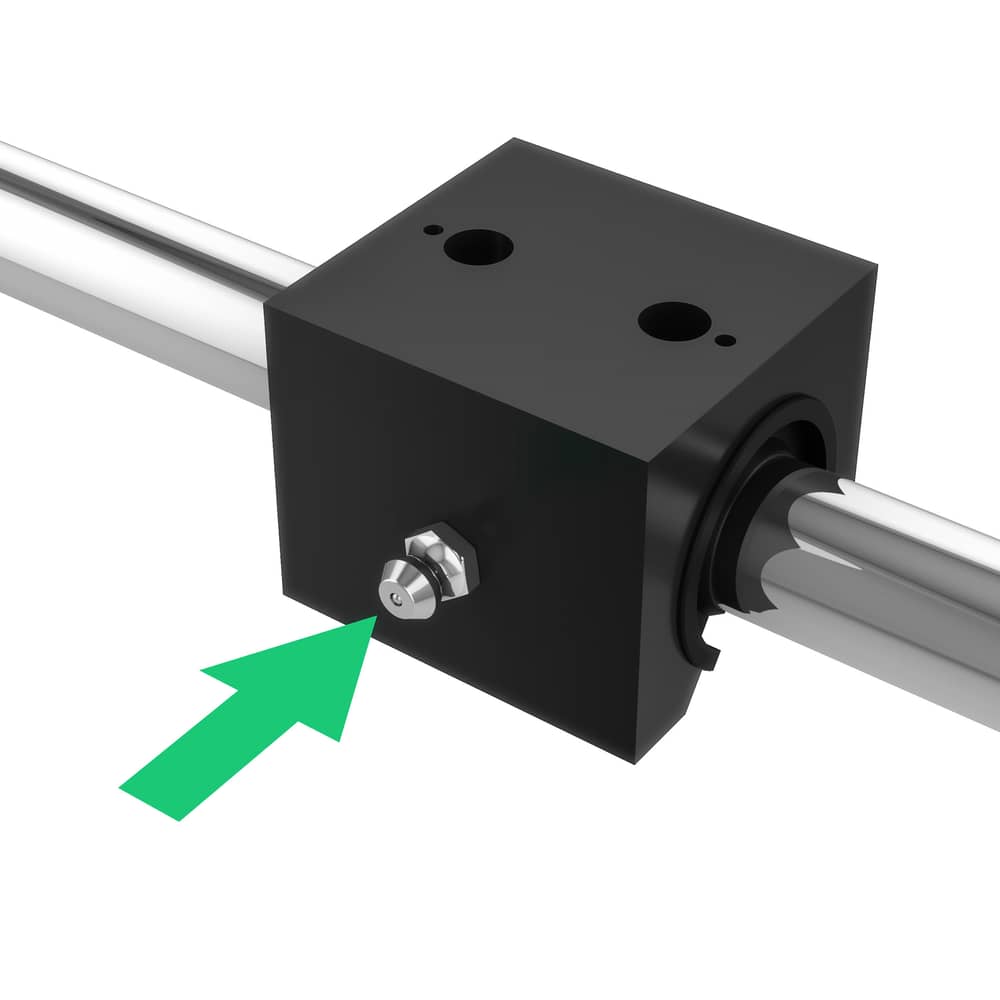

| 27. Power transmission devices |

Before installation: Design follows proper order of motor, gearbox, and brake. If using a gearbox: The input clamping mechanism is properly secured through ports on the gearbox’s side. |