MachineMotion Four-Drive Datasheet

Introduction

MachineMotion v2 datasheet contains detailed technical specifications, such as: functional pinout, input & outputs, specifications, input / output capabilities by model, electronics & embedded software specifications and unit dimensions.

Overview

MachineMotion v2 is a plug and play industrial controller that contains the necessary infrastructure to execute motion and control applications through a library of modular components. Equipment powered by MachineMotion v2 can be programmed through MachineLogic – Vention’s code-free visual sequence editor – or through Vention’s Python SDK.

MachineMotion 1 datasheet can be found in the ‘Documentation for Previous Product Versions’ at the bottom of this page

Features

- Control up to four 250 W high performance step-servos with accurate and automatic position adjustments. This allows the actuator to always reach the user-specified position, thanks to a built-in encoder that enables the motors to operate in closed control loops.

- Step-servo junction box with simple cabling, where the brake, home and end-stop sensors can be directly wired to the motor.

- Status light on servo motors and controller for quick diagnostics

- Loaded with code-free software including:

- Control Center

- MachineLogic

- Python

- Open source development tools including:

- Cloud 9 IDE

- Javascript

- Operator mode

- Manual joggers

- The MachineMotion v2 controller is certified to Canadian, US & European standards.

- IP30 rated enclosure for industrial applications, with active cooling and replaceable filters

- Connect digital I/O and analog modules to control I/O devices

- Supports multiple external communication protocols including MQTT & EtherNet/IP

- Single continuous flex cable to power an actuator, sensors and power-off brake

- Plug and play with all Vention actuators

- Native support for Universal Robots with URcap

- Plug and play safety system with physical and software reset

- Directly connect peripherals locally or remotely using the teach pendant, keyboard, mouse, and monitor

Applications

- Automated equipment

- Cartesian robot

- Functional and reliability test benches

- Conveyor system

- Inspection cells

Supported robot interfaces

- Fanuc

- Universal robots

- ABB

- Doosan

Electrical Specifications

| Certifications | |

| North America |

|

| Europe |

|

| Power Port | |

| Name | POWER |

| Rated Voltage | 85 to 264 VAC |

| Rated Current | 9A @ 120 VAC |

| Typical Current | 4.5A @ 120 VAC |

| Typical Power | 1200 W |

| Standby Current | 0.7 A (@ power factor 0.55) |

| Standby Power | 84 W |

| Emergency Mode Current | 0.4 A (@ power factor 0.3) |

| Emergency Mode Power | 48 W |

| Connector | IEC C14 |

| Power Cord | 3.00m, NEMA 5-15P to IEC 320-C13, SJT |

| Drive Ports | |

| Name(s) | DRIVE 1, DRIVE 2, DRIVE 3, DRIVE 4 |

| Motor Type | Servo-Stepper |

| Output Peak Voltage | 50 V |

| Maximum Output Current | 10 A |

| Maximum Output Power | 350 W |

| Phase Current Peak | 0 - 10 A |

| Phase Current Adjustment (Internal) | Software controlled |

| Control Interface (Internal) | CAN/(Step-Dir-Enable) Signals |

| Motor Drivers Certification | CE |

| Connector | M23 Amphenol Sine |

| Pin 1 | 24 V |

| Pin 2 | 0 V |

| Pin 3 | motor phase A+ |

| Pin 4 | motor phase A- |

| Pin 5 | motor phase B+ |

| Pin 6 | motor phase B- |

| Pin 7 | Encoder A+ |

| Pin 8 | Encoder A- |

| Pin 9 | Encoder B+ |

| Pin 10 | Encoder B- |

| Pin 11 | Encoder Index+ |

| Pin 12 | Encoder Index- |

| Pin 13 | NC |

| Pin 14 | NC |

| Pin 15 | Home/End Limit Switch S1 |

| Pin 16 | Home/End Limit Switch S2 |

| Pin 17 | 24V Safety Switched |

| Control (1,2,3,4) Ports | |

| Name(s) | Control 1, Control 2, Control 3, Control 4 |

| Connectivity Type | Communication |

| Connectivity Physical Layer | CAN/RS485 |

| Connector | M12, female, 8-pin, A-Keyed |

| Pin 1 | 24 V (70W max) |

| Pin 2 | 0 V |

| Pin 3 | RS485 A |

| Pin 4 | RS485 B |

| Pin 5 | CAN H |

| Pin 6 | CAN L |

| Pin 7 | NC |

| Pin 8 | 24V Safety Switched |

| To PC Port | |

| Name(s) | To PC |

| Connectivity Type | Ethernet |

| Connectivity Physical Layer | IEEE 802.3, Ethernet |

| Connector | RJ45 |

| LAN Ports | |

| Name(s) | LAN 1, LAN 2 |

| Connectivity Type | Ethernet |

| Connectivity Physical Layer | IEEE 802.3, Ethernet |

| Connector | RJ45 |

| USB Ports | |

| Name(s) | USB 1, USB 2 |

| Connectivity Type | USB |

| Connectivity Physical Layer | USB 2.0 |

| Connector | USB-A 2.0 |

| HDMI Ports | |

| Name(s) | HDMI |

| Connectivity Type | HDMI |

| Connectivity Physical Layer | HDMI |

| Connector | HDMI Type A |

| Note: drives inside the MachineMotion 2 operate at 48VDC and are designed to power 2-phase stepper motors. They can deliver up to 10A of current per phase. The maximum power consumption for all the drives together is 1000W. Safety In / Pendant Port |

|

| Name(s) | SAFETY IN / PENDANT |

| Type | Redundant Dry Contacts + Reset |

| Connectivity Physical Layer | IEEE 802.3, Ethernet |

| Connector | M12, female, 12-pin, A-Keyed |

| Pin 1 | 24 V (70W max) |

| Pin 2 | 0 V |

| Pin 3 | E-Stop IN Channel 1 Contact 1 |

| Pin 4 | E-Stop IN Channel 1 Contact 2 |

| Pin 5 | E-Stop IN Channel 2 Contact 1 |

| Pin 6 | E-Stop IN Channel 2 Contact 2 |

| Pin 7 | Reset Contact 1 |

| Pin 8 | Reset Contact 2 |

| Pin 9 | Ethernet TX+ |

| Pin 10 | Ethernet TX- |

| Pin 11 | Ethernet RX+ |

| Pin 12 | Ethernet RX- |

| Safety Out Port | |

| Name(s) | SAFETY OUT |

| Type | Redundant Dry Contacts + Reset |

| Connector | M12, female, 12-pin, A-Keyed |

| Pin 1 | NC |

| Pin 2 | 0 V |

| Pin 3 | E-Stop OUT Channel 1 Contact 1 |

| Pin 4 | E-Stop OUT Channel 1 Contact 2 |

| Pin 5 | E-Stop OUT Channel 2 Contact 1 |

| Pin 6 | E-Stop OUT Channel 2 Contact 2 |

| Pin 7 | Reset Contact 1 |

| Pin 8 | Reset Contact 2 |

| Pin 9 | NC |

| Pin 10 | NC |

| Pin 11 | NC |

| Pin 12 | NC |

| Ethernet Port | |

| Name(s) | ETHERNET |

| Connectivity Type | Standard Ethernet |

| Physical Layer | IEEE 802.3, Ethernet |

| Connector | RJ45, 8p8c |

| Pin 1 | NC |

| Pin 2 | TX+ |

| Pin 3 | TX- |

| Pin 4 | RX+ |

| Pin 5 | RX- |

| Pin 6 | NC |

| Pin 7 | NC |

| Pin 8 | NC |

| Default Ethernet or 192.168.7.2 Port | |

| Name | DEFAULT ETHERNET or 192.168.7.2 |

| Status | Unused |

Embedded & Computing Specifications

| Single Board Computer | |

| Processor | TI AM5729 |

| OS | Debian 10 |

| Memory | 32GB SD-micro |

| Certification | CE |

| Motion Controller | |

| Processor | Natotec CL4 |

| Interface | CAN |

| Protocol | G-code |

| Fieldbus Compatible Modules | |

| Digital IO Module | CE-MD-001-0001 |

| Analog IO Module | CE-MD-003-0000 *available soon |

| Push-Button Module | CE-MD-004-0000 |

Safety Specifications

| Safety PLC | |

| Manufacturer | ReeR |

| Model Number | M1 |

| Safety Data - Values per EN ISO 13849-1 | |

| Category | 3 |

| Performance Level | PLe |

| MTTFd | 64 years |

| DCavg | 97.3 % |

| PFHD | 8.84E-08 h<>-1 |

| Safety Data - Values per IEC/EN 61508 | |

| SIL | 2 (IEC/EN 61508) |

| HFT (hardware failure tolerance) | 1 |

| DCavg | 97.3% |

| SFF | 99.70% |

| PFHD | 1.45E-08 h<>-1 |

| Operation conditions | |

| dop | 365 days/year |

| hop | 24 hours/day |

| Tcycle | 8640 s/cycle |

Vention ControlCenter Software

MachineMotion comes with pre-loaded control and machine operations software – all of which is accessible through the MachineMotion pendant or via computer with a USB or Ethernet connection.

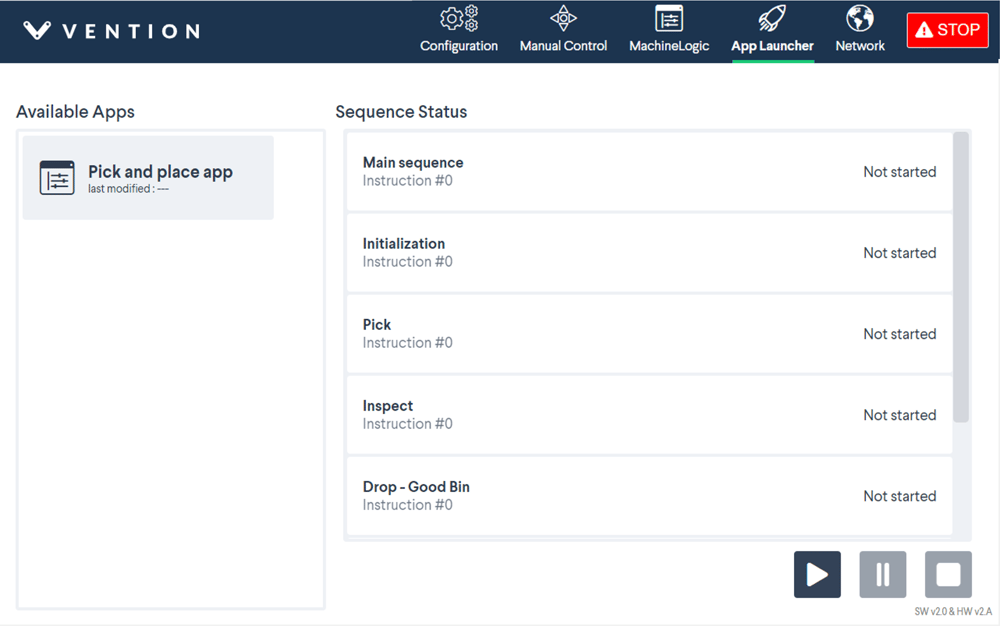

Application Launcher

- Launch MachineLogic Applications

- Launch Python Applications

- Configure programs in auto-launch mode (executes automatically after power-ON)

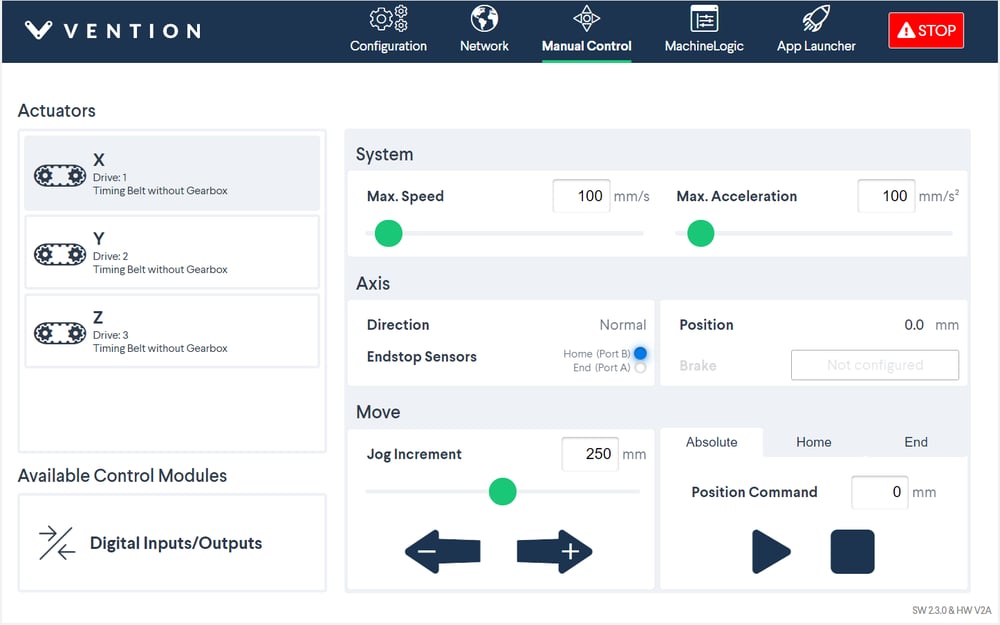

Manual Control

- Send motion commands to actuators

- Configure speed, acceleration and direction

- Monitor the state of end-of-travel sensors and connected control devices

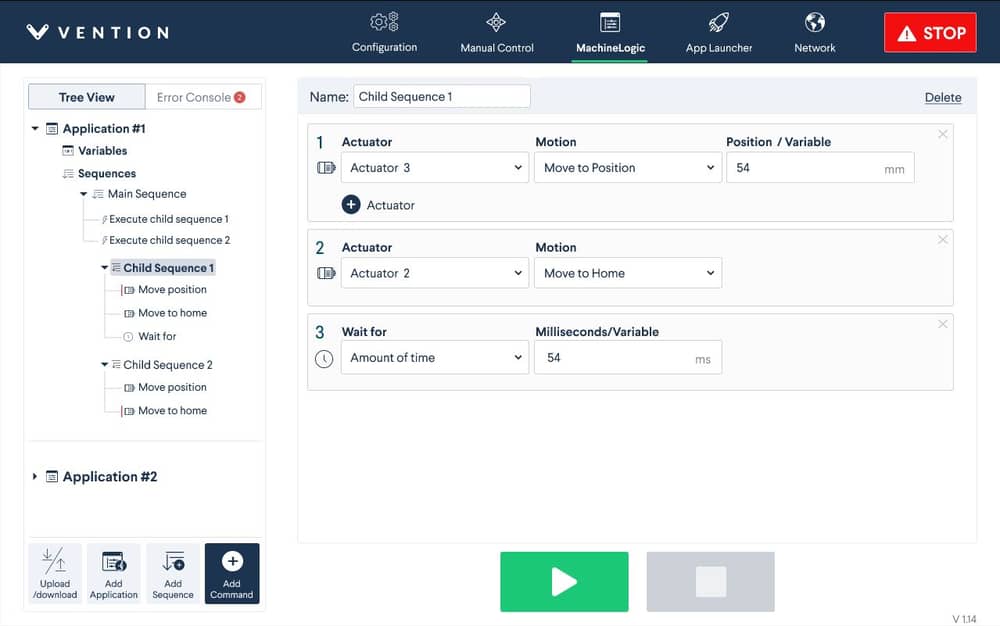

MachineLogic

- Create automation programs in a simple graphical interface

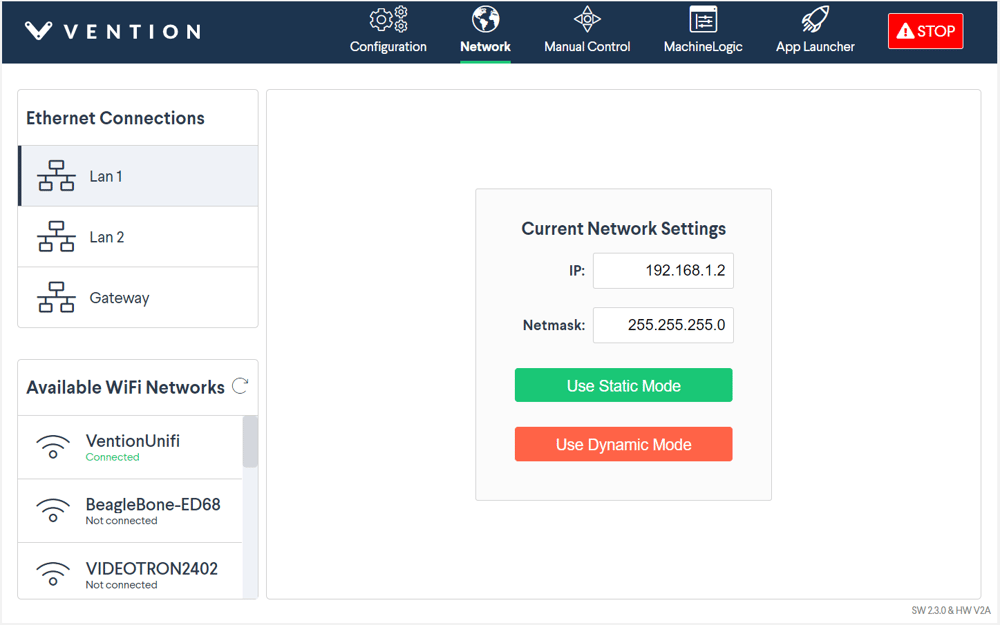

Network Configuration

- Configure the Ethernet ports and WiFi settings (only if the MachineMotion controller is connected to a MachineMotion pendant)

Software & Communication Protocol Specifications

| Available Control API |

| Python |

| Communication Protocol for Ethernet Adapter |

| web-socket |

| Communication Protocol for Fieldbus |

| MQTT |

| Security |

| MachineCloud connection is encrypted (TLS 1.2 & TLS 1.3, A-rated ciphers, RSA 2048-bit keypairs on server and client) |

Physical Unit

Functional Pinout

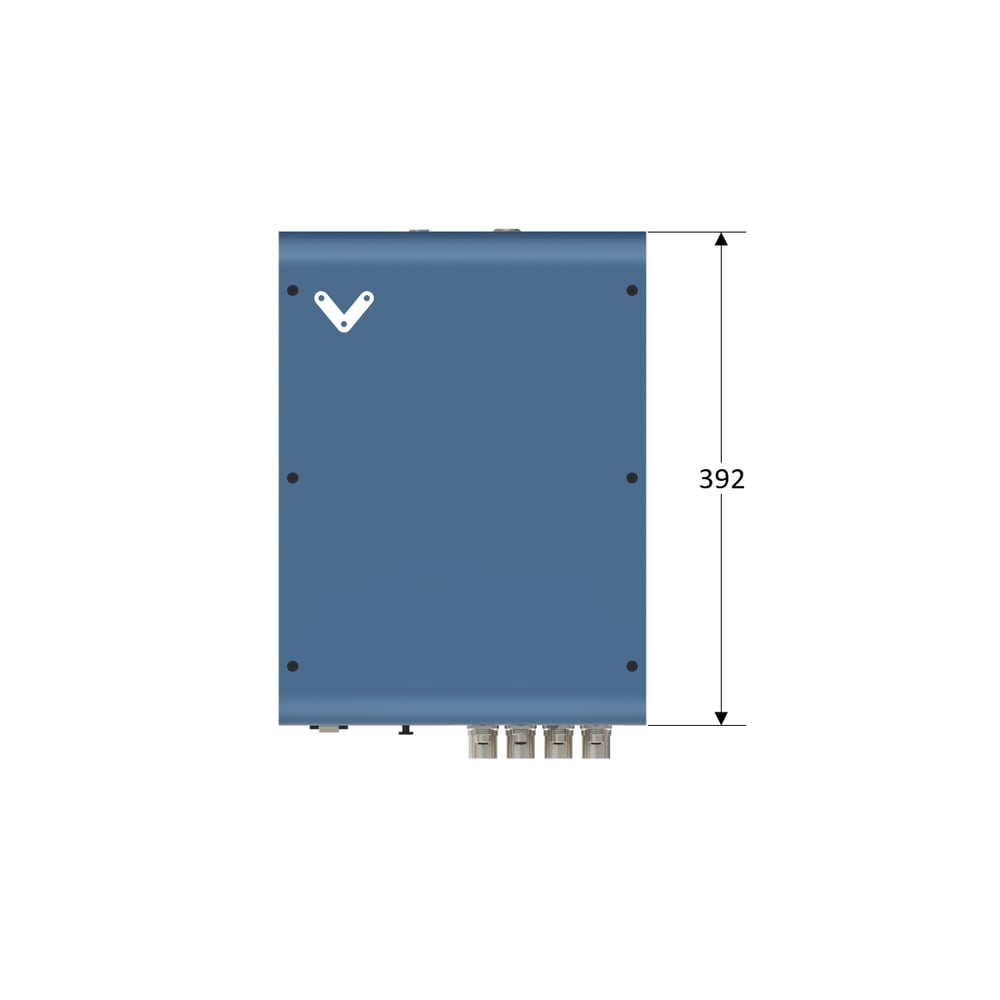

Unit Dimensions

Compatible Hardware

Plug and Play Automation Components

| MachineMotionTM Pendant CE-TP-004-0001

|

M18 Inductive Proximity Sensor CE-SN-004-0001

|

| Digital I/O Module CE-MD-001-0001

|

Power-Off Brake MO-PT-002-0001

|

| NEMA34 Servo Motors MO-SM-01X-0000

|

Emergency Stop and Reset Module CE-SA-007-0000

|