ABB - Robot Configuration for MachineLogic Applications

ABB - Robot Configuration for MachineLogic Applications

Overview

This document provides step-by-step instructions for configuring and using an ABB GoFa robot with MachineLogic. This integration ensures seamless operation within Vention’s motion components ecosystem. Robots purchased through the Vention platform are pre-configured for a simple and efficient setup experience.

Supported Models

The following ABB robot models are supported when used with the Omnicore C30 controller, which is required for compatibility with Vention’s MachineLogic:

- GoFa 5

- GoFa 10

- GoFa 12

Installation Steps

The robot and it’s controller are shipped from factory pre-configured to ensure ease of deployment. Therefore, only a few steps are required in order to be up an running with your MachineLogic application. To continue with the next steps, ensure all the components you received with your order are out of their shipping boxes. Once this is completed, proceed to the next section.

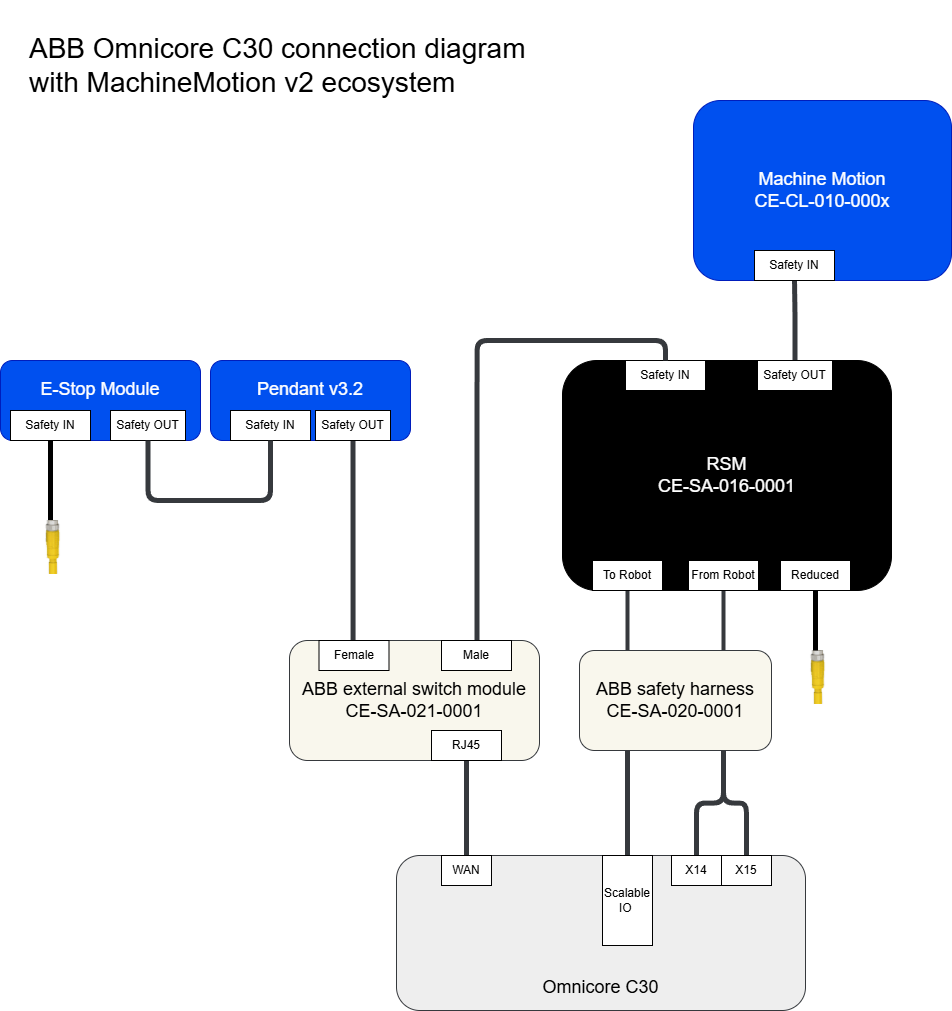

System Connection

To program the robot through MachineLogic, the MachineMotion must be connected to the Omnicore C30 controller and the necessary safety ecosystem. This guide will define the necessary steps for a basic safety configuration.

Necessary Components

- MachineMotion v2 (1 Drive or 4 Drives)

- Vention Pendant

- E-Stop Module with reset

- ABB GoFa Robot

- Omnicore C30 Controller

- Robot Safety Module

- ABB external switch module

- ABB safety harness

Connection Diagram

Bellow is a diagram to demonstrate how to connect each component for a successful installation.

Please note that this diagram represent a basic safety configuration and could change if more safety components are needed in the safety chain.

Power Up

After connecting all components, power up the devices in the following order:

- Turn on the MachineMotion.

- Turn on the Vention Pendant

- Turn on the Omnicore C30 controller using its main switch.

Devices Initialization

Once all devices are properly connected and powered up, we will then proceed to the intialization of each devices to ensure they will function properly.

ABB FlexPendant

Follow these steps to set up the ABB FlexPendant:

- Login as Admin on the FlexPendant

- Open the Control Panel from the navigation bar

- Go to the Logout/Restart menu

- Click on Logout

- When prompted, login with the admin credentials:

- Username: admin

- Password: robotics

- Click on Log In

- Set the operation mode of the robot to Manual:

- Open the Control Panel from the top navigation bar.

- Go to the Control menu

- Set operational mode to Manual

- From the Home page, navigate to Settings -> Safety Controller -> Synchronization.

- Enable the motors using the dead man switch in the middle position.

- Enable Move to Sync Position.

- Press and hold the button to move the robot to its home position. (Warning: The robot will move.)

- Once the robot’s Actual Positions match the Sync Positions, press Synchronize.

- Open the Control Panel from the top navigation bar.

- Set the mode to Auto under Control -> Auto to allow MachineMotion to control the robot.

Vention Pendant

Ensure your MachineLogic application and configuration are deployed before proceeding. Refer to How to Deploy your Application to the MachineMotion.

- Validate the configuration:

- Click Configuration on the navigation bar.

- Confirm that the robot appears and the correct model is selected from the dropdown.

- Click Apply Configuration.

- Test system control over the robot:

- Use the robot jogger found under Manual Control on the Vention Pendant to ensure functionality.

Completion

You have now completed the setup process. Your robot is ready to run applications programmed in MachineLogic.

Additional Informations

This section contains advanced information regarding the ABB robot.

Admin Log In

Some advanced configuration can only be done with the admin credentials. Either on the FlexPendant or using ABB’s RobotStudio.

Username: admin

Password: robotics

Modifying the Collaborative Mode Delay

⚠️ Important Safety Notice

Modifying this delay requires approval from a safety engineer and must follow a formal safety risk assessment.

#Steps to Modify the Delay:

- Open RobotStudio on your computer.

- Connect your computer to the robot controller via an Ethernet cable in the MGMT port.

- In RobotStudio, navigate to the Controller tab and click on:

-

Add Controller → One Click Connect

-

Add Controller → One Click Connect

- Once connected, authenticate as Admin. (Refer to authentication instructions if needed.)

- Click Request Write Access, then Grant Write Access on the FlexPendant.

- In the main menu, click Safety to access the Safety Configuration.

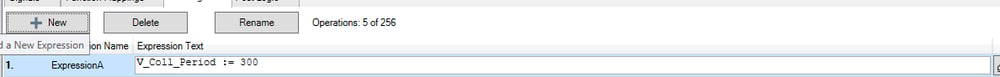

- Navigate to Safe IO Configuration → Pre-Logic → + New.

-

Define the expression for the collaborative delay:

-

Enter the following expression (Example: 300):

V_Coll_Period := 300 -

To calculate the required delay, use the formula:

V_Coll_Period = (TimeInSeconds - 0.015) / 0.003883 -

Example: If the desired delay is 500ms, use:

(0.5 - 0.015) / 0.003883 = 124.9 -

Click Create Missing Formula.

-

- The new expression should now appear in the list.

- To apply the new configuration, click Controller → Write to Controller.

- Restart the controller as prompted to complete the update.

Support

For further assistance, contact our support team:

- Email: support@vention.io

- Phone: +1-1800-940-3617 (ext. 2)