- Resource Library

- MachineMotion

- Controller Peripherals

- Keyence Laser Scanner & Light Curtain User Manual

Keyence Laser Scanner & Light Curtain User Manual

Overview

Safety devices are essential for a safe work environment. They can be used in various configurations to monitor safety zones where access is limited. Only one safety device (laser scanner or light curtains) can be connected to Vention’s Safety Module at a time. If you need to interface N number of safety devices to MachineMotion V2, you will need N number of safety modules (daisy-chained). Please refer to the User Manual for more information about the connections.

Connecting to MachineMotion 2

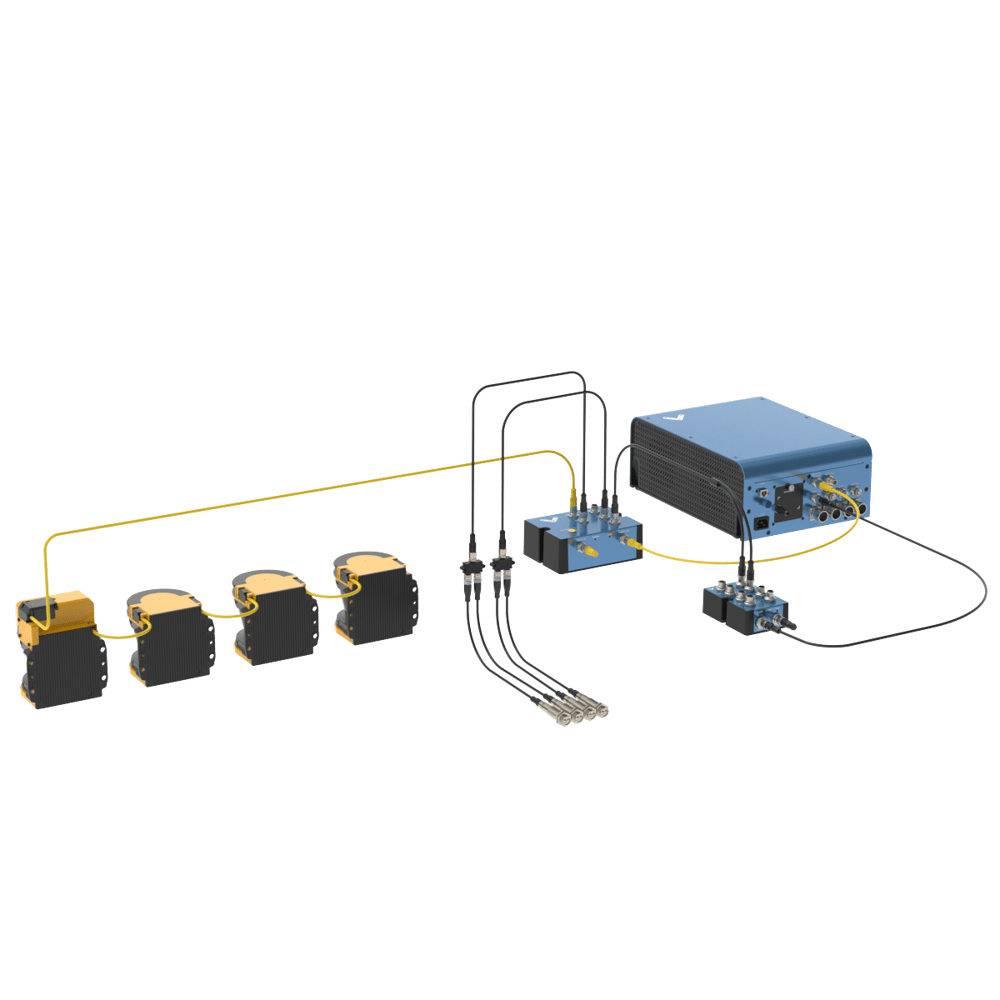

Keyence SZ-V Laser Scanner to MachineMotion 2

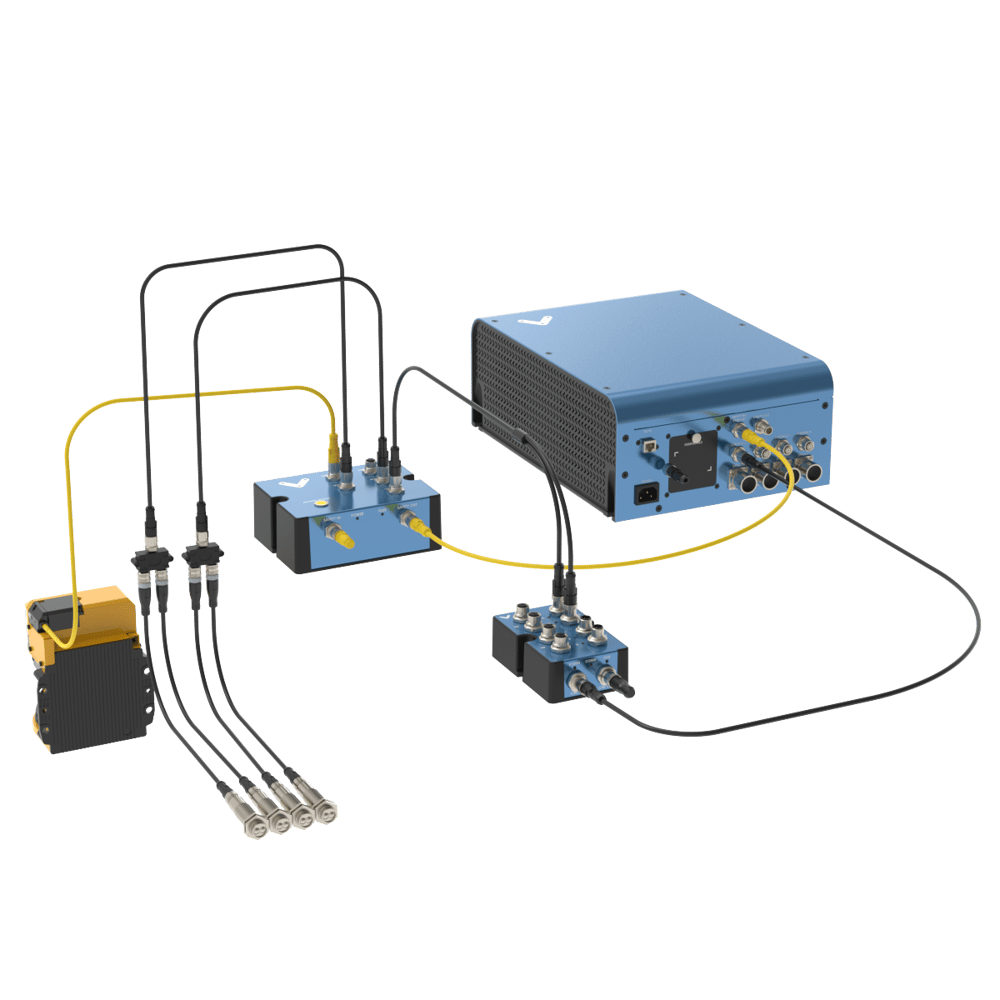

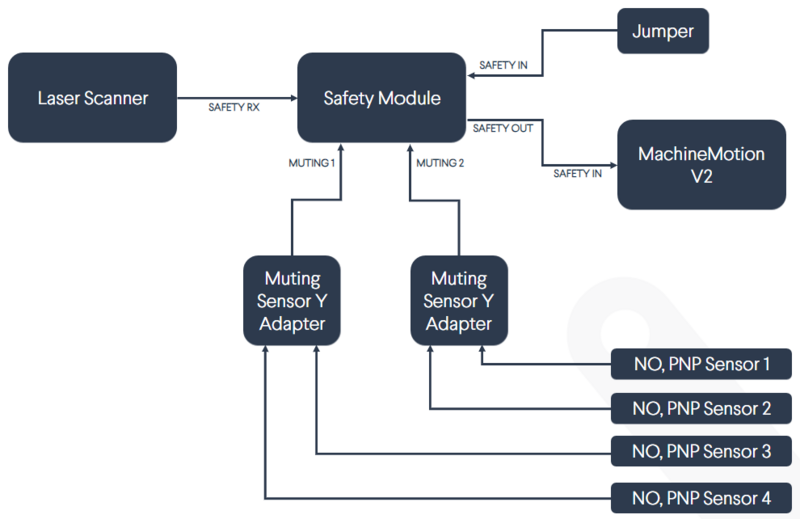

The steps to connect the Laser scanner to MachineMotion 2 via the Safety Module are as follows:

- Connect the Keyence Laser Laser scanner - Parent (Safety Module Compatible) to a Safety Module (CE-SA-008-0000__3) through the SAFETY RX connector using the Keyence SZ-V Laser scanner Power cable 5m to M12-12 Male Cable (CE-SA-120-0001).

- Connect a MachineMotion 2 Safety Extension Cable (CE-CA-102-5001) to the Safety Module’s SAFETY OUT connector and MachineMotion 2’s SAFETY IN connector.

- If muting is required, connect the muting sensor in pairs to the Muting Sensor Y Adapter. Then connect the adapter to the Safety Module via the MUTING 1 and/or MUTING 2 connectors. Safety Module Muting Kit (CE-AP-002-0000) is not included with the Safety Module.

- If bank switching is required, connect the Bank Switching Cable for Safety Module and DIOv2 (CE-CA-067-5000) to the CTRL IN connector on the Safety Module and to the Digital IO Module V2 (CE-MD-001-0000__2) outputs. Bank Switching Cable for Safety Module and DIOv2 (CE-CA-067-5000) and Digital IO Module V2 (CE-MD-001-0000__2) are not included with the Safety Module

Note: If no other safety devices are being daisy-chained to the Safety Module, a safety jumper (CE-SA-102-0001) must be used on the Safety Module’s SAFETY IN connector.

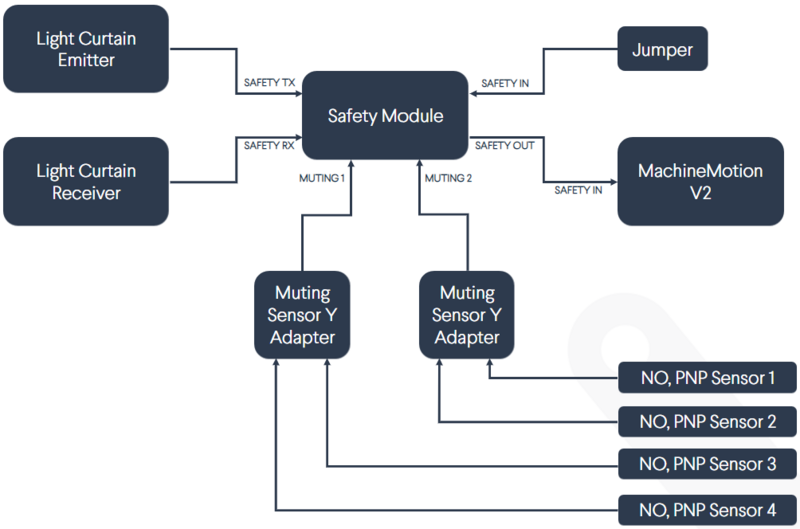

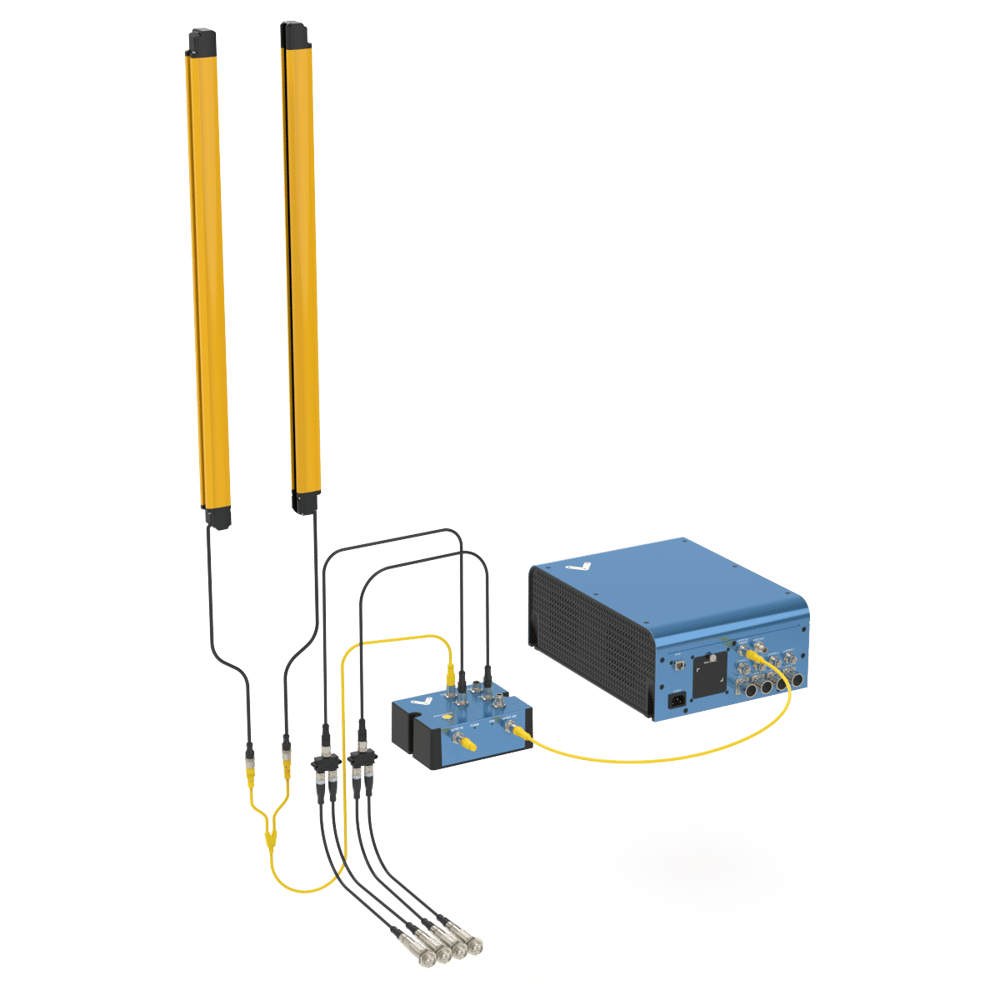

Keyence GL-R Light Curtains to MachineMotion 2

The steps to connect Keyence GL-R Light Curtains to MachineMotion 2 via the Safety Module are as follows:

- Connect the receiver and the emitter to CE-SA-118-0001 cable using 2 × CE-SA-119-0001 (one for the receiver and one for the emitter). Then, connect CE-SA-118-0001 to the Safety Module on SAFETY RX connector.

- Connect a MachineMotion 2 Safety Extension Cable (CE-CA-102-5001) to the Safety Module’s SAFETY OUT connector and MachineMotion 2’s SAFETY IN connector.

- If muting is required, connect the muting sensor in pairs to the Muting Sensor Y Adapter. Then connect the adapter to the Safety Module via the MUTING 1 and/or MUTING 2 connectors. Safety Module Muting Kit (CE-AP-002-0000) is not included with the Safety Module.

Note: If no other safety devices are being daisy-chained to the Safety Module, a safety jumper (CE-SA-102-0001) must be used on the Safety Module’s SAFETY IN connector.

Keyence Laser Scanner SZ-V04 (Parent) & SZ-VH1 (Child)

Description

The Keyence Laser Scanner (SZ-V04 ) is an essential tool to ensure safety in the workplace. It can be used in multiple orientations to monitor large areas while remaining discreet and unobstructive. It will stop a machine if any undesired person or object crosses its safety zone. It features a couple of useful functionalities such as muting; automatically deactivates the safety status of the whole system (total muting) or part of it (partial muting) to let material pass through. Another useful function is bank switching; ability to switch between two zone configuration (useful for muting two zones independently). A PC with an Ethernet port is required for configuration.

In order to use the Laser Scanner with MachineMotion2, a Safety Module (CE-SA-008-0000__3) is required, please refer to the safety installation guideline section for the wiring.

The Laser Scanner specifications are as follows:

- Maximum safe zone: 8.4 m radius.

- Maximum warning zone: 26 m radius.

- Detection angle: 190°.

- Total/partial dynamic muting optional kit available (CE-AP-002-0000).

- Zone switching (bank switching) available with the purchase of the CE-CA-067-5000 cable.

Getting Started

- Assemble the Laser Scanner bracket and mount it at the desired location.

- Download the latest version of KEYENCE Safety Device Configurator software here

- Install the KEYENCE Safety Device Configurator by following the installation instructions

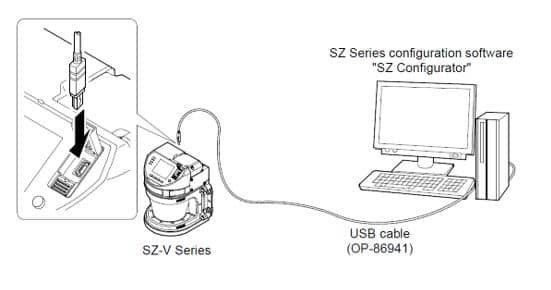

- Connect the laser scanner to PC using the provided USB cable

- Power the MachineMotion controller

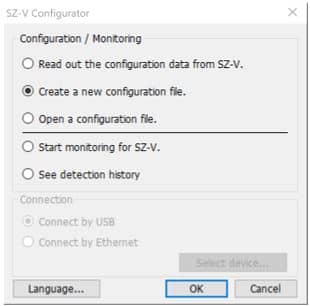

- While the laser scanner is powered, open the KEYENCE Safety Device Configurator

- Select Create a new configuration file and click OK

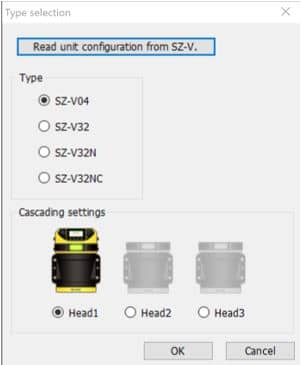

8. Select the model of the laser scanner you have (SZ-V04 for parent, SZ-VH1 for child) and click OK

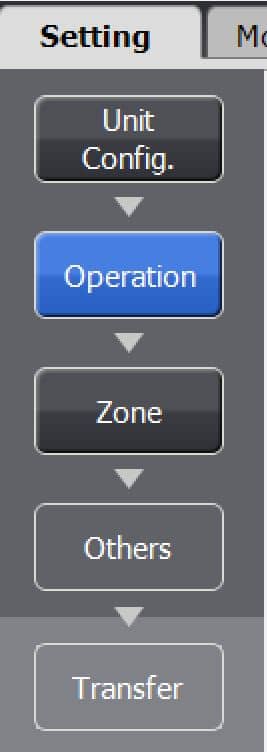

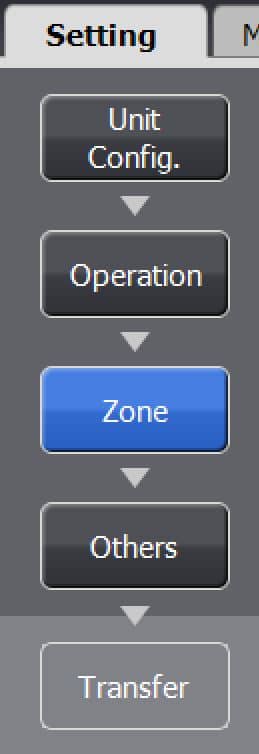

9. In the Setting menu, select on Operation

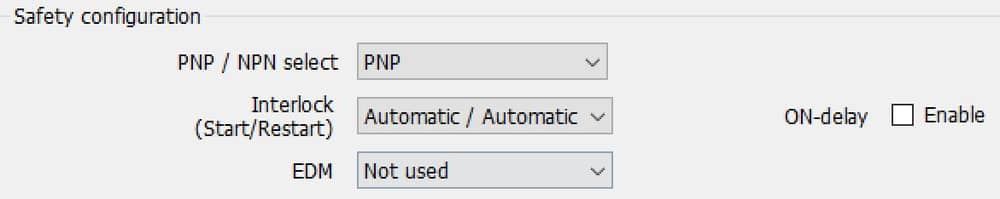

10. In the Safety configuration section, select the compatible input type as PNP and Interlock as Automatic/Automatic (when used with a Vention Safety Module), leave EDM as Not used

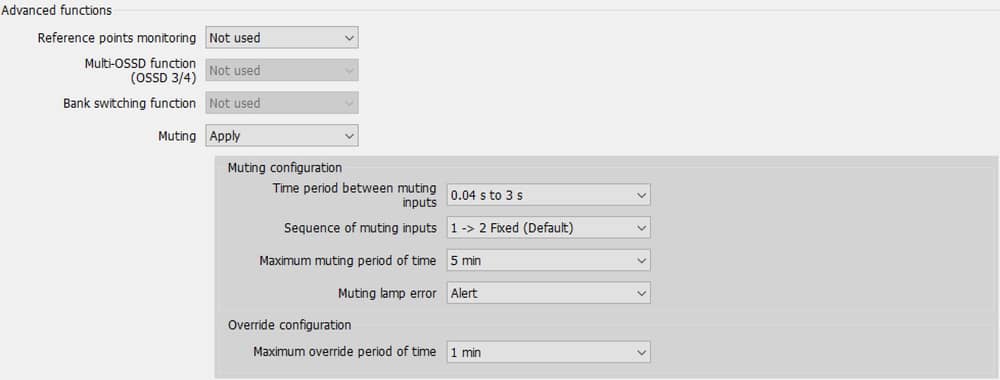

11. Go to the Advanced functions section and enable Muting as shown in the picture below.

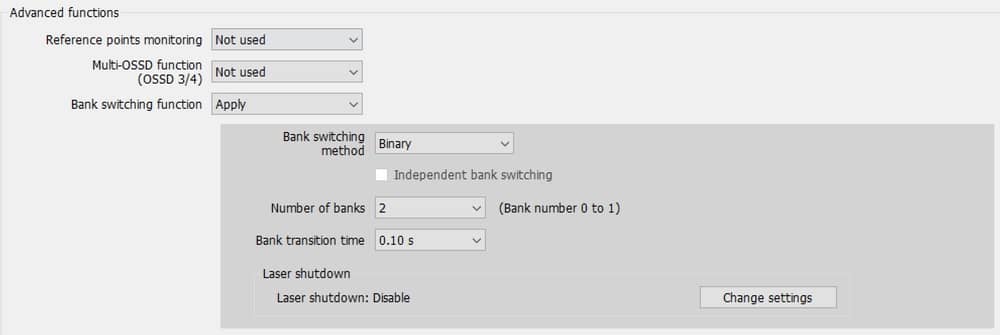

12. If the Bank Switching function is required and you have already purchased the optional cable (CE-CA-067-5000) that enables the functionality, enable this function in the Advanced functions section. Note that Muting and Bank Switching functions cannot be enabled at the same time.

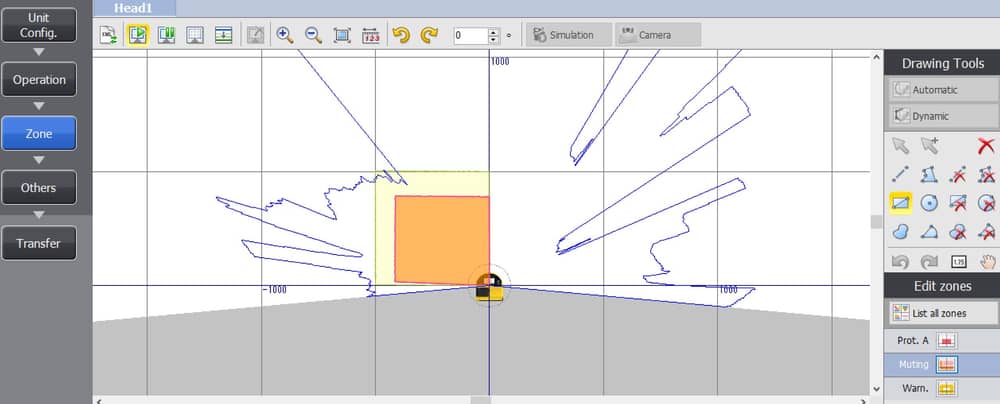

13. In the Setting menu, select Zone to configure the safety zone of the scanner

14. Draw the desired protection and warning zones using the Drawing Tools menu in the right side of the screen. If the Muting function is enabled, the muting zone should also be configured in this step using the tools on the right side menu

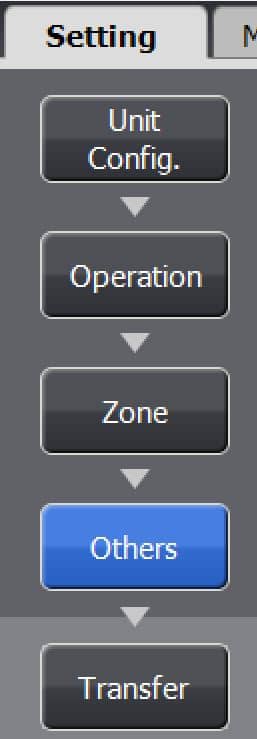

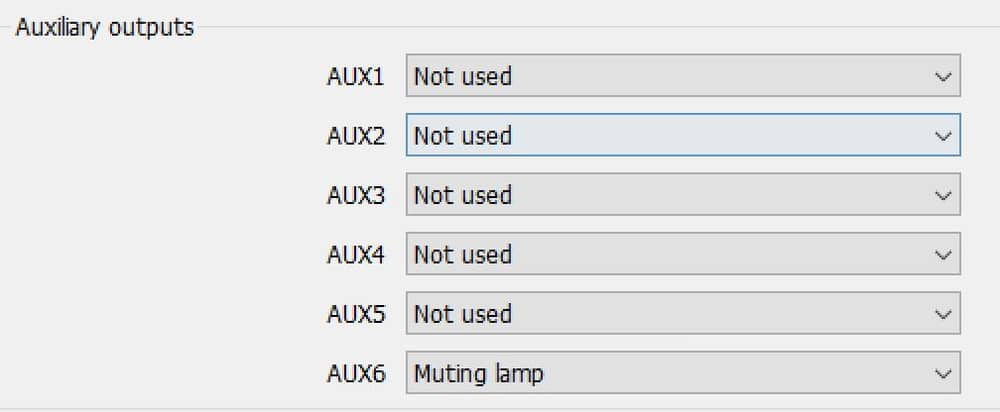

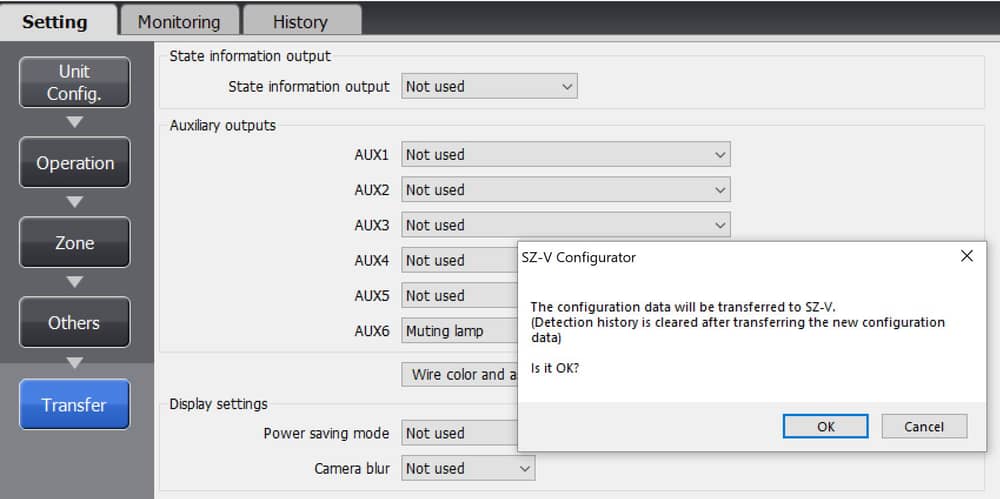

15. Once completed click on the Setting menu, select Others

16. If the Muting function is available and enabled, AUX6 should be set as a Muting lamp output in the Auxiliary outputs section otherwise, keep all selections as Not used

17. Next, click on Transfer as shown below

18. Click OK

19. Enter your new Password. (The default password is set to 1111)

20. Click OK

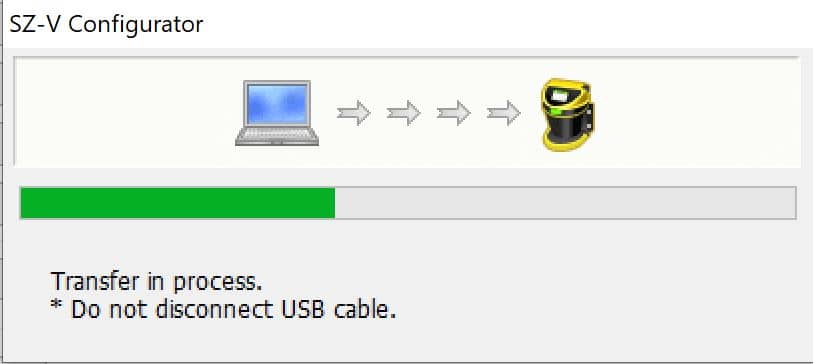

21. The configurator software will load the new configuration file onto your connected laser scanner

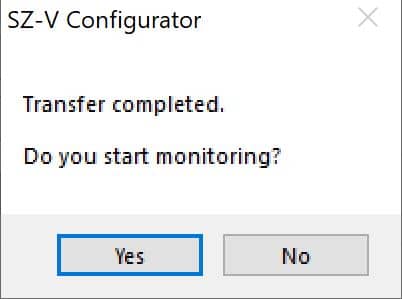

22. Select OK and Accept the configuration data

23. When the configuration file transfer is completed, select Yes to start monitoring

Keyence GL-R 745mm, 1465mm & 1900mm Light Curtains

Description

The Keyence Light Curtain (GL-R ) is an essential tool to ensure safety in the workplace. It can be used in multiple orientations to monitor large areas while remaining discreet and unobstructive. It will stop a machine if any undesired person or object crosses its safety zone. Muting is also available with the purchase of the Safety Module Muting Kit (CE-AP-002-0000). In order to use the Light Curtain with MachineMotion2, a Safety Module (CE-SA-008-0000__3) is required, please refer to the safety installation guideline section for the wiring. The Light Curtain specifications are as follows:

- Detection capability: ø25 mm

- Beam axis spacing/Lens diameter: 20 mm / ø5

- Detecting distance: 0.2 to 15 m

- Effective aperture angle: Max. ±2.5° (When operating distance is 3 m or more)

- Total/partial dynamic muting optional kit available (CE-AP-002-0000).

Getting Started

- Choose an appropriate position for the light curtain, and mount both the emitter and the receiver with the connectors pointing in the same direction using the two included mounting brackets (GL-RB02).

- The light curtain should be carefully positioned to provide the necessary protection. Access to the dangerous area must only be possible by passing through the light curtain safety zone.

- Configuring Keyence Light Curtains is not needed when using the provided cables (2x CE-SA-119-0001 and CE-SA-118-0001).

Safety Installation guidelines

According to safety guidelines, a light curtain barrier should have a maximum gap of 180 mm from the bottom and a minimum height of 1400 mm when there are no height restrictions.

The same safety guidelines apply for a laser scanner mounted vertically (i.e. monitoring the vertical plane).

Muting

The muting function automatically deactivates the safety status of the whole safety area (total muting) or part of it (partial muting). This feature is particularly suitable when an object, but not a person, has to pass through the dangerous area. This feature also allows carrying out cyclical operations without blocking a working machine.

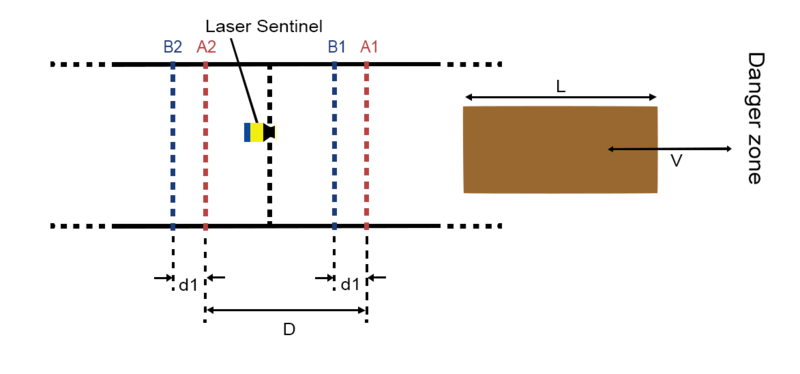

Muting sensors must be placed according to the material’s length and speed so they can recognize passing objects (such as pallets, vehicles, etc). Generally, two muting sensors are used, and they must be triggered sequentially. It is also possible to use four muting sensors (where sensors A1 and A2 are connected together and B1 and B2 are connected together).

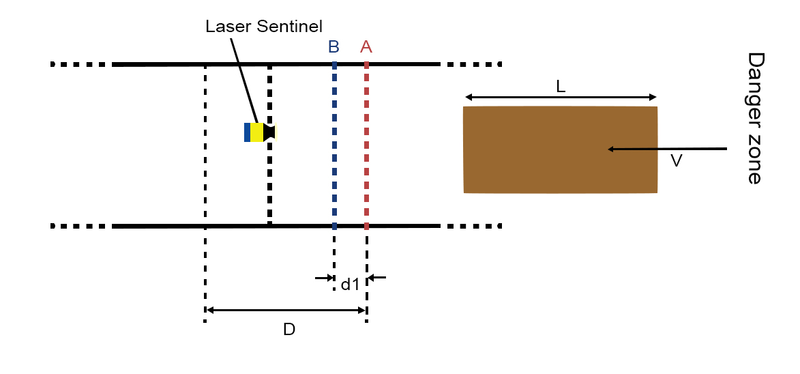

Unidirectional muting is used for objects entering or leaving an area. It requires two sensors, spaced at a distance slightly less than the length of the moving object, in order to detect undesirable objects with different dimensions or orientations.

Bidirectional muting is used for objects entering and leaving an area. In this case, four sensors must be used: two on one side of the safe zone (A1 and B1), and two on the other side (A2 and B2). Sensors A1 and A2 are connected together, and B1 and B2 are connected together. They should be spaced at a distance where two consecutive sensors are always triggered throughout the movement of the object across the safety zone.

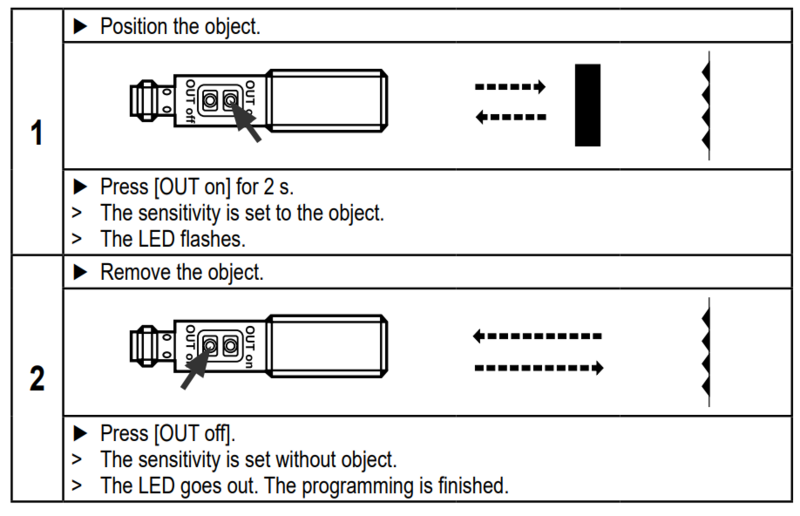

PNP Sensor Muting Configuration

When muting with Vention Muting kit (CE-AP-002-0000), please use the procedure below to configure the PNP sensors.

Muting for Laser Scanner

The Laser Scanner can perform both unidirectional and bidirectional muting.

In unidirectional muting, the “m” coefficient must be defined. This coefficient controls how long the safety zone remains off before reactivating. In other words, it defines the activation time delay following a muting event.

The “m” coefficient is a multiple of the real delay between Muting 1 and Muting 2 (T12). The range of this coefficient is an integer between 2 and 16 inclusive.

Note: When muting is triggered, all defined muting zones in the active zone set configuration will be muted

Muting for Light Curtain

The Light Curtains can only perform bidirectional muting, which requires four sensors. Once muting is activated, the entire safety zone will be muted (total muting). Partial muting cannot be used with the Light Curtains.