Rapid Series Palletizer

Contents

General Description

The Vention Rapid Series Palletizers are designed to optimize the palletizing process with a standardized, cost-effective design. From product selection to deployment, our field-proven solution ensures rapid operation and a quick return on investment. Tested extensively for minimal risk, our palletizers offer a savvy, turnkey approach for efficient results at every step.

Available Configurations

Below are the different cobots supported with their maximum payload and cycle times:

Vention’s technical team will assess all your box sizes and pallet patterns and validate which configuration is the right one for each application.

Inclusions & Options

Vention’s Rapid Series Palletizer comes with:

- Base with robot and gripper as well as pallet locators

- Safety components (when safety option is selected)

- MachineApps Palletizer Software

- Turnkey service: On-site deployment

- 3 SKUs programmed by Vention

- A 1 hour training session with our palletizer experts

- Remote Support Subscription (first year included)

Additionally, it is possible to add the following accessories and software upgrades for an additional cost:

- Conveyors (belts or rollers)

- Slip sheet dispensers

- MachineAnalytics

- Remote View

Design

Components Overview

General Technical Specifications

| Specification | Value |

|---|---|

| Air consumption | 12 SCFM* |

| Optimal input pressure | 5.5 bar* |

| Permitted pressure range | 4.5 - 7.0 bar* |

| Maximum pallet dimensions | 48 x 48 inches |

| Voltage (MachineMotion) | 100-240 V AC |

| Voltage (Robot) | 100-240 V AC |

| Total current | 15 amps |

| Operating temperature range | 10 -40 °C |

| Maximum operating humidity | 85% |

Note:* The exact values depend on the selected gripper.

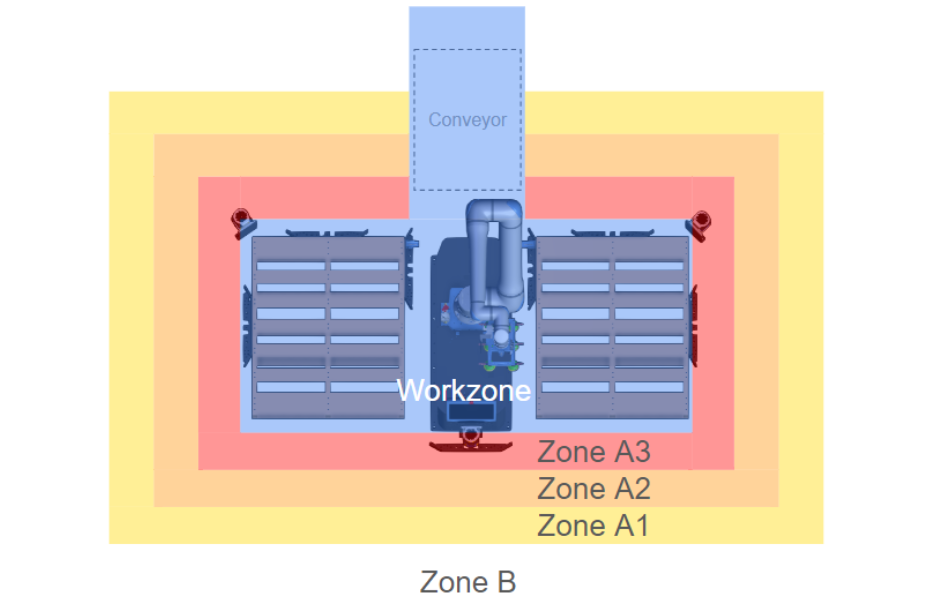

Safety Zones when Using Area Scanners

There are 3 area scanners (Vention Laser Area Scanner PR-DA-001-0489):

- Robot Workspace: the zone where the robot is limited to operate via a safety-rated zone limitation. Not monitored by an external safety system.

- Zone A: the protective separation distance zone that is monitored by the three area scanners. It reduces the speed of the robot and activates its collision detection. This zone is separated in 3 subsections: A1, A2 and A3.

- Zone B: the normal operation zone in which the robot operates at full speed and without any collision detection capabilities activated.

In order to automatically reset the safety system, the operator has to follow a predefined reset sequence (B-A1-A2-A3-A2-A1-B or B-A1-A2-A1-B or B-A1-B) and the sensors must detect the operator transitioning from one zone to the other in that specific order.

After an E-stop or if the operator goes in the workzone, the ability to auto-reset is deactivated and the palletizer needs a physical reset.

The operator needs to reset the safety by pressing the physical reset button located under the Vention pendant and then exit Zone A by following one of the predefined reset sequences (A3-A2-A1-B or A2-A1-B or A1-B).

The following equation applies in the case of fenceless cobot palletizer with area scanners.

S = K x T + C

S = Minimum safety distance in mm (Zone A) = 2050mm

K = Approach speed = 1600 mm/s

T = Stopping time = 0.582 s (cobot : 500ms / Slave area scanner : 82 ms)0.5)

C = Penetration distance = 1120mm (considering a distance of the area scanners from ground of 300mm)

In order to define the different zones, divide S in 3 equal zones. Zone A1 = Zone A2 = Zone A3 = S/3

Installation

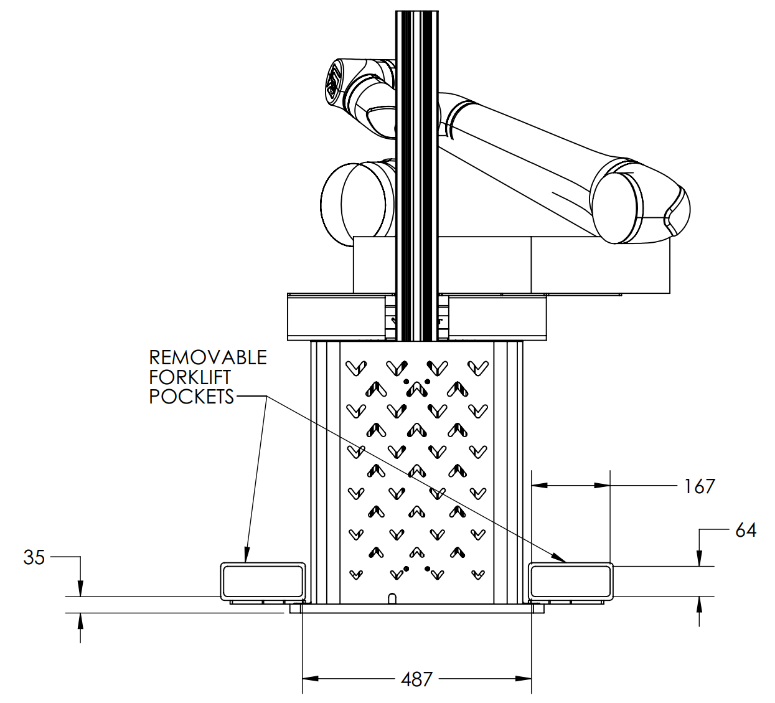

Lifting

In order to move and install Vention’s Rapid Series Palletizer, a forklift is required. Use the included forklift pockets to safely lift the unit into place. It is not recommended to lift using lifting straps due to the high center of gravity of the machine. The exact location of the CG depends on the type of robot arm and size of mounting column.

The forklift pockets can be removed after use to facilitate placement of pallet stops. Each pocket has 2x M8 fasteners that can be removed with a 6 mm hex Allen key.

Placement

Place the base in the correct position relative to the future location of the pallets. It is recommended to lay out the palletizer base, pallet stops and pallets before drilling anchors. Place the pallet locators based on the reach study conducted for your boxes. Anchor the pallet locators in place.

The precise location of the pallet locatots will be provided depending on your specific setup but in order to clear the robot shoulder, the minimum distance between the center the base and the pallet locators is as follows:

| Rapid Series Palletizer Configuration | Distance between Center of Base and Pallet Locator |

|---|---|

| UR10e on a Fixed or Telescopic Base | 283 mm |

| UR20 on a Fixed or Telescopic Base | 373 mm |

| CRX-25iA on a Fixed or Telescopic Base | 440.5 mm |

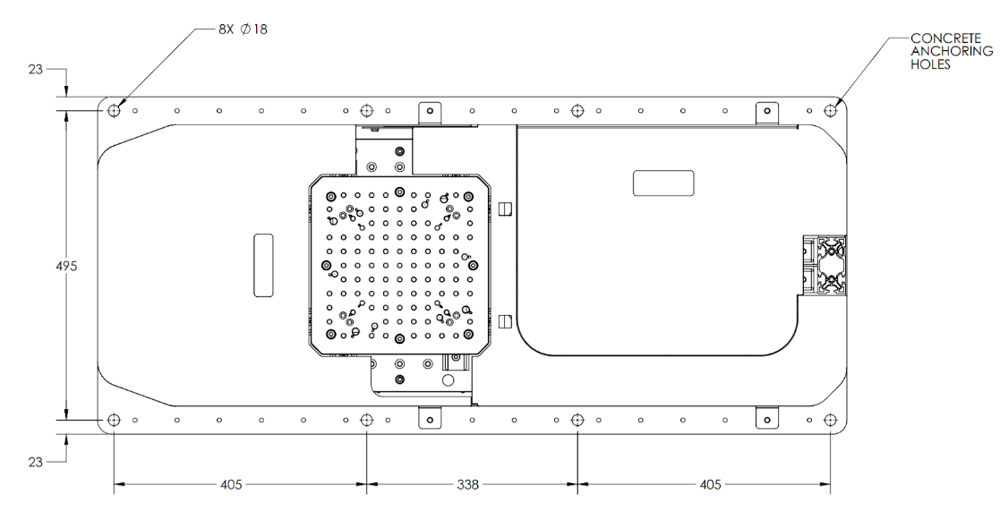

Anchoring

Rapid Series Palletizers must be anchored to the floor before operation. This removes the risk of tipping over under high loads. A proper concrete analysis must be done at each site of installation in order to determine the quality and depth of concrete. Failure to do so can result in failure of the concrete mounting screws. Space for eight ½ inch anchors is provided in the base.

It should be possible to drill through the mounting holes, should the drill bit be too large, the locations of each hole can be marked and drilled with the plate removed from the area.