Cost-savings during a manufacturing recession

According to Reuters and the Institute for Supply Management (ISM), the manufacturing industry entered into a recession in early 2023. The ISM reported the purchasing managers’ index slipped to the 16th percentile, the composite index fell to its lowest since the first wave of the pandemic, and the overall inflow of new business is lower - all unambiguously suggesting the manufacturing industry is in a recession. In the past, manufacturers adjusted to lower demand by right-sizing their workforce, but difficulties in combating labor shortages are making manufacturers reluctant to reduce headcount. The result? Cost reduction will have to come from elsewhere.

Creating an Advanced Manufacturing Team with MAP

Today, industrial automation is becoming the primary solution to reduce costs, while still solving the prevalent labor shortage. But recent innovations in automation technology are enabling some manufacturers to take it one step further: creating their own Advanced Manufacturing Team to drive the industrial automation roadmap across their manufacturing plants. The emergence of such a team was made possible by the do-it-yourself movement that resulted from the democratization and platforming of industrial automation technologies. Resources such as user forums and e-commerce websites, alongside easier-to-use industrial automation components, are helping manufacturers gain automation expertise. But one-stop-shop Manufacturing Automation Platforms (MAP) are about to help even more.

Becoming the de-facto software and hardware platform for Advanced Manufacturing Teams, MAP allows for all the steps of an industrial automation project, from ideation and design to procurement and deployment, to take place in a unified, easy-to-use digital environment. Component-based 3D design, low-code/no-code programming, online ordering with fast shipping, plug-and-play assembly, and software-assisted deployment are a subset of the features that MAP provides out-of-box. The significant speed and ease of use provided by such a platform (vs. the traditional way to realize industrial automation projects), enables any manufacturing professional to be at the forefront of their company’s industrial automation agenda. In other words, hardly recruited labor can be reallocated to advancing automation projects.

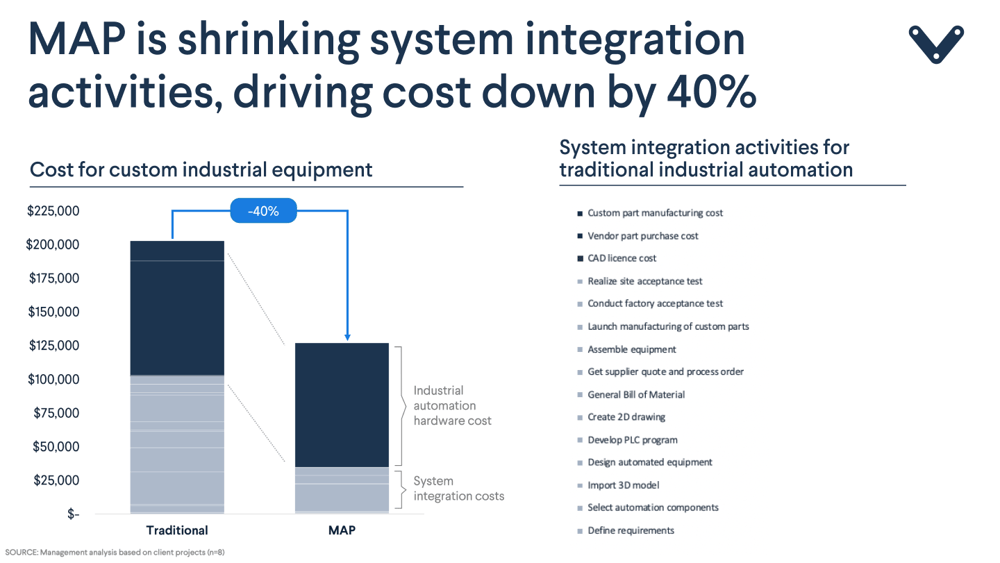

But there is more. According to our clients’ own analysis, leveraging Vention’s MAP enables them to execute automation projects in a self-serve manner (with expert guidance throughout) and shortens their project time estimate by up to 3x vs. their usual approach to industrial automation. This results in a 40% reduction in automation investment, a significant amount considering the lingering recession.

For manufacturers looking to reduce costs, building an Advanced Manufacturing Team within the company is a great place to start. With the do-it-yourself capabilities MAP provides, this team will not only realize the cost and productivity gains of industrial automation, but it will do it faster and with significantly less investment.