Conveyors are one of the most popular material handling applications. Vention’s modular approach to conveyors provides maximum simplicity and versatility. Customize and combine roller or belt conveyor modules, a MachineMotion controller, and motors into one easy-to-use system. Program your conveyor sequence with MachineLogic and deploy it in minutes.

With Vention, experience unique benefits

- Quick payback: See ROI in nine months or less allowing you to accelerate your automation roadmap.

- Easy to assemble: Assemble your full conveying solution in as little as four to eight hours.

- Fast delivery: Receive your order in three to seven days to start automating faster.

- Customizable: Configure your conveying solution using our library of modular components to future-proof operations.

The five most common conveyor configurations

Roller conveyors are best for heavy loads where less precision is required, like moving boxes. Belt conveyors, on the other hand, are best for pick & place movements that require precisely locating smaller or irregularly shaped objects. Visit Vention’s Resource Center for in-depth information about roller and belt conveyor modules.

Keep reading to find out the five most common applications for roller and belt conveyors.

O-ring belt conveyor

O-ring belt conveyors use motors and sensors to control the movement of products. They are ideal for light-duty manufacturing and packaging applications. The o-ring belt conveyor comes in modular conveyor segments in increments of five rollers, is suitable for small payload items, is low cost, and has a no pinch point design.

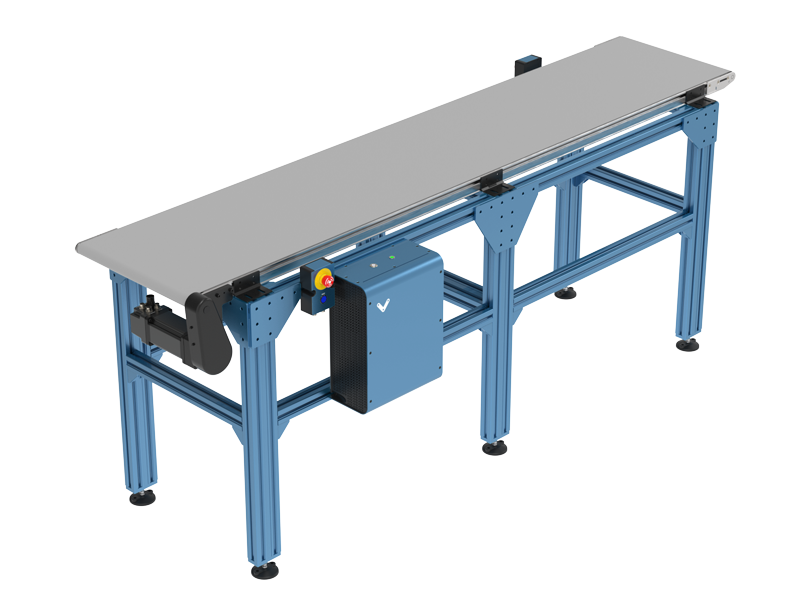

Belt conveyor

Belt conveyors, an alternative to discrete rollers, provide better grip making them ideal for operations requiring a slight incline or decline. Belt conveyors fully support the product and can be used for indexing. They are also easy to install, suitable for small items, allow for repeatable positioning, and offer better adherence support.

Heavy-duty conveyor

Heavy-duty conveyors, capable of moving up to 360 kg depending on the roller configuration, are the ideal solution when moving packages or large items without a pallet. You can transport items directly on the rollers, add sensors, and program code-free using MachineLogic, and it comes in modular conveyor segments in increments of five rollers.

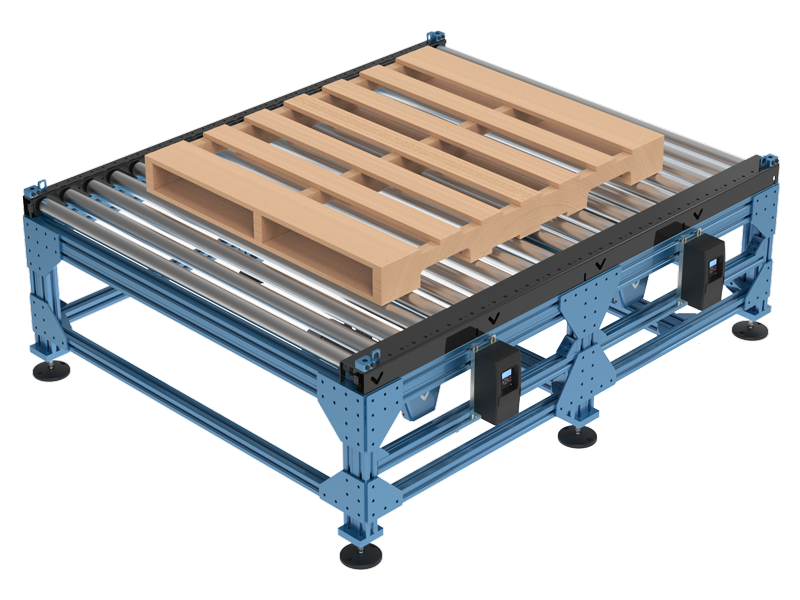

Heavy-duty pallet conveyor

Heavy-duty pallet conveyors, capable of moving up to 500 kg payloads depending on pallet configuration, are the ideal solution for operations requiring a pallet.

Timing belt conveyor

Timing belt conveyors, an alternative for larger products, provide flexibility with the availability of multiple lengths and the option to customize the spacing and number between each belt.

Support from design to deployment

Whether you prefer a complete turn-key package or specific hardware kits and components, we have you covered. We provide support at different levels based on your needs for every application you make with Vention. We offer free design help, on-site setup, and Remote Support whenever you need it.

Questions? Interested in a conveyor solution for your manufacturing floor?

Vention’s team of automation experts is available to help you find the correct conveyor configuration for your specific needs. Reach out today or start designing now in MachineBuilder.