A robotic palletizer is a machine that automatically stacks cases of goods onto pallets. Need to deploy one on your manufacturing floor? Here are our top five design considerations.

1. Define cell layout and dimensions

The layout of your palletizing cell will depend on the number of pallets it can accommodate as well as the position of the input conveyor.

Number of pallets

A single-pallet palletizer will take more time between cycles and will be easier to configure and program. A double palletizer has a greater holding capacity but takes more work to optimize.

Input position

As part of the layout, you will also need to decide where the “input conveyor” is located. The back of the cell is the most popular choice because it leaves more room to maneuver the pallets at the front of the cell.

In a double-pallet cell, another conveyor input option is at the midpoint between the two pallets. This setup minimizes the gantry system’s travel distance and provides the best throughput.

However, it is slightly more expensive due to the need for a longer linear axis and leaves less room to maneuver pallets within the cell.

2. Choose between a 3-axis palletizer and a 4-axis palletizer

3-axis palletizers

These are suitable for palletizing square-shaped boxes because the boxes don’t need to be rotated when being stacked in layers on the pallet. 3-axis palletizers are low cost and simple to program.

4-axis palletizers

4-axis palletizers are best for palletizing rectangular boxes. The palletizer rotates the boxes to stack them in multiple layers on the pallet, resulting in better stability. 4-axis palletizers are also more complicated. They require an indexer (a piece of the palletizer that rotates the boxes) at the end of the Z-axis to rotate the box from the initial position on the conveyor to the drop point on the pallet.

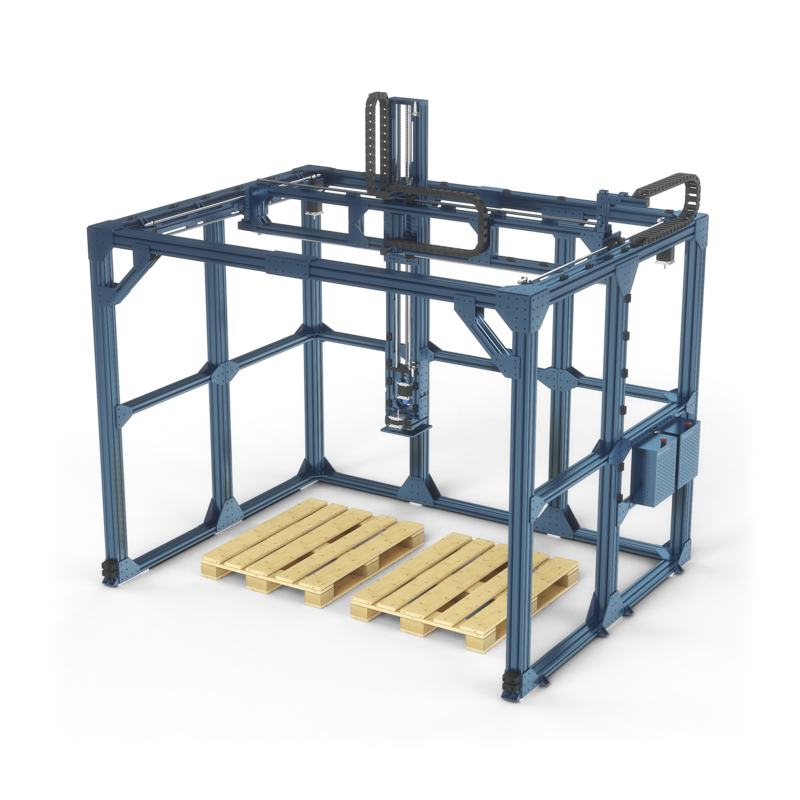

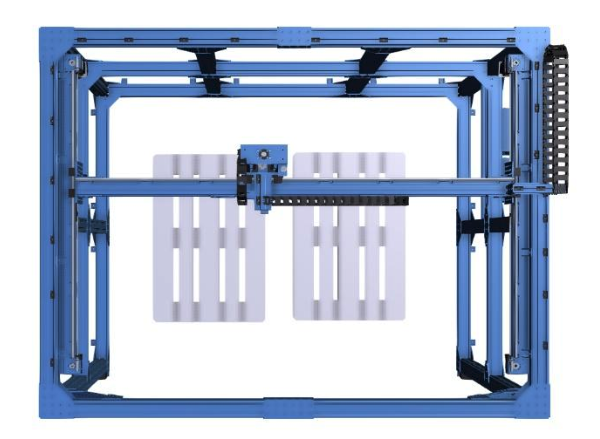

|

|---|

| Fig. 1: Example of a double palletizer. |

3. Choose a height-adjusting X-Y plane or a Z-axis column

Z-axis column palletizers

Most palletizer architectures are based on a single linear actuator driven by a ball screw or rack and pinion for the Z-axis column. Such architecture results in the Z-axis extending inside and outside of the palletizer’s top structure throughout the palletizing cycle.

Compared to X-Y palletizers, Z-axis palletizers are typically faster and require fewer moving parts. However, they also have a lower load capacity.

Height-adjusting X-Y plane palletizers

Also known as vertically moving X-Y plane palletizers, these have a double Z-axis by design. X-Y palletizers are great for low-ceilinged environments because the Z-axis does not extend past the palletizing cell dimensions. One drawback: X-Y palletizers have limited palletizing possibilities because the X-Y plane can easily collide with the boxes (as they begin to stack up) if the input box picking location is lower than the last layer of the pallet.

4. Implement safety measures

Palletizers, like any type of automated equipment, should be set up with safety in mind. It’s safest to have palletizers operate within a fenced enclosure.

If you choose to place the palletizer in an unfenced area, you should integrate further safety mechanisms. Never set up a palletizer in an unfenced area. If there is no fenced area on the shop floor (i.e., no enclosed room), you will have to add safety fencing to the palletizer cell’s structure. We recommend putting up enclosure panels made of polycarbonate or plastic-coated wire mesh. The machine itself should only be accessible via a safety-locked door in the fencing.

5. Define floor-mounting conditions

Palletizers are often floor-mounted, with a permanent anchor set in the concrete of the shop floor. This method is the most stable and reliable. However, palletizers can also be mounted on a wheel and moved to the required location for a more flexible shop floor layout. A mobile palletizer often uses a locating pin to maintain its working position.