Introducing MachineCloud. Vention’s latest addition to our Manufacturing Automation Platform (MAP)

MachineCloud is a one-of-a-kind deployment solution that enables users to deploy automation from the cloud to the factory floor in minutes. It uses software-assisted, step-by-step deployment instructions derived from its digital twin to ensure successful deployment each time. MachineCloud also includes remote machine monitoring and continuous development for simple re-deployment.

MachineCloud fits seamlessly within MAP as the fourth step to successful automation. To jumpstart your automation journey using MAP, start in MachineBuilder to design your machine in our intuitive CAD software, then switch to MachineLogic to create powerful code-free automation sequences. Once you are satisfied with your design and automation sequences, order your machine through MachinePortal, then deploy it from the cloud to your physical equipment in minutes with MachineCloud.

When you need to re-deploy your machine, simply modify your automation sequences in MachineLogic and push deployment through MachineCloud, resulting in the most simplified deployment and re-deployment solution on the market.

Learn about MachineCloud from Vention’s MachineCloud Product Manager, Ariane Dang:

Hardware setup & assembly

The first step of deployment with MachineCloud is hardware setup and assembly. Before beginning, you or your assembly team should ensure you received the correct tools and parts which are listed in your bill of materials. In the provided instructions, the assembly will be broken down into steps with both an exploded and completed view. Each component is identified, along with its corresponding fasteners. You will also find general information on how to begin assembly, along with some advanced tips.

It is highly encouraged to use MachineBuilder during assembly so you or your assembly team can view the design in 3D. Easily add your assembly team to your project as design collaborators or send them a private link. Within MachineBuilder, several key features support easy assembly: 1) tree view, 2) exploded view, 3) measurement tool, and 4) annotation tool.

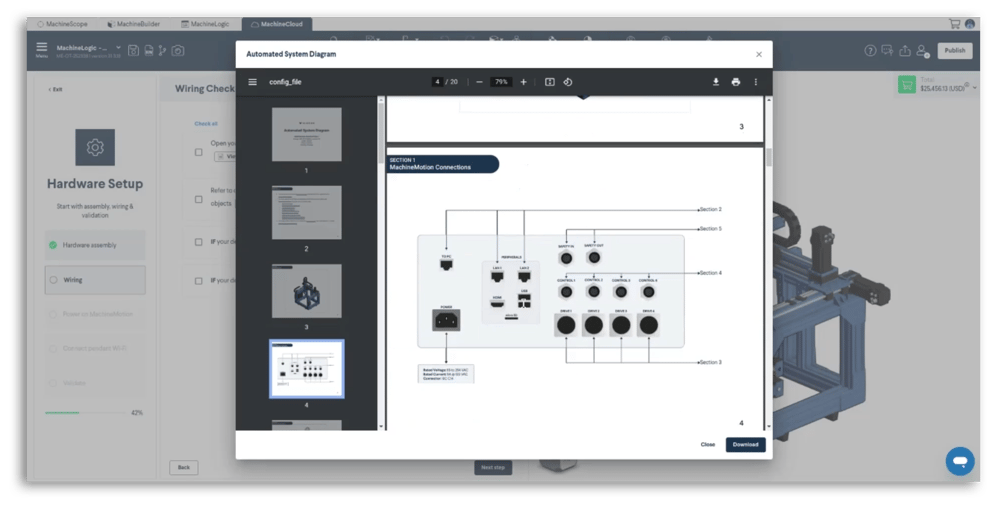

Once assembly is complete, you will be able to wire all of your cables by carefully following our intuitive Automated System Diagram, pictured below.

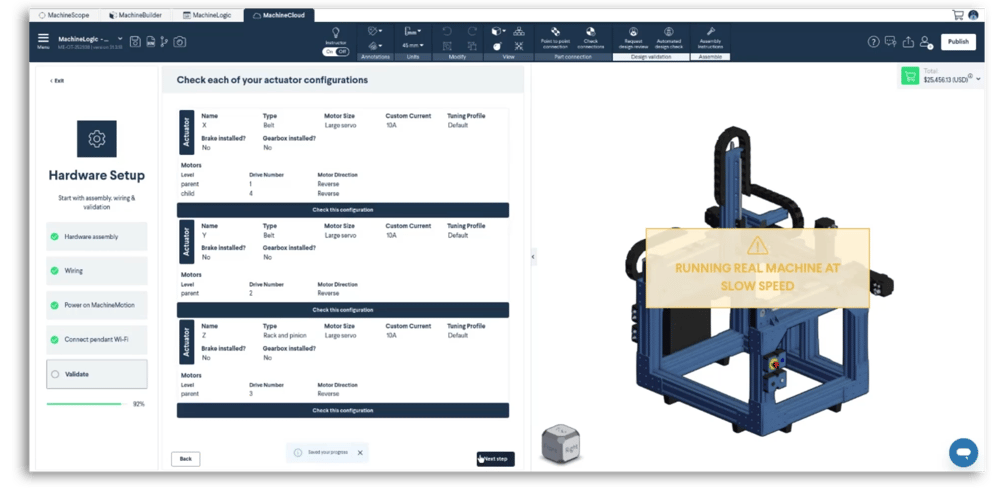

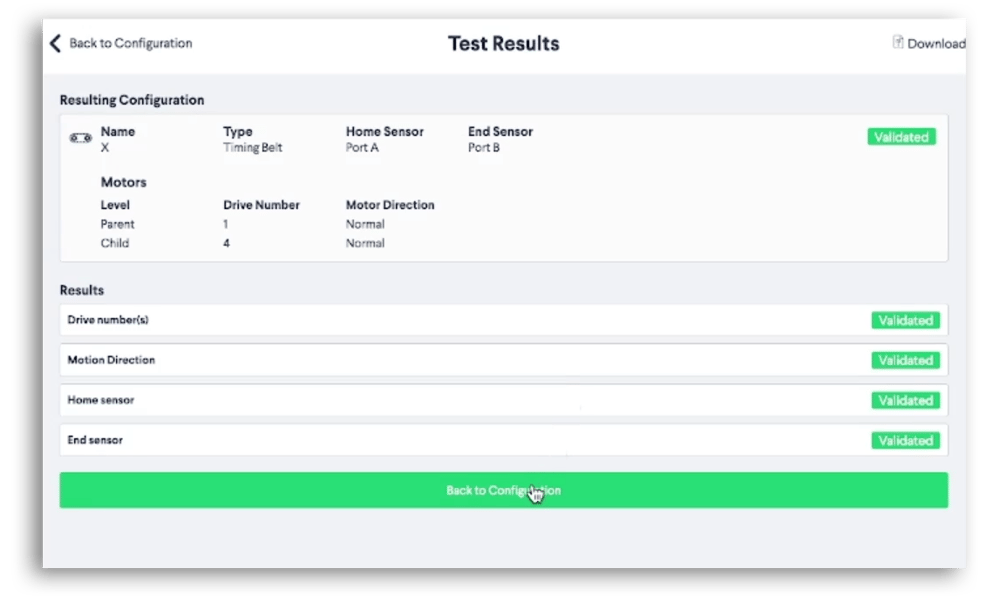

Next, you will be prompted to validate each of your actuator configurations. Confirm your motors are the correct size and that all the necessary brakes and gearboxes are installed.

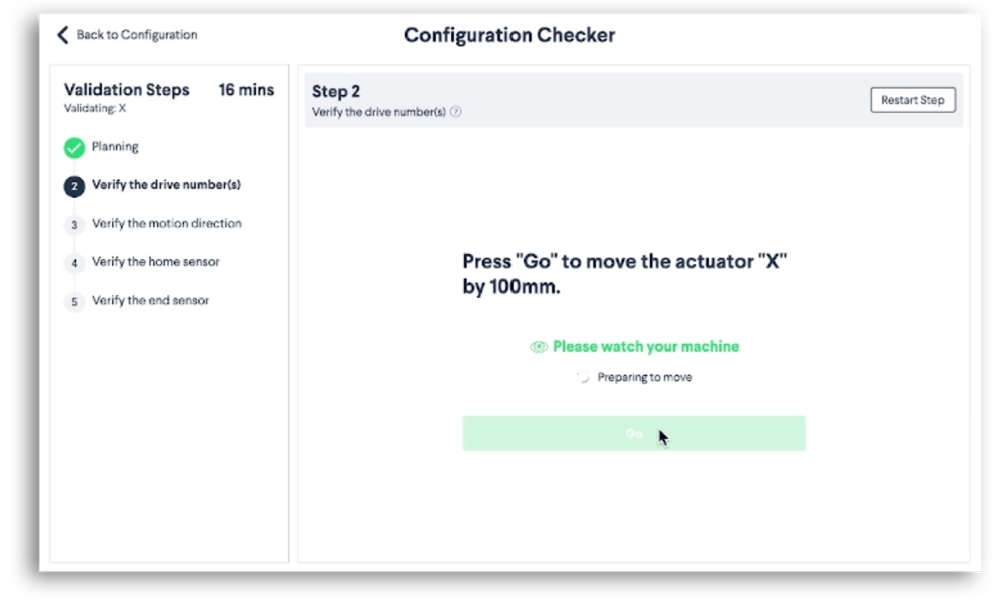

Once your actuator configurations are confirmed, use the Configuration Checker to be guided through a motor direction test which moves your physical machine at a slow speed to confirm the configurations are correct. You will also be asked to confirm your sensor’s positions. Results will be displayed once those tests are complete.

Software setup

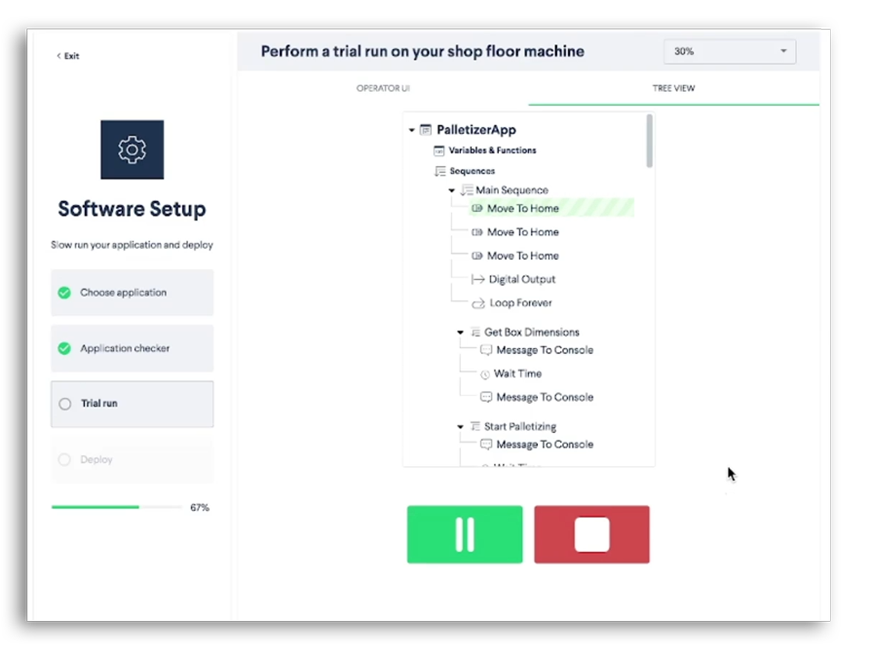

Once the hardware setup is complete, you will be prompted to begin the software setup. Within this step, choose the application you wish to deploy and use the Application Checker to verify that your program has no errors, such as missing initialization instructions or missing associated configurations for various commands.

Next, a trial run of your application will be performed on the physical machine at a slow speed to ensure it checks off all of your requirements. Once the trial run is complete and you are satisfied with the results, you can deploy your application directly to your machine within seconds.

Your application is now successfully deployed!

Continuous development

Once your application is deployed, easily make updates and improvements to your machine at any time in MachineLogic, then re-deploy through MachineCloud. With the newly raised ceiling of MachineLogic, you can now program more complete solutions using lambda functions to include multiple SKUs, variable dimensions, and complex calculations.

The future of automation deployment is MachineCloud

Begin designing your next automation project today or talk with one of our experts.