Workstations & Workbenches

Custom Workstations Built for Every Operation

Design workstations and workbenches that adapt to your operations. Fully customizable, rugged, and ready to ship next day.

Field-proven across industries

Machines in the Field

Factories Using Vention

Industries Served

Industrial Grade Workstations, Shipped Next Day

Designed for Every Task

From packing and assembly to inspection, ergonomic workstations improve efficiency, accuracy, and safety across your workflow.

Packing & Kitting

Streamline packing and kitting tasks to save time, reduce strain, and minimize mistakes.

Assembly

Support assembly with ergonomic and flexible workstations that boost efficiency and quality.

Inspection

Provide comfortable, well-lit workstations for precise inspection to catch defects early and ensure quality.

Define your initial frame

Select the core dimensions for a fast starting point. Click Generate CAD to open the model in MachineBuilder and customize every aspect of the workstation.

Building or Retrofitting Your Facility?

Our Lean manufacturing experts will help you scope, design, and commission complete fleets of workstations, flow racks, and carts on your timeline. No charge.

Modular Hardware Ecosystem

Plug-and-Play Hardware

Eliminate integration hassles with the largest library of modular automation components. Certified for plug-and-play compatibility.

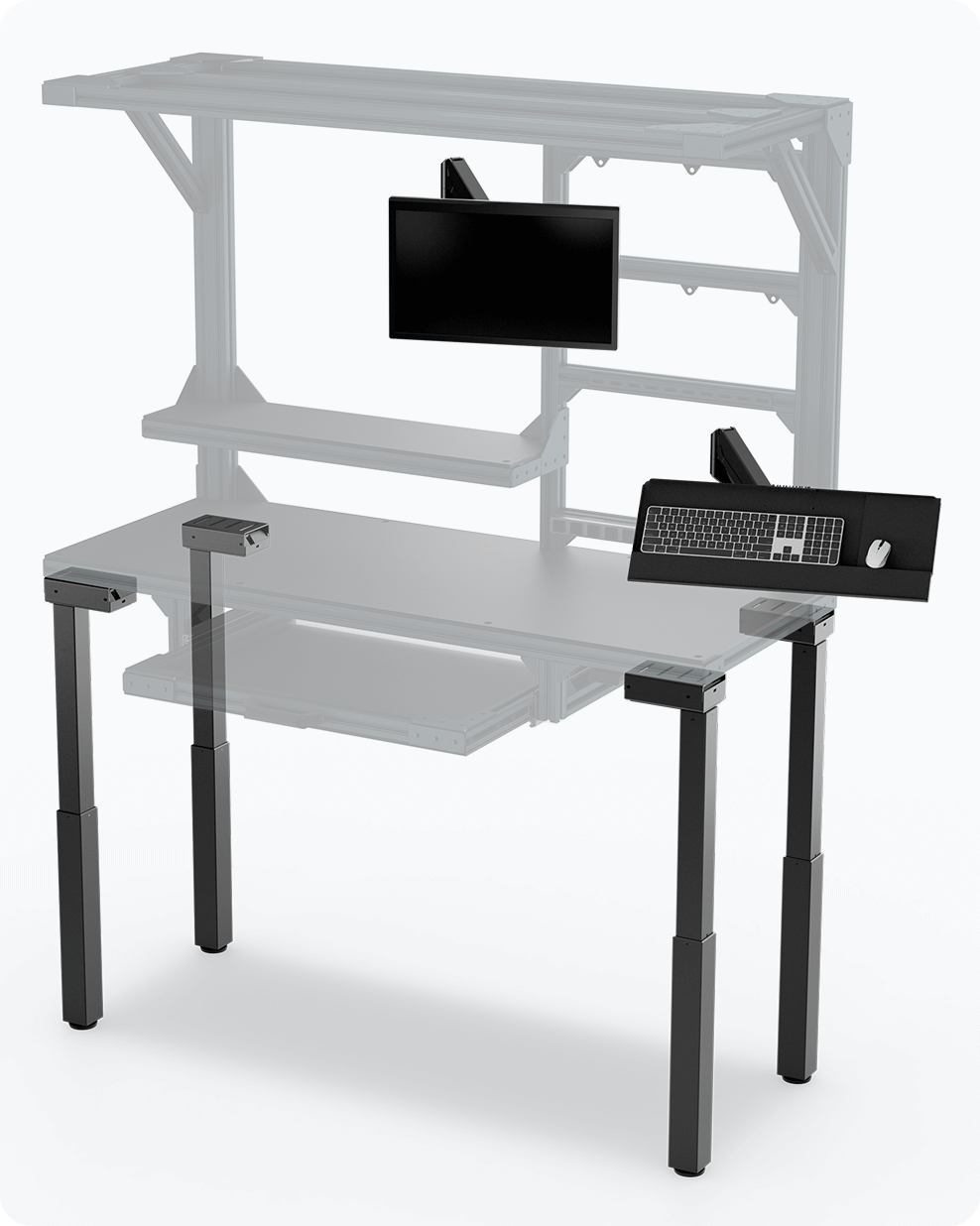

Ergonomics

Enhance workstation adjustability to reduce strain and prevent work-related injuries.

Telescopic leg: control height at the push of a button

Levelling foot: stabilize workstation

Monitor and keyboard arms: maintain proper posture

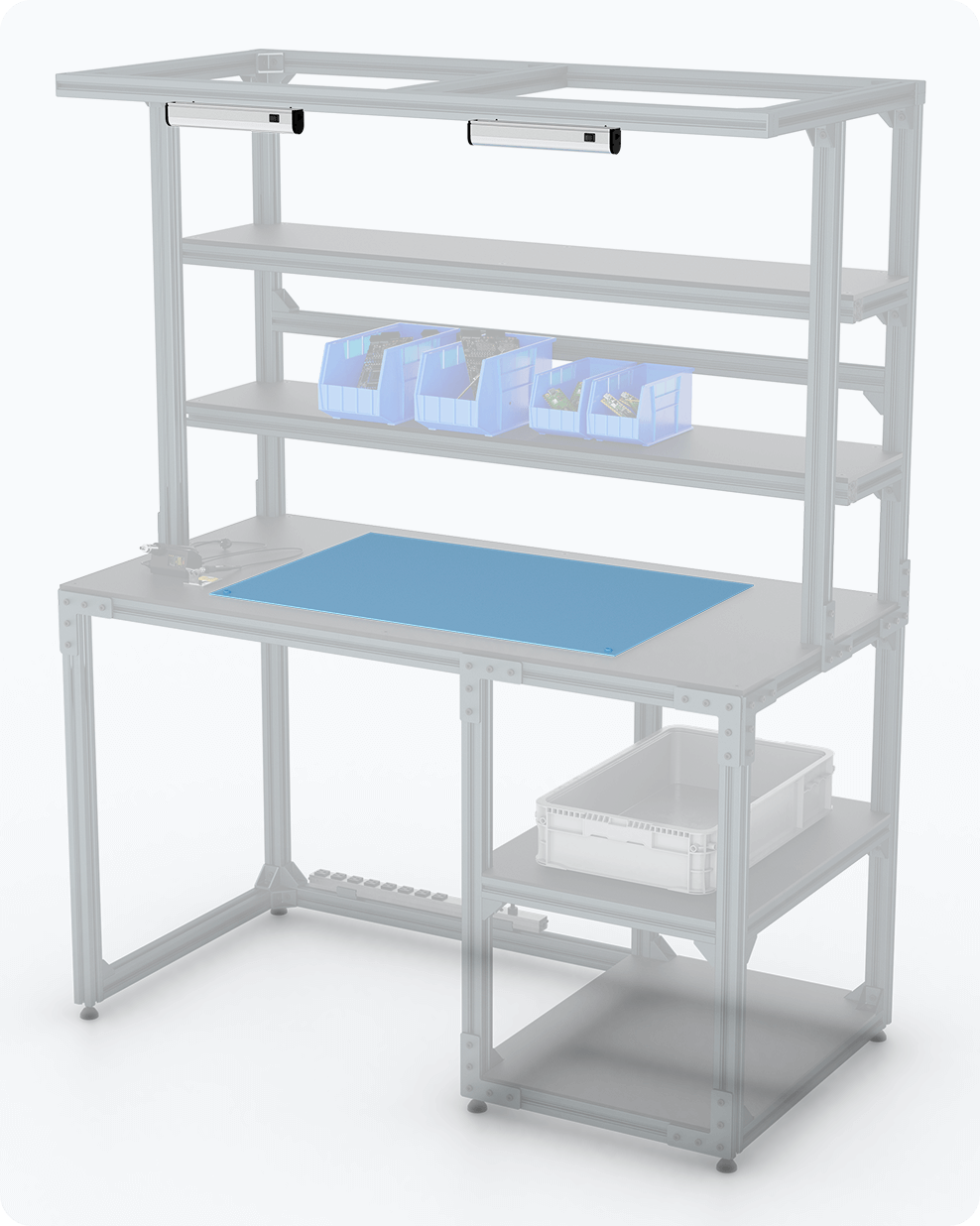

Organization

Keep tools and materials neatly arranged for a clutter-free, efficient workspace.

Drawer: secure storage for tools and supplies

Tools hanger and pegboard: keep items within reach

Cable management: keep cables neat and organized

Comfort & Safety

Maintain a comfortable workspace with proper airflow, effective lighting, and ESD protection.

Fan: maintain a cool, comfortable workspace

Lighting: overhead and task lights for a focused workspace

ESD kit: create a static-safe workspace

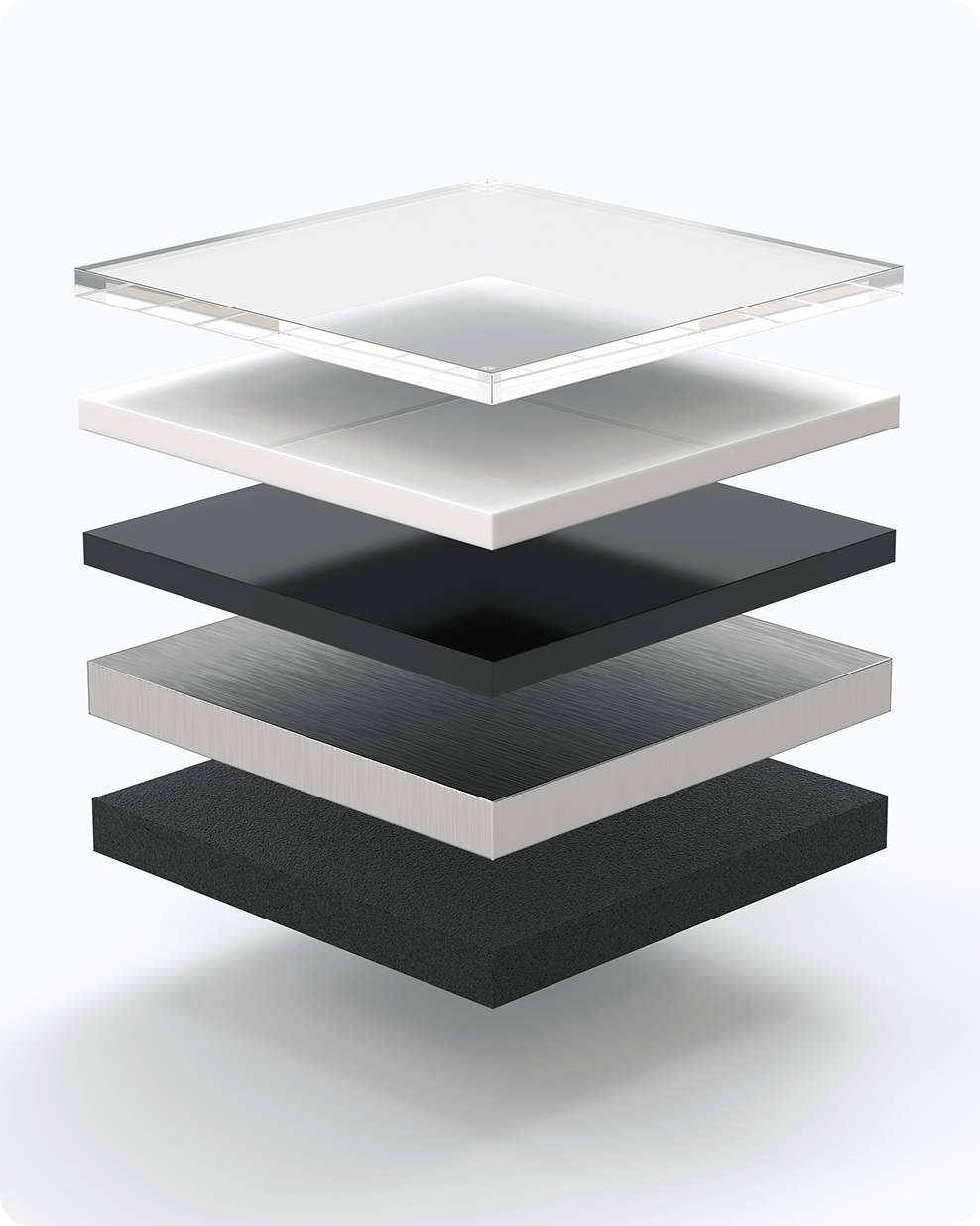

Panels & Table Tops

Create custom panels and tabletops from an extensive range of materials.

Choose from various materials and thicknesses

Customize cutouts to fit your design

Pre-cut panels with holes and all fasteners included

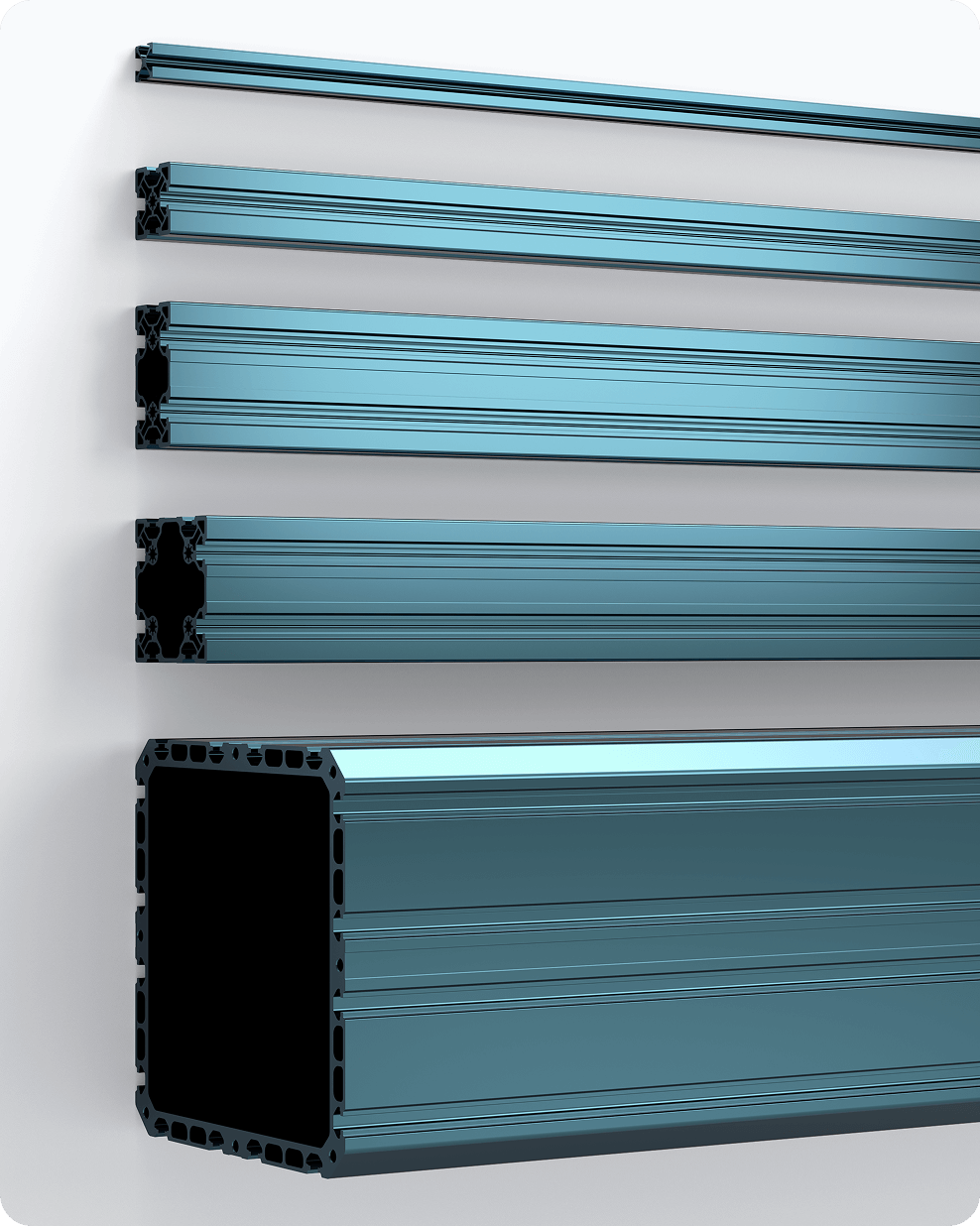

Extrusion Ecosystem

Build strong, versatile workstations with precision connectors and modular t-slot extrusions.

High-precision connectors with self-positioning locators

Patented extrusions for maximum strength and rigidity

Easy assembly with versatile configurations

Explore Workstation & Workbench Design Templates

Build Exactly What You Need

Access designs created by Vention experts that you can purchase as-is or customize to your needs, helping you launch projects in record time.

Get expert help designing your custom workstations and workbenches.

Customer Success

From Design to Deployment

Discover how teams used Vention to bring custom workstations and workbenches projects to life quickly and efficiently.

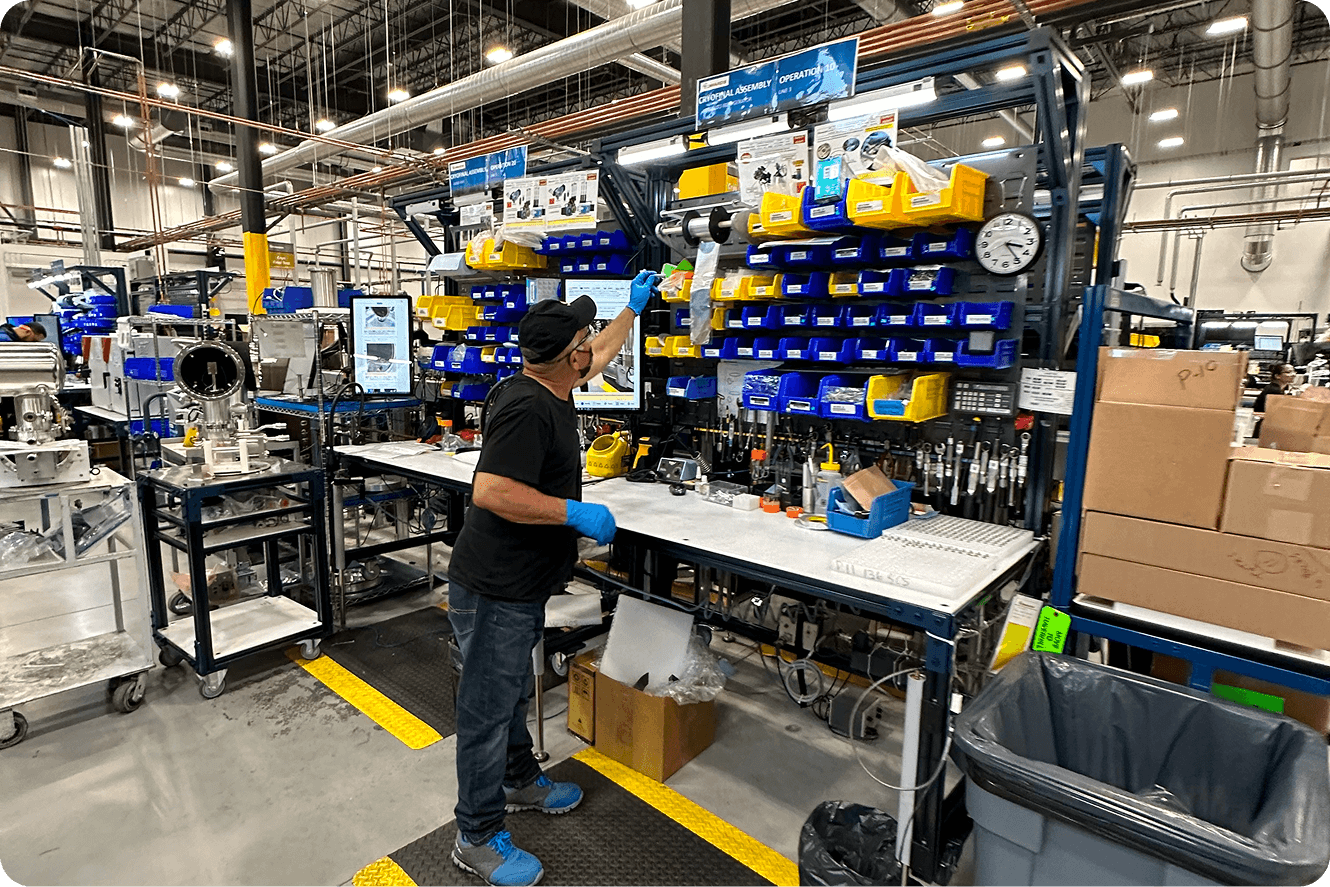

Edwards Vacuum Furnished a Full Factory in a Few Weeks

Introduced modular and ergonomic industrial equipment to create a safer working environment and improve productivity.

1-week from design to deployment

165+ workbenches, jigs & fixtures

50% factory expansion

Sears Seating Maximized Employee Ergonomics

Reduced OpEx by 20% and achieved ROI in just 15 months with a more efficient production line.

Deployed in 15 Days

15 months payback on automation

Creation of a reliable and repeatable design library

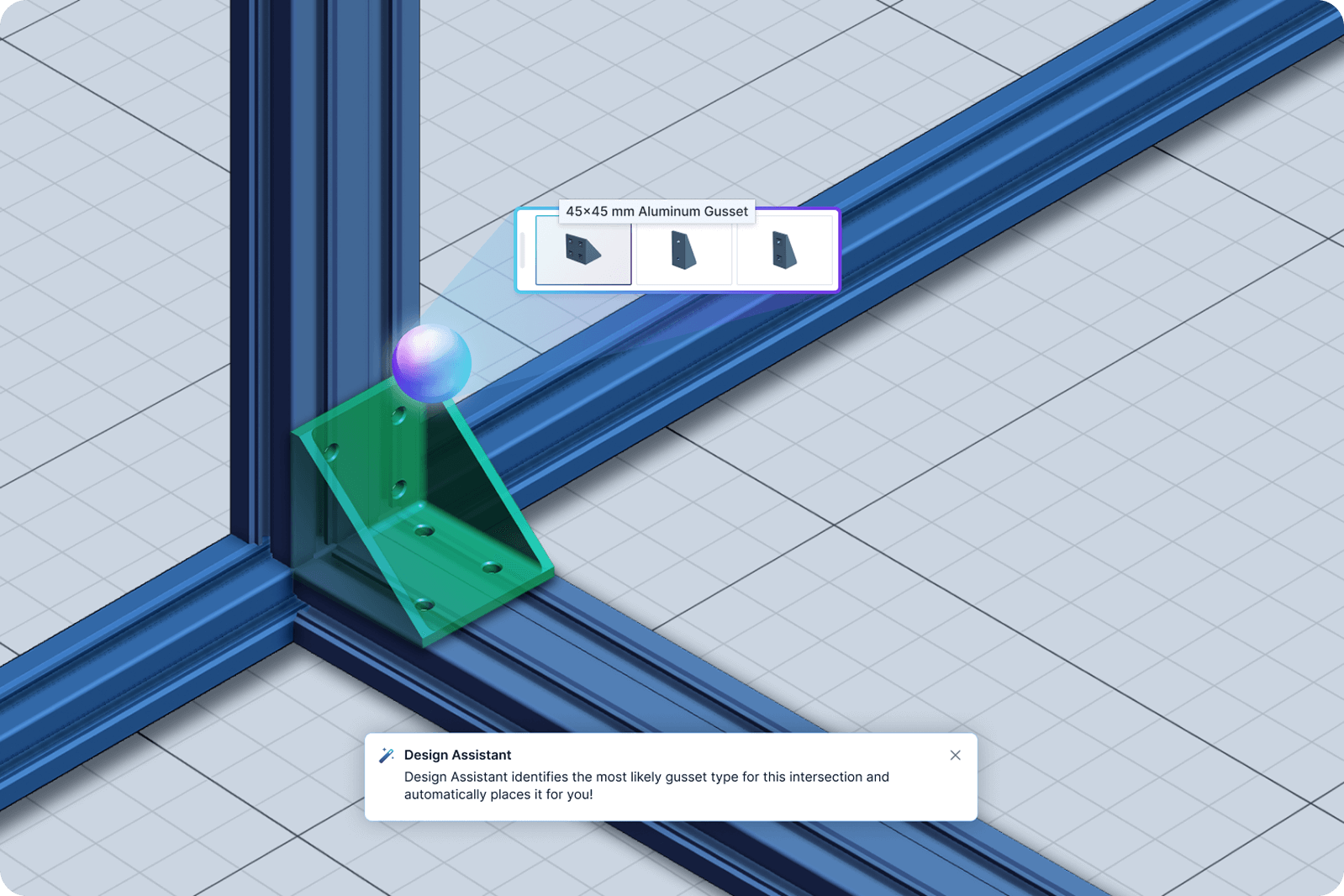

All-in-One AI-Powered Design Platform

From AI-powered design and team collaboration to fast ordering and easy assembly, MachineBuilder gives you the complete path from concept to build.

Design Smarter with AI-Powered CAD

Get AI-driven part recommendations and guidance, add connectors with intelligent auto-complete, and validate instantly using the smart design checker.

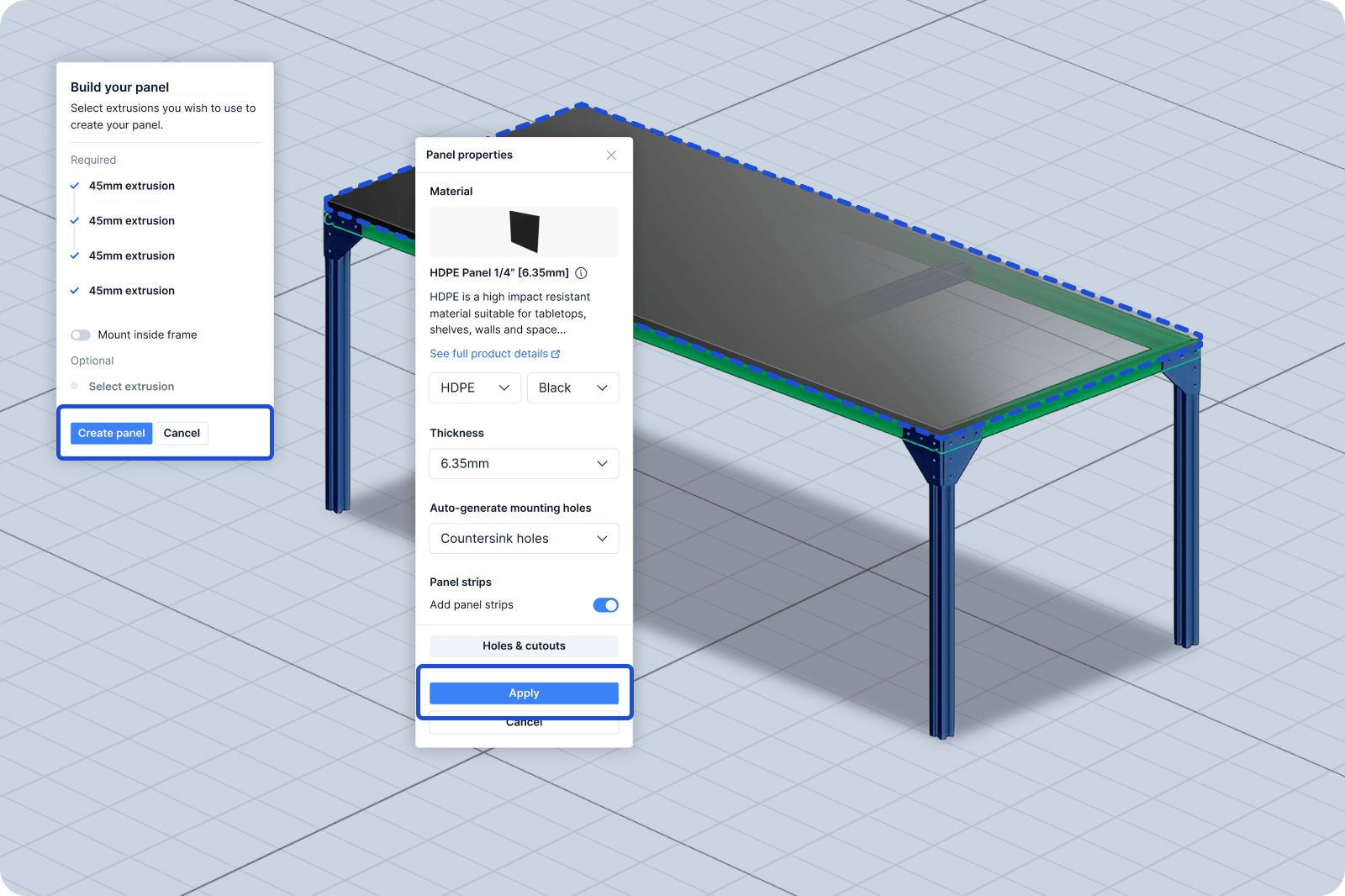

Generate Precision-Cut Custom Panels

Create fully customized panels with Panel Studio, choosing from a wide selection of materials and adding precision cutouts to fit your designs perfectly.

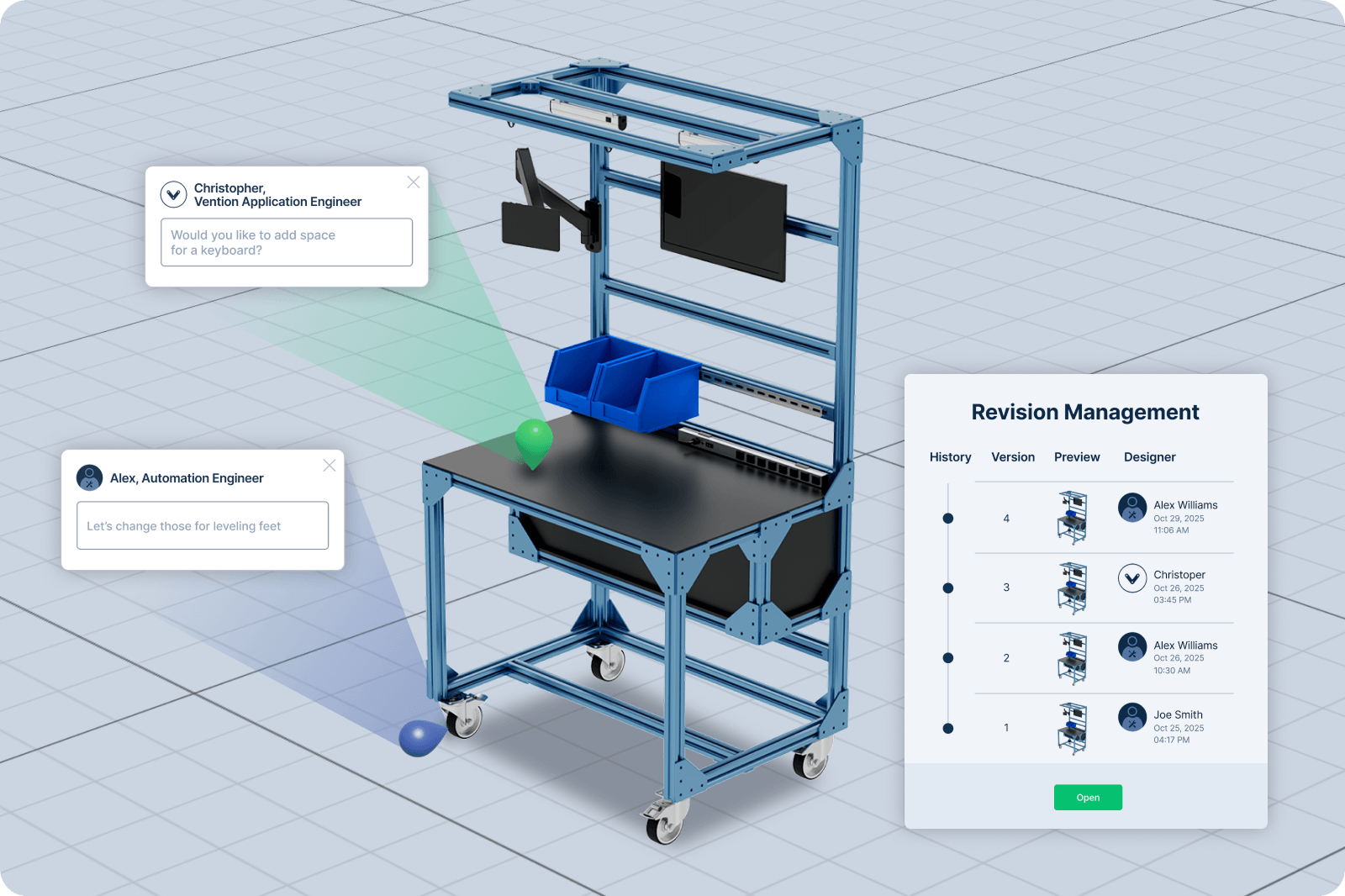

Collaborate with Your Team in Real Time

Comment, share, and review designs with your team, manage revisions with branch-based version control, and control access to collaborate seamlessly with colleagues.

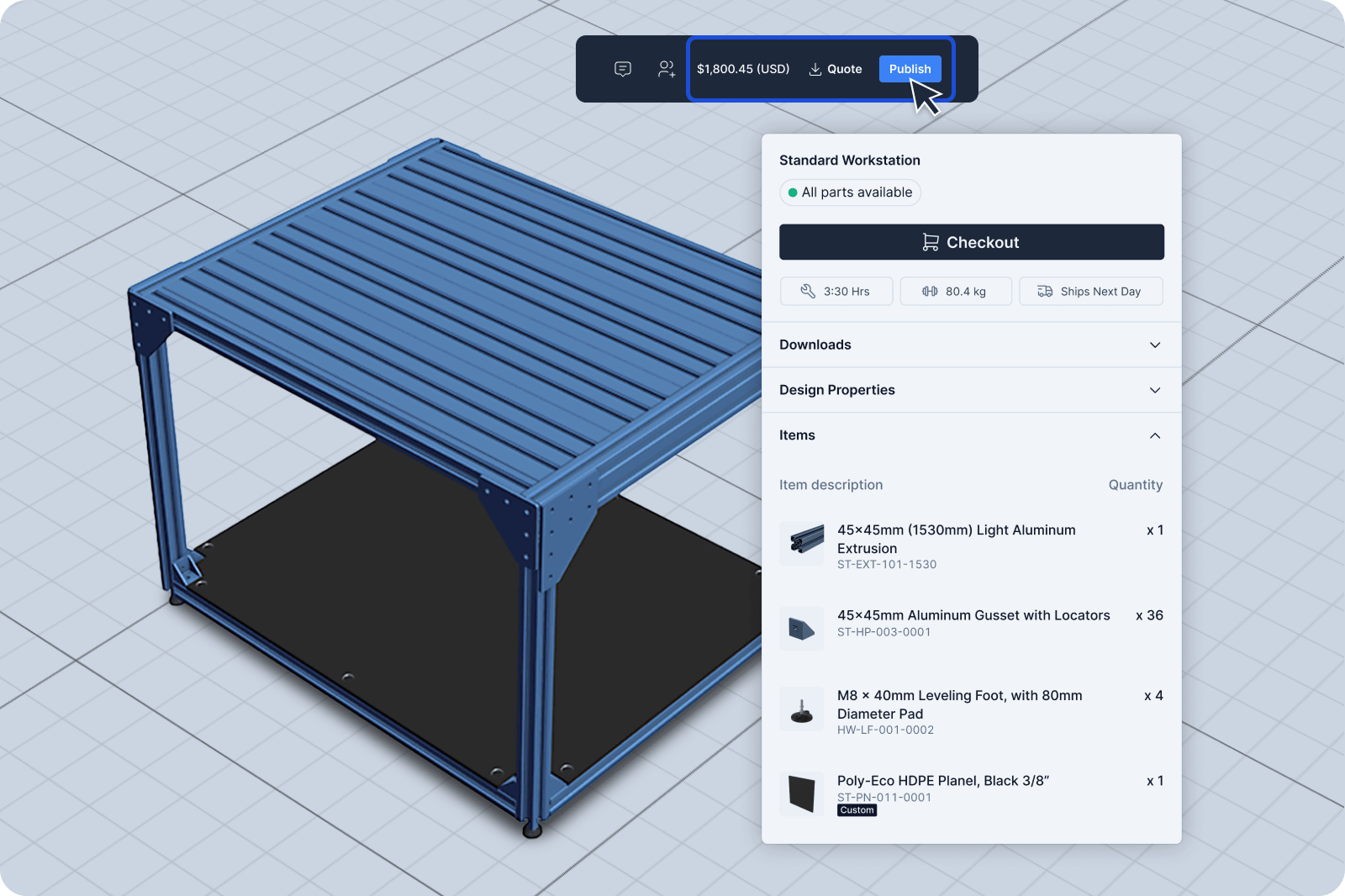

Get Instant Design Pricing

See pricing update instantly as you build your design for full transparency, easily generate quotes, and download a complete BOM with just a few clicks.

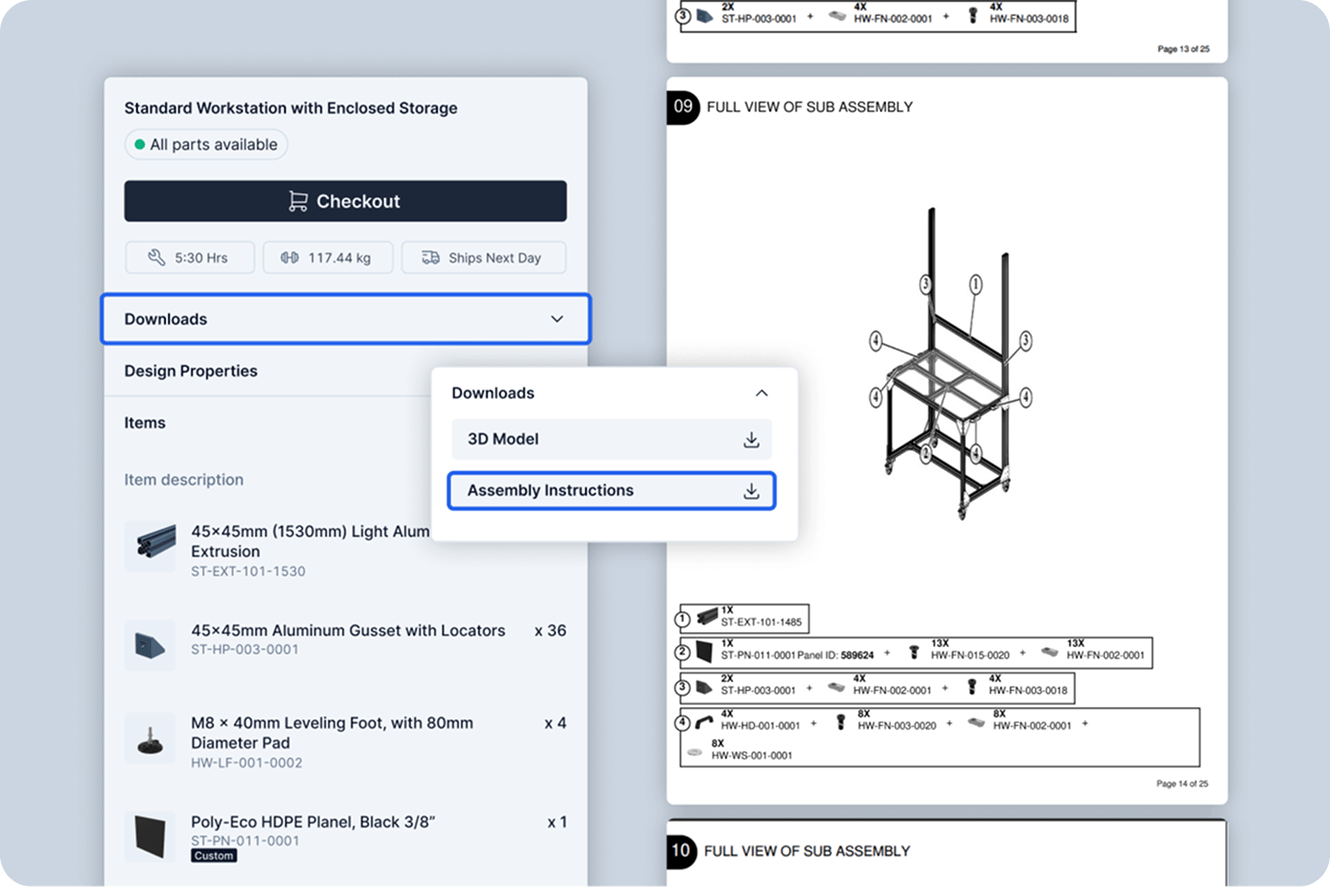

Flexible Assembly Options

Choose How Your Design Comes Together

Get your design exactly how you need it, self-assemble with clear instructions or have the Vention team handle full or partial assembly to save time.

Build It Yourself

Receive flat-packed boxes for easy handling

Assemble using just one tool

Every part is labeled with engraved part numbers

Pre-Assembled for You

Receive fully or partially assembled designs

Custom packaging to speed up final assembly

Reduce on-site assembly time and effort

Contact Us

Talk to an Automation Expert

Get personalized guidance for your next project within 24 hours.

Workstations & Workbenches Educational Resources

Resources to Start Building Fast

Access comprehensive documentation, technical guides, and tutorial videos to help you design, build, and optimize your custom workstations.