Robotic Sanders and Surface Finishers

Introduction to Robotic Sanding and Finishing

In manufacturing, achieving the perfect finish on products is not just a matter of aesthetics but a critical factor influencing functionality, durability, and customer satisfaction. As industries continually seek advancements to enhance quality and efficiency, robotic sanding and finishing technologies emerge as pivotal innovations, revolutionizing the way we approach surface preparation and finishing tasks.

The Evolution of Sanding and Finishing

Traditionally, sanding and finishing were labor-intensive processes fraught with inconsistencies and occupational hazards. The innovation of robotic sander technologies has introduced new levels of precision, consistency, and safety. Robotic sanding and finishing systems leverage advanced automation to execute repetitive and intricate tasks with unmatched accuracy, introducing a new era of manufacturing excellence.

The Benefits of Robotic Sanding and Finishing Automation

Consistency and Quality

One of the most compelling advantages of employing robotic sanding and surface finishing systems is their ability to maintain unwavering consistency. Unlike manual processes that are susceptible to human error and fatigue, sanding robots can replicate the exact same motion and pressure, ensuring every product meets stringent quality standards.

Efficiency and Productivity

Robot sanders and surface finishers can operate around the clock, significantly reducing the time required to complete sanding and finishing tasks. This continuous operation, free of breaks or shifts, dramatically boosts productivity, allowing manufacturers to meet growing demands without compromising quality.

Safety and Workplace Ergonomics

Sanding and finishing tasks often expose workers to dust, chemicals, and strain injuries. By delegating sanding and finishing tasks to robotic sanders, industries can vastly improve workplace safety and ergonomics, protecting their workforce from potential health hazards.

As we delve deeper into the technological foundation and practical applications of robotic sanding and finishing, we will explore the types of robots used, their integration into existing systems, material considerations, and strategies for process optimization. This blog aims to empower manufacturers to make informed decisions about adopting robotic solutions—paving the way for enhanced operational quality, efficiency, and safety.

Robotic Sanding Technology and Equipment

Robotic sanding and finishing incorporate a variety of technologies and equipment designed to optimize manufacturing processes. Understanding the types of robotic sanders used, the characteristics of sanding robot end-of-arm tools (EOATs), and how these systems integrate with existing manufacturing setups is crucial for anyone considering adopting these solutions.

Types of Robots Used in Sanding and Surface Finishing

The choice of robot used in sanding and surface finishing is very important. Each robot type offers different benefits, depending on your application:

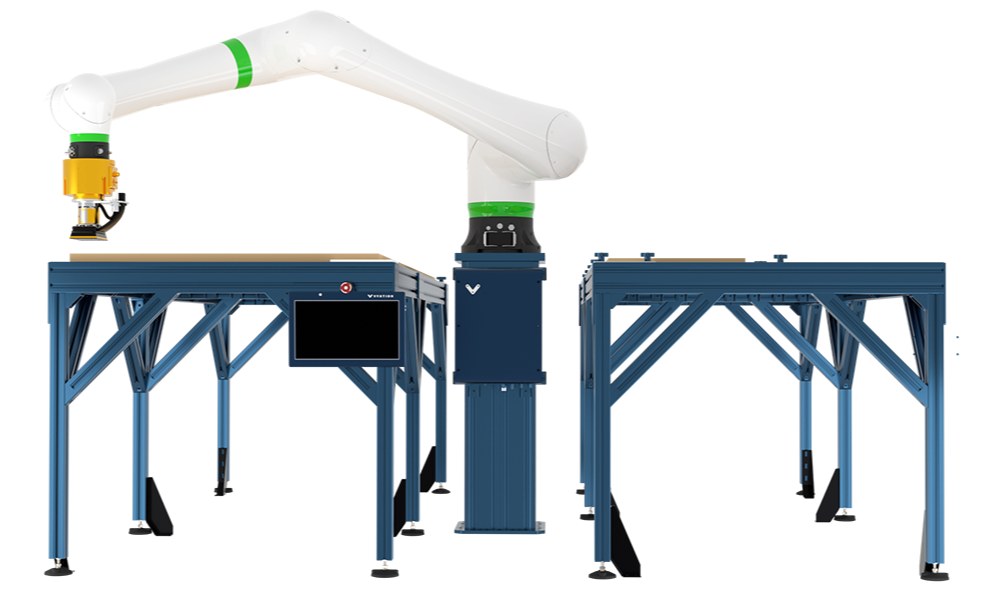

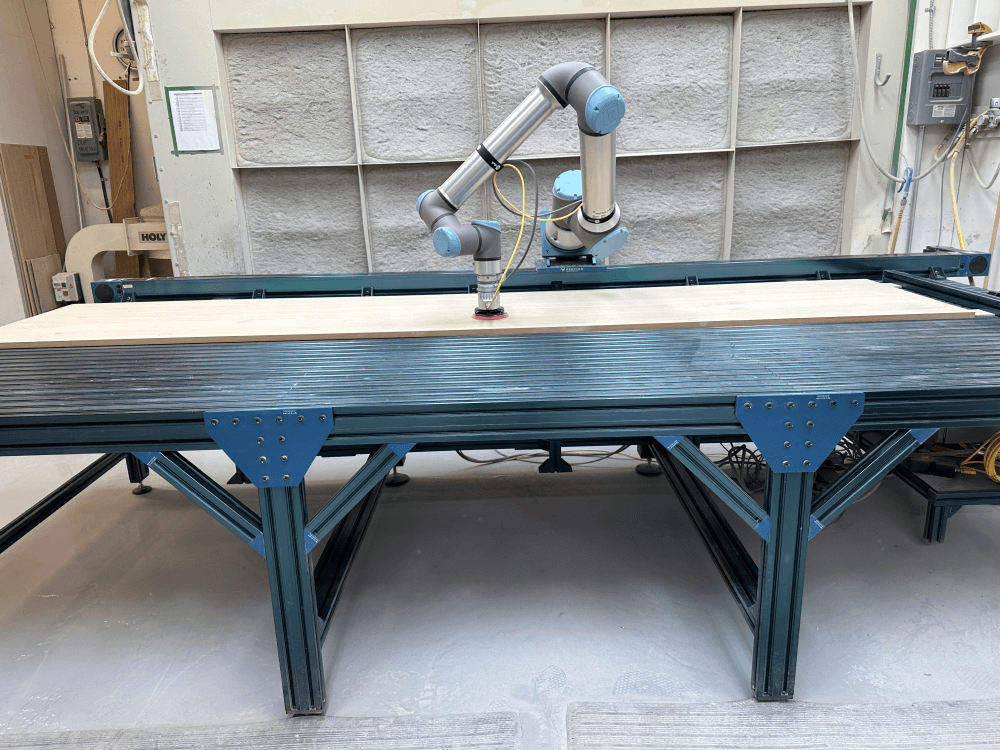

Articulated Cobot Arm Sanding

These robotic sanders feature multiple joints, offering a range of motion that closely mimics the human arm. Robotic sanders have multiple degrees of freedom due to the numerous joints in their robot arms, providing high versatility. Articulated cobot arm sanders are capable of performing complex sanding and finishing tasks, making them suitable for applications requiring high precision and flexibility.

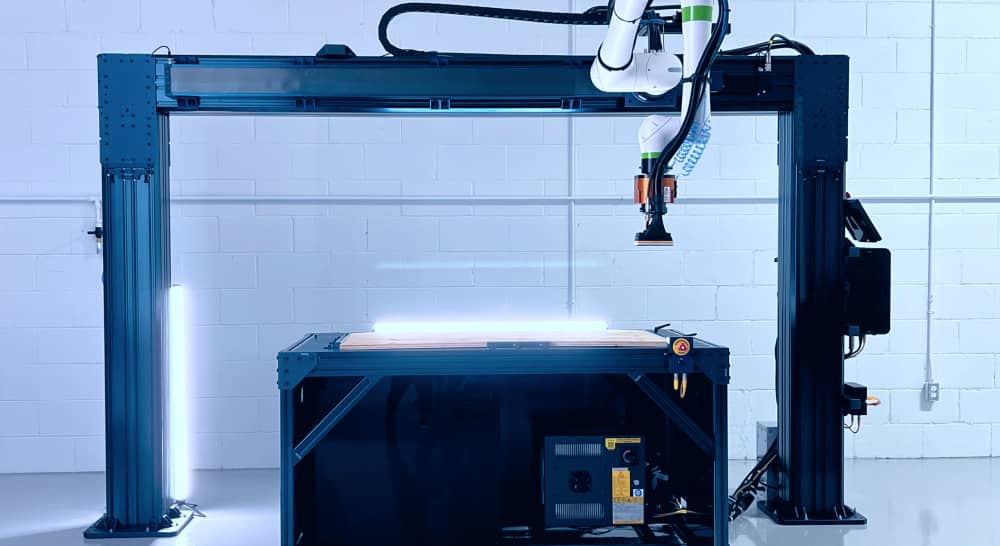

Cartesian Robot Sanding

Also known as linear robots, cartesian systems used as robotic sander operate along three orthogonal axes (X, Y, and Z). They offer straightforward, precise movements and are commonly used for tasks that require linear or rectangular path operations, such as flat surface sanding and finishing.

SCARA Robot Sanding

Selective Compliance Assembly Robot Arm (SCARA) robots are designed for high-speed, precise operations in a horizontal plane. They are particularly effective for tasks that require fast, repetitive motions, such as buffing or polishing flat surfaces.

End-Effectors and Tools for Robotic Sanding and Finishing

The choice of end-effectors and tools in robotic sanders is critical for achieving desired outcomes in sanding and finishing. These components vary significantly in characteristics and must be selected based on specific task requirements:

Robotic Sanding Tools

Sanding robot end-of-arm tools include belts, discs, and brushes, each suitable for different materials and finishes. The selection criteria often involves considering the material’s hardness, the desired surface finish, and the tool’s durability. Orbital sanders with sanding disks are typically the most versatile, while rectangular sanding pads are used for sanding tight corners.

Robotic Polishing and Buffing Tools

Typically made from softer materials, these tools are used for final finishing tasks to achieve a high gloss or mirror finish. Material compatibility and the level of finish required are key selection factors.

Customization Options

Depending on the application, customization of end-effectors may be necessary to accommodate unique shapes, sizes, or surface contours of the workpieces.

Integrating Robot Sanders with Existing Manufacturing Systems

To deliver maximum value, robotic sanding and finishing systems must seamlessly integrate with existing manufacturing infrastructures, such as CNC machines and conveyor systems. This integration facilitates automated workflows, where tasks like material handling, processing, and quality control are interconnected, yielding a streamlined, efficient production line.

CNC Machine Integration

Robotic sanders can be programmed to work with CNC machines, performing post-processing tasks such as sanding or polishing the machined parts after they are loaded or unloaded.

Conveyor Systems

Integration with conveyor systems allows for the continuous processing of workpieces. Robots can be stationed along the conveyor to perform sanding or finishing tasks on parts.

Specific Challenges in Sanding and Finishing Wood and Soft Metals

The process of sanding and finishing wood and soft metals presents unique challenges that necessitate careful consideration of material properties, tool selection, and finishing techniques. Adjustments in robotic settings for different materials are crucial for achieving the desired surface qualities. Here’s an in-depth look at these challenges and the techniques employed to overcome them.

Adjusting Robotic Sander Settings for Different Materials

The choice of abrasive grit plays a pivotal role in achieving the desired finish on wood and soft metals. For wood, starting with coarser grits and progressively moving to finer grits is standard practice to remove imperfections and prepare the surface for finishing. In contrast, soft metals such as aluminum may require medium to fine grits to avoid excessive material removal and to achieve a smooth finish. The automation system could also automatically change sanding discs based on the processed material to maintain efficiency and effectiveness.

Sander Pressure and Speed

The pressure exerted by the sanding tool and the speed at which it operates are critical settings that vary significantly between wood and soft metals. Robotic systems can utilize built-in force sensing capabilities to adjust the pressure in real time, ensuring consistent quality across different materials.

Orientation and Path Planning

The direction of sanding and the path followed by the tool can affect the final appearance and texture of the material. Wood grain orientation dictates the sanding direction to avoid lifting the grain or causing splintering. For soft metals, cross-hatching patterns are often used to create a uniform surface finish. Advanced robotic programming allows for precise control over the tool’s path, adapting to the contours and specific requirements of each piece.

Techniques for Achieving Desired Surface Qualities

Achieving the desired surface quality often involves multiple sanding steps, each with a specific goal, such as material removal, smoothing, or preparing for finishing coatings. Robots are programmed to execute these steps in sequence, automatically adjusting settings between stages to seamlessly transition from rough to fine finishes.

Integration of Robotic Polishing and Buffing

After sanding, both wood and soft metals may undergo polishing and buffing processes to enhance their appearance. For metals, polishing can achieve a mirror-like finish, while buffing wood can bring out its natural beauty and prepare it for sealants or stains. Robotic systems equipped with variable tool attachments can switch between sanding, polishing, and buffing tasks without manual intervention, streamlining the finishing process.

Robotic Sanding and Surface Finishing Process Optimization

Programming and Path Planning

Efficient material removal and surface finish are critical components of any sanding or polishing task, and these aspects heavily rely on precise programming and path planning. The integration of robotic sanding and finishing software with the corresponding sanding robotic arms allows for detailed programming, ensuring that every movement of the robot is optimized for the best possible outcome.

By meticulously planning the path the sanding or polishing tool takes over the material’s surface, businesses can significantly enhance the uniformity and quality of the finish. This optimization not only improves product quality but also reduces the time required for each task, leading to significant productivity gains.’

Implementations of Robotic Sanding and Surface Finishing

Furniture Manufacturing Industry

Furniture manufacturers are implementing robotic sanding in their production lines to improve the efficiency and quality of wood surface finishes. Sanding cobots, programmed with detailed path planning, are doubling the production rate while maintaining a consistently high-quality finish.

Replacing manual sanding with robotic systems can increase production speed for wood furniture components, which you’ll read about in the case study below. These implementations highlight the versatility of robotic sanding and polishing systems across different materials and industries.

Aerospace Industry

Aerospace companies face challenges in maintaining the quality and consistency of surface finishes on aircraft parts. By adopting a robotic polishing system equipped with force-sensing capabilities, companies are gaining more precise control over the pressure applied during the polishing process, resulting in an enhanced surface finish that meets stringent industry standards, reducing the time required for each part and significantly lowering the risk of manual errors.

Automotive Industry

In the automotive sector, leading manufacturers are implementing robotic sanding and polishing systems for finishing car body components. On average, the results are a reduction in manual labor costs and a decrease in processing time per component, showcasing the significant efficiency and cost-saving potentials of robotic sanding.

Quality Control and Finishing Standards in Robotic Sanding and Polishing

Robotic sanding and polishing technologies are transforming the manufacturing landscape, offering unprecedented consistency and efficiency in finishing processes. As industries strive for excellence, ensuring uniformity in finish quality across batches and meeting rigorous industry standards have become paramount. This section explores strategies for maintaining high-quality control and achieving finishing standards that meet or exceed expectations.

Ensuring Consistency in Finish Quality Across Batches

Robotic systems, with their precision and repeatability, play a crucial role in achieving consistent finish quality across batches. By leveraging advanced sensors and feedback mechanisms, these robots can adapt to variations in material surfaces, ensuring each part receives the same level of attention and finish, regardless of its position in the production line. Employing robots minimizes human error and variability, leading to a uniform product quality that is difficult to achieve manually.

Programmable Precision

Robotic systems are programmed to follow exact parameters, such as force applied and movement speed, ensuring every part is sanded or polished to the same standard.

Adaptive Control

Through the use of force-sensing technology and real-time feedback, robots can adjust their operations based on the material’s response, accommodating any inconsistencies in the workpiece.

Meeting Industry Standards for Surface Finish

Adhering to industry standards for surface finish, such as roughness and gloss levels, is essential for manufacturers to remain competitive and ensure customer satisfaction. Robotic finishing systems are equipped with state-of-the-art technology to meet these standards precisely.

Techniques for Inspection and Quality Assurance in Robotic Finishing

Implementing robust inspection and quality assurance techniques can help validate the consistency and quality of finishes produced by robotic systems. These techniques include:

Automated Inspection Stations

Integrating automated inspection stations within the production line allows for immediate and non-destructive testing of surface finishes, identifying defects or deviations from standards without slowing down the production process.

Statistical Process Control (SPC)

Utilizing SPC methods enables manufacturers to monitor and control the finishing process through data analysis, identifying trends that may indicate potential quality issues before they become problematic.

Feedback Loops

Establishing feedback loops between the inspection systems and the robotic finishing units ensures continuous improvement. Adjustments can be made in real-time based on inspection outcomes, enhancing the overall quality control process.

Calculating ROI for Implementing Robotic Sanding Systems

ROI calculation for robotic sanding and finishing systems involves comparing the costs saved and additional revenue generated against the initial and operational costs of the robotic system.

Basic Formula for Robotic Sanding and Surface Finishing ROI

Annual Cost Savings

Calculate the difference between the costs associated with manual processes and those expected with the robotic system. This includes labor cost savings, reduced downtime, and material savings.

Incremental Revenue

Estimate the additional revenue generated from increased production capacity, improved quality leading to higher sales prices or volumes, and potential market share gains due to enhanced capabilities.

Annual Operational Costs

Sum up the costs related to running the robotic system, including sanding robot maintenance, utilities, and any additional labor for supervision or operation.

Initial Equipment Investment

Aggregate costs of purchasing, installing, and commissioning the robotic system, along with training employees to operate it.

While the initial investment in robotic sanding and finishing systems may be substantial, the long-term economic benefits, including labor cost savings, increased productivity, consistent quality, and reduced material waste, contribute to a compelling ROI. Businesses should conduct a thorough analysis, considering both direct and indirect cost savings and revenue enhancements, to make an informed decision about adopting robotic systems for their sanding and finishing needs.

How to Implement Robotic Sanding and Finishing Systems

Implementing robotic sanding and finishing systems involves a structured approach to ensure that the technology aligns with your production goals, enhances productivity, and addresses the quality requirements of your projects. Below are the steps for evaluating and selecting robotic sanding and finishing systems, along with insights into training, skill development, and vendor selection.

Evaluating and Selecting Robotic Systems

Assessment of Needs

Begin by identifying the specific needs of your sanding and finishing applications. Consider the types of materials you work with, the complexity of parts, and your production volume. Refer to robotic sanding examples from your industry for insights on successful implementations.

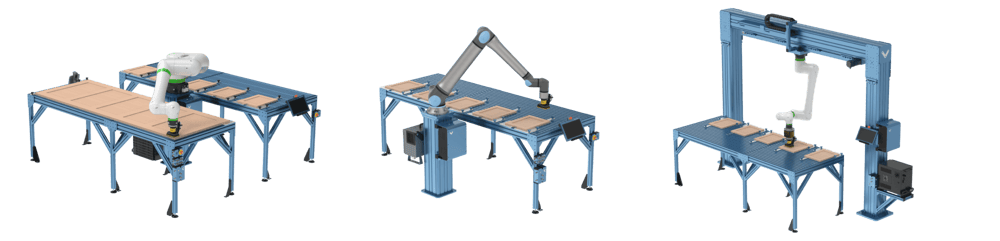

Sanding and Finishing Robot Arm Research

There are various robotic sanding and finishing configurations available. Assess the workstation and kind of volume that you need, and select a pre-designed robotic sanding workstation that fits your needs, or customize your own robotic sanding cell to match your unique process.

Capability Matching

Match the capabilities of the robotic systems with your specific needs. Consider the system’s flexibility, precision, and compatibility with different sanding and finishing tools. Evaluate if the system can adapt to various shapes and sizes of parts.

Cost-Benefit Analysis

Conduct a thorough cost-benefit analysis. Consider the initial investment, expected productivity gains, quality improvements, and potential for reduced labor costs. Factor in the fast ROI and use tools like the one mentioned in the ROI section above.

Vendor Selection and Partnership

Robotics Vendor Case Studies

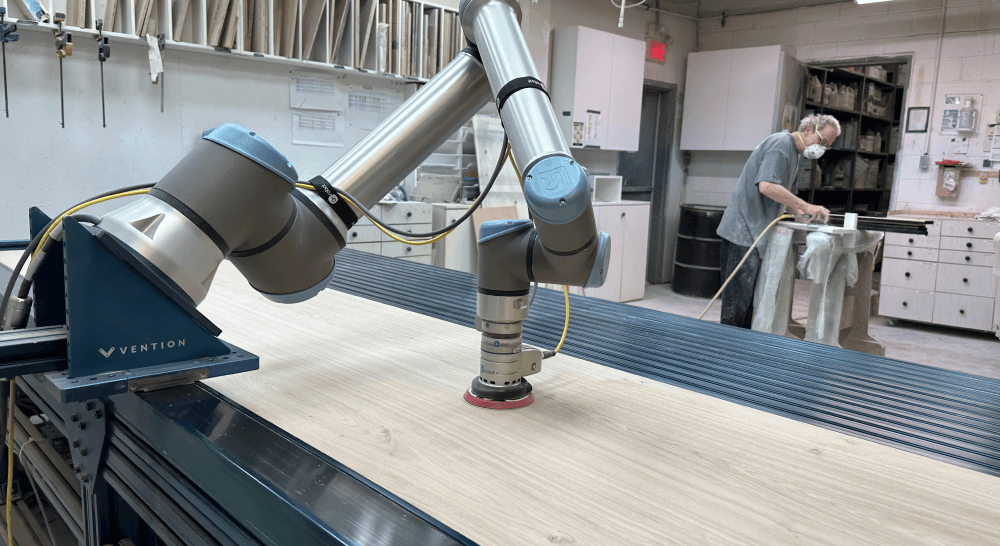

Manufacturers should research real-world cases from vendors to see the robotic systems in action. This will provide insights into the ease of use, performance, and integration capabilities with your existing production line. Vention’s robotic sanding and surfacing finishing case study is a perfect example of proof-of-concept. The manufacturer, Classic Woodwork, is quoted saying:

“In the woodwork industry, automating processes is hard. It’s all tailor-made. We often think it’s only meant for high-volume productions, but following discussions with Vention, we realized it was accessible for us too.” - Aboudi Greige, Assistant Director of Operations, Classic Woodwork

This realization from this small, bespoke woodworker that robot sanding technology was available to them and easy to use through Vention’s accessible technology allowed them to alleviate manual, monotonous labor demands on employees so they could focus on high-value tasks.

Collaborative Development

Consider vendors who are willing to work collaboratively with you to customize the robotic sanding and finishing systems to your specific requirements. This can include custom robot end of arm tooling, software adjustments, and deployment services such as setup support and troubleshooting. Vention will work with you to deeply understand your operation and requirements, then co-develop a solution using your knowledge and our automation expertise to ensure the success of your robot sander cell implementation.

Long-Term Relationship

Aim for a long-term relationship with your vendor for ongoing support, maintenance, and future upgrades. Vention is dedicated to your success and supports you throughout the long-term operation of your machine.

Through MachineAnalytics, our remote monitoring software, receive detailed data and insights on the health and performance of your machines.

RemoteView offers a 24/7 live video stream of your machine running in real-time to give you peace of mind that your machines are performing as expected and have a quick reaction time when an event occurs.

Remote Support offers on-demand customer support from our automation and deployment experts, available at the click of a button. These three products work together to ensure that your robotic systems continue to meet your production needs efficiently.

Robotic Sanding Training

Stemming from the importance of a good long-term relationship with your robotic sanding system partner is the available training on that system. How many times have you heard these industrial robotic arms being referred to as “boat anchors” because they never get deployed or operate as promised and, therefore, become dead weight?

We’ve heard it a lot, and to counter this perception, Vention offers in-person or virtual robotic automation training sessions designed to provide manufacturers with the practical skills and knowledge to become an automation expert. With hands-on guidance from our integration coaches, feel empowered to take ownership of your machines and drive innovation in your operations.

Conclusion

Implementing robotic sanding and finishing systems is a significant step toward enhancing productivity and quality in manufacturing. Manufacturers can make substantial improvements in their production processes by carefully evaluating and selecting the right systems, investing in training and skill development, and establishing a strong partnership with a reliable vendor.