In today’s fast-paced manufacturing industry, efficiency in industrial automation has become paramount. One of the key technologies driving this transformation in the manufacturing process is the collaborative robot or cobot.

Cobot palletizers are revolutionizing the way we package, stack, and organize goods on factory floors. Their ability to work alongside human operators has made them an invaluable asset in optimizing production lines and increasing productivity. But with various options available in the market, how do you choose the right cobot palletizer for your factory floor?

Vention’s Manufacturing Automation Platform (MAP) offers a streamlined experience to help you choose the perfect fit for your unique requirements. In this blog post, we’ll show you how Vention can help you choose the correct cobot palletizer for you.

1. Assess Your Application

Before diving into the world of cobot palletizers, you must thoroughly assess your application requirements and SKUs. Consider factors like product type, weight, size, and the palletizing pattern. Your cobot palletizer should be capable of handling the specific tasks you need. Vention has experts who can help evaluate your production line and suggest the most suitable solutions for you. Our cobot palletizers are so flexible and simple to redeploy that you can start with a selection of SKUs today and update your program down the road as your business needs change.

2. Payload and Reach

Payload capacity and reach are crucial technical specifications to consider when selecting a cobot palletizer. Ensure your chosen cobot can accommodate the weight of your products and reach the desired palletizing positions. As a rule of thumb, you can expect cobot palletizers to be able to palletize products of up to 25-30kg. As for the reach of the robot, our online simulation capabilities and our team of experts will help you determine the optimal setup, whether it’s a fixed pedestal or a telescopic column. With MAP, all options are possible since our user-friendly platform allows you to customize and configure your cobot palletizer to meet your unique needs. Our modular approach ensures that your automation solution can adapt alongside your manufacturing floor.

3. Cost and ROI

When designing a cobot palletizer with Vention, cost transparency is at your fingertips. The platform assists in understanding the impact of design choices on costs. This makes it simpler to calculate the expected ROI and stay within budget for your project. To easily calculate ROI in a few simple steps, try out our ROI calculator.

4. Safety Features

Cobot palletizers work safely alongside human operators. To ensure safe operations, choose a cobot that adheres to safety rules and has safety features. Force-torque sensors and collision detection technology can be built-in features for different cobot models. When paired with external safety devices such as area scanners and light curtains (all available within Vention’s parts library), you can rest assured your workforce will be safe to work alongside your machine. All of these components are directly compatible will Vention’s automation ecosystem, allowing you to add a safety device to your setup with no integration required.

5. Programming and Ease of Use

Cobots are user-friendly by design, but the ease of programming and integration with your existing equipment is crucial. Consider a solution with an intuitive software interface, such as Vention’s MachineApp for Palletizers.

MachineApp for Palletizers is a purpose-built, code-free application to operate your machine. It saves weeks of manual programming time and can be learned, configured, and operated in minutes. With the easy-to-use interface, machine operators can be quickly trained and SKU changeovers and adaptations are easily made for evolving productions.

6. Flexibility and Scale

Vention designed the Manufacturing Automation Platform to provide not only flexibility but also to scale. With our modular components pre-tested for compatibility, you can easily reconfigure or expand your application or full system as your manufacturing needs evolve. This built-in scalability ensures that your investment remains valuable and adaptable in the long term.

7. End-of-Arm Tooling

End-of-arm tooling (EOAT) is a crucial component of your cobot’s interaction with products and pallets. Vention’s platform has many modular EOAT components. You can use them to create and adjust grippers, vacuum systems, or clamps for products such as cardboard boxes, bags, trays, and more.

8. Support and Maintenance

Vention’s commitment to customer support guarantees a seamless transition to automated manufacturing. We provide everything you need for installing, training, and maintaining your cobot palletizer, supporting you throughout its entire lifespan. With game-changing Remote Support, you can get on-demand support in less than 10 minutes for fast troubleshooting and issue resolution. Explore our full service and support offerings.

Automating palletizing with Vention

|

|

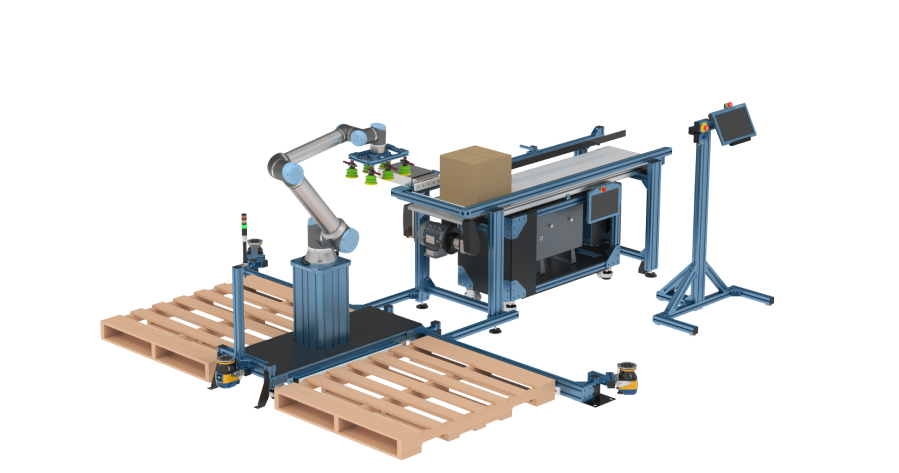

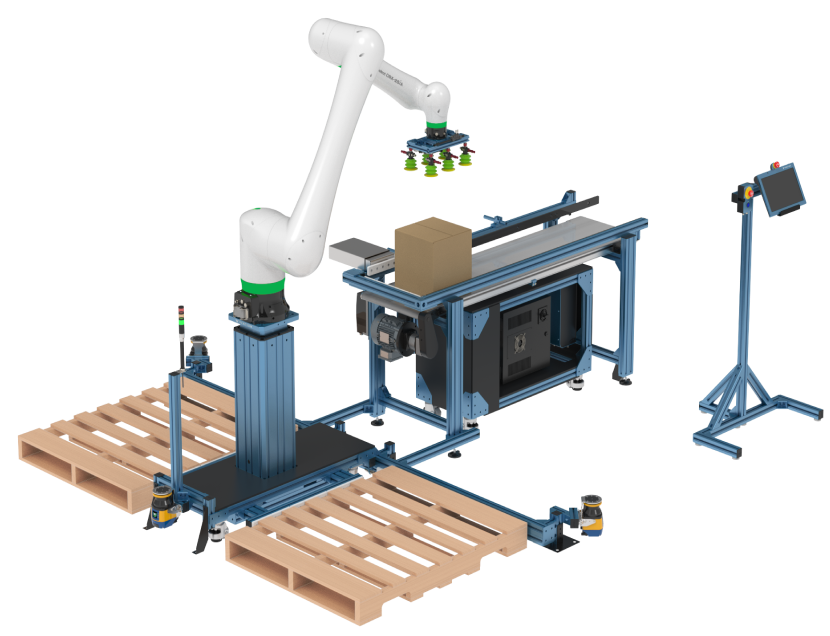

| Medium Payload Vention Cobot Palletizer, pictured with Universal Robots UR10e | Heavy Payload Vention Cobot Palletizer, pictured with FANUC CRX23iA |

Choosing the correct cobot palletizer for your factory is a big decision that can greatly affect your productivity and efficiency. Now that you know what to consider in choosing a cobot palletizer, check out our cobot palletizer configurator to generate a template that matches your specific needs. With Vention, you are never alone in your automation journey. The support, flexibility, scalability, and cost transparency provided by Vention make us an invaluable partner in streamlining your factory automation. Invest in the future of manufacturing with Vention and experience the benefits of a seamlessly integrated cobot palletizer.

Explore our cobot palletizer solutions. Learn more about our services and support offerings.

Are you ready to get started? Talk with our team today.