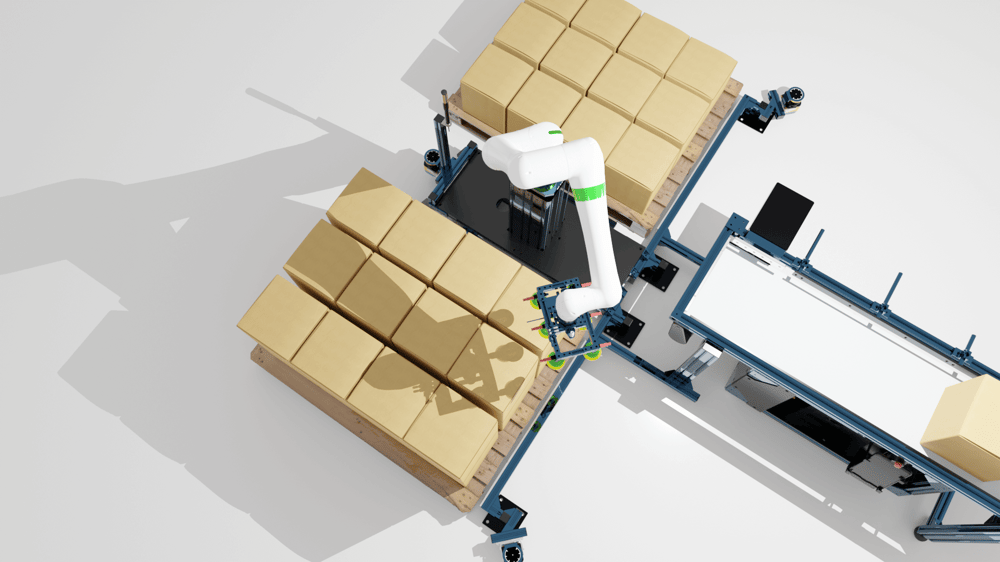

One of the key strategies that has transformed manufacturing is robotic automated palletizing. This process arranges products or materials on pallets in a systematic way, with benefits that go beyond convenience.

In this blog post, we’ll look at the benefits of automating palletizing and why it’s important for businesses globally.

1. Streamlined operations and increased efficiency

Automated palletizing ensures fast and accurate results. A cobot or industrial robot palletizer can handle large volumes of products without stopping, outperforming manual processes. This results in faster production cycles, reduced lead times, and an increase in overall output.

2. Enhanced safety and reduced labor costs

Safety is a top priority in any manufacturing setting. Automating repetitive tasks and physically demanding aspects of production lines reduces injuries and labor costs. Now, these workers are available to focus on value-added tasks, such as operating the equipment and assembly lines.

A recent study found that as many as 24% of male warehouse workers are suffering from low back pain. This is avoidable with automation.

3. Optimized storage space

Manufacturers can create automated palletizing systems to optimize space within warehouses and distribution centers. The robotic arm stacks pallets more efficiently to maximize vertical space. They also pack the pallet load more densely and with greater stability, lowering the overall footprint required for storage.

Customize your pallet configuration to optimize storage space based on your unique specifications.

4. Flexibility

Modern robotic palletizing processes are designed to be highly adaptable and flexible. Most automatic palletizers can handle a wide range and large scale of product types, sizes, and packaging configurations. This flexibility is crucial for businesses to quickly adjust to market demands without making significant changes to their palletizing systems.

5. Cost savings

Automating packaging saves businesses money by making operations more efficient, reducing labor costs, and maximizing storage space. Industrial robots and robotic palletizing equipment provide a strong return on investment overtime. With a solution from Vention, manufacturers can expect to see ROI in as little as nine months or less.

You can easily and accurately calculate your unique ROI using this ROI Calculator.

6. Data-driven decision-making

Some automated packaging systems are equipped with sophisticated sensors and software that provide real-time data on operations. This data can be leveraged for analytics, offering insights into production efficiency, equipment performance, and overall supply chain dynamics. This information empowers businesses to make data-driven decisions on manufacturing processes for continuous improvement.

See Vention’s MachineAnalytics for the most accurate, real-time tracking of machine health and performance data.

7. Precision and consistency

Humans are prone to mistakes, but automated systems provide a level of precision and consistency that is unparalleled. The items are organized with great precision, reducing mistakes in piling and making sure every pallet is evenly filled. This precision is critical for increasing productivity to get products to your customers faster.

Robotic Automated Palletizing with Vention

Automated palletizing is beneficial because it is efficient, safe, optimizes storage space, and saves costs. If you are interested in adding a cobot or industrial palletizer to your production line, Vention has the solution for you.

Are you prepared to start your journey to automated palletizing? Read our blog “Mastering the Basics: A Guide to Palletizing 101” for everything you need to know. Ready to chat with our team? Talk to an expert today.