Calculating return on investment (ROI) is crucial for demonstrating the long-term value of an industrial automation project and securing management approval. However, achieving an accurate ROI calculation can be cumbersome due to the numerous factors involved in such projects.

To simplify this process for manufacturers, Vention has created a straightforward ROI calculator that requires just a few inputs and delivers accurate results. This guide outlines the essential components necessary for calculating ROI and provides instructions on how to use the calculator. It serves as the fifth blog in the ‘Kickstarting Your Automation Journey’ series.

Components of the ROI model for industrial automation

Industrial automation business cases are usually built on four value-creating considerations: labor cost savings, quality improvement, incremental production volume, and operator safety enhancement. These benefits must be weighed against the overall costs of the automation project. Costs to consider extend beyond the initial hardware and software investment to include system integration, operator training, spare parts kits, as well as the net present value of expected maintenance costs.

Once the costs have been properly considered, it’s time to deep-dive into each element that drives value creation:

Labor cost savings

Labor cost savings can be easily quantified by comparing total labor costs with and without automation. However, for more accurate results, factors such as operating human efficiency (OHE) and operating equipment efficiency (OEE) must also be considered. These metrics account for the efficiency difference between human labor and automated equipment. Due to factors like breaks for human workers and setup/maintenance for machines, achieving consistent operation for a full 8-hour shift is not always feasible. On average, OHE tends to range around 80%, while OEE ranges around 90%+.

Labor shortages experienced by several manufacturers could be implicitly factored into the labor hourly rate by factoring the annual cost of re-hiring and operator training on a per-hour basis

Quality improvement

Quality is improved due to the repeatable and consistent nature of automated processes. This could result in a reduction in defects and minimized consumable usage. For instance, in manufacturing operations such as drilling or deburring, a more reliable process results in fewer rejected parts and less need for rework. If the process includes sealant, glue, or paint application, automation will ensure that just the right quantity is used every time, minimizing consumable consumption. Overall, quality improvement helps reduce the product unit cost.

Incremental production volume

Implementing automated equipment typically reduces cycle times compared to manual processes, potentially generating incremental production volume that can be sold to generate revenue. However, this approach should be used with caution, as market acceptance and pricing of additional supply need to be tested. If quantifying these gains is challenging, treat productivity improvements as qualitative benefits without assigning specific values.

Operator safety enhancement

Industrial automation significantly enhances operator safety by reducing direct human interaction with hazardous tasks and environments. By delegating dangerous and repetitive tasks to automated systems, operators are less exposed to risks such as extreme temperatures, toxic substances, and machinery-related accidents.

Using the Vention industrial automation ROI calculator

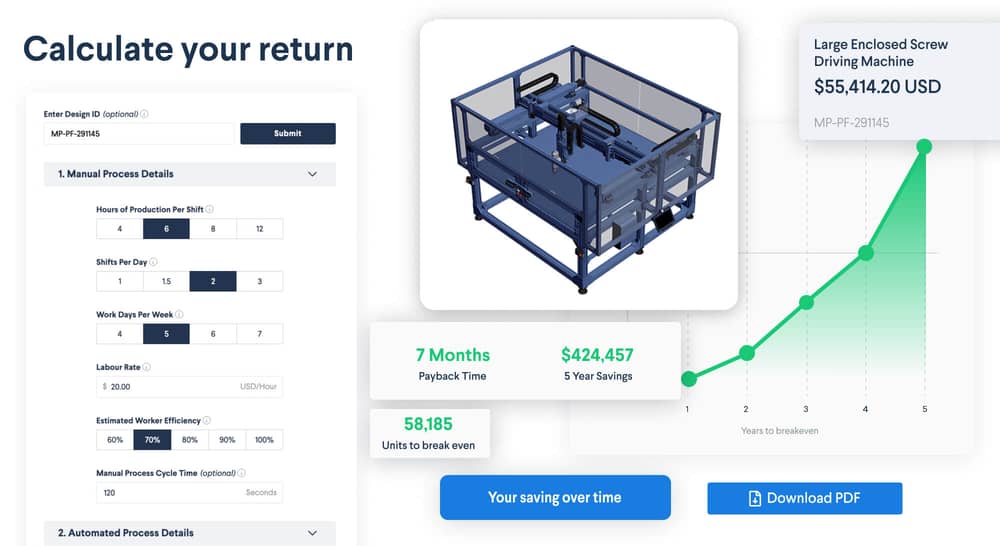

Thankfully, new tools have emerged that make calculating an accurate ROI simpler. The Vention industrial automation ROI calculator breaks down each component into easily quantifiable inputs.

- Access the ROI calculator here.

- Enter your Design ID, and your equipment hardware cost will automatically populate. If you do not have a Design ID, you can enter the equipment cost manually later on.

- Enter your Manual Process Details and Automated Process Details.

- Click Calculate. Your savings will populate, showing your estimated payback time, units to break even, and total savings after five years. You can easily share this information—just copy the link and send it to your team!

Calculating ROI on your next industrial automation project is that easy. Try it out for yourself today.

Conclusion

Before embarking on an industrial automation project, use this guide to determine ROI. With a strong ROI, your project is more likely to be approved, and management will be more likely to support future automation endeavors.

This is the fifth and final blog in the ‘Kickstarting Your Automation Journey’ series. Read ‘A guide to kickstarting your industrial automation journey,’ ‘How to choose which manufacturing process to automate first,’ ‘Five benefits of building an Advanced Manufacturing Team,’ and ‘Structuring your Advanced Manufacturing Team for robotics and industrial automation.’

Explore the blog for industry news and updates.

Contact us to kickstart your automation journey today.