Once you’ve chosen the correct two-finger gripper for your robot arm (see Part Two of our “Building a Robot Cell” series), it’s time to choose the vacuum gripper. In a robot cell, vacuum grippers are typically used to move packaging like boxes and bags, or large materials like panes of glass or sheet metal, with little to no risk of damaging the product.

Creating systems that use a vacuum for gripping is relatively simple and inexpensive. Because vacuum grippers can be used in a wide range of applications, it’s important to match the vacuum gripper to the materials being moved. This might seem obvious, but moving or stacking different materials requires careful consideration of many essential variables. To find or create the right vacuum gripper for your application, you must consider these three factors:

- Vacuum source

- Type, size, and number of suction cups

- Surface porosity of the object to be handled

Vacuum source: Electric vs. pneumatic

A vacuum is created by pushing compressed air through a small opening to produce negative pressure (venturi effect). Vacuum is typically measured by the speed at which air is removed from a system, in standard cubic feet per minute (scfm). Handling materials safely requires a sufficient and continuous vacuum flow.

Electric vacuum pumps

Electric pumps can create a vacuum when no compressed air supply is available. They offer lower maintenance costs and are quieter to operate than pneumatic pumps. However, electric pumps mounted on a robot wrist are limited in size and in how much negative pressure they can create, which might make them more expensive than pneumatic vacuum pumps. Electric pumps like this work best when handling light, non-porous objects.

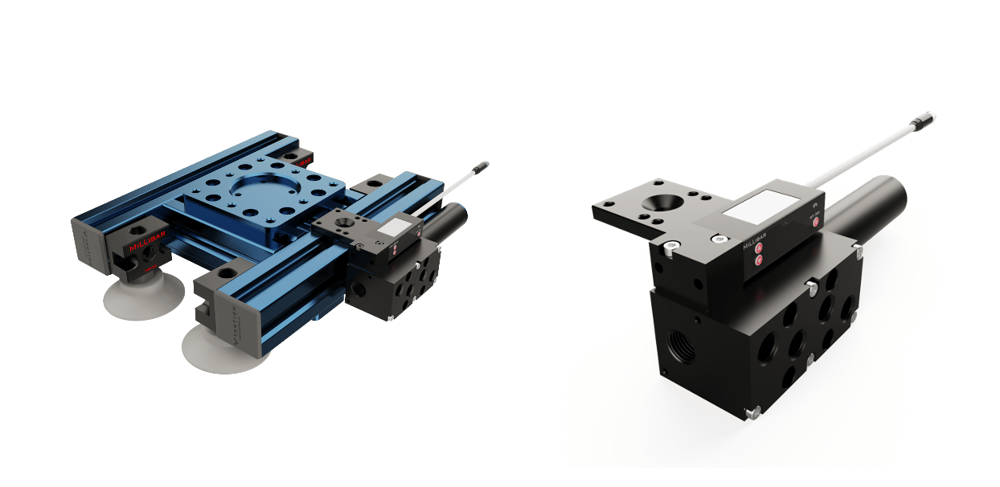

Pneumatic vacuum systems

When a compressed air supply is available, a venturi with a pneumatic vacuum pump can create strong and continuous vacuum flows for picking up heavier, more porous objects. Such vacuum systems are highly scalable, and they’re easy to customize by attaching valves, cups, and hoses to the venturi and the pump. Add 1,4,6,8 (or more) cups to accommodate the pack to be picked. While this type of system is scalable, creating too many junctions in the system may impact performance as the likelihood of small leaks will increase.

Vacuum cups

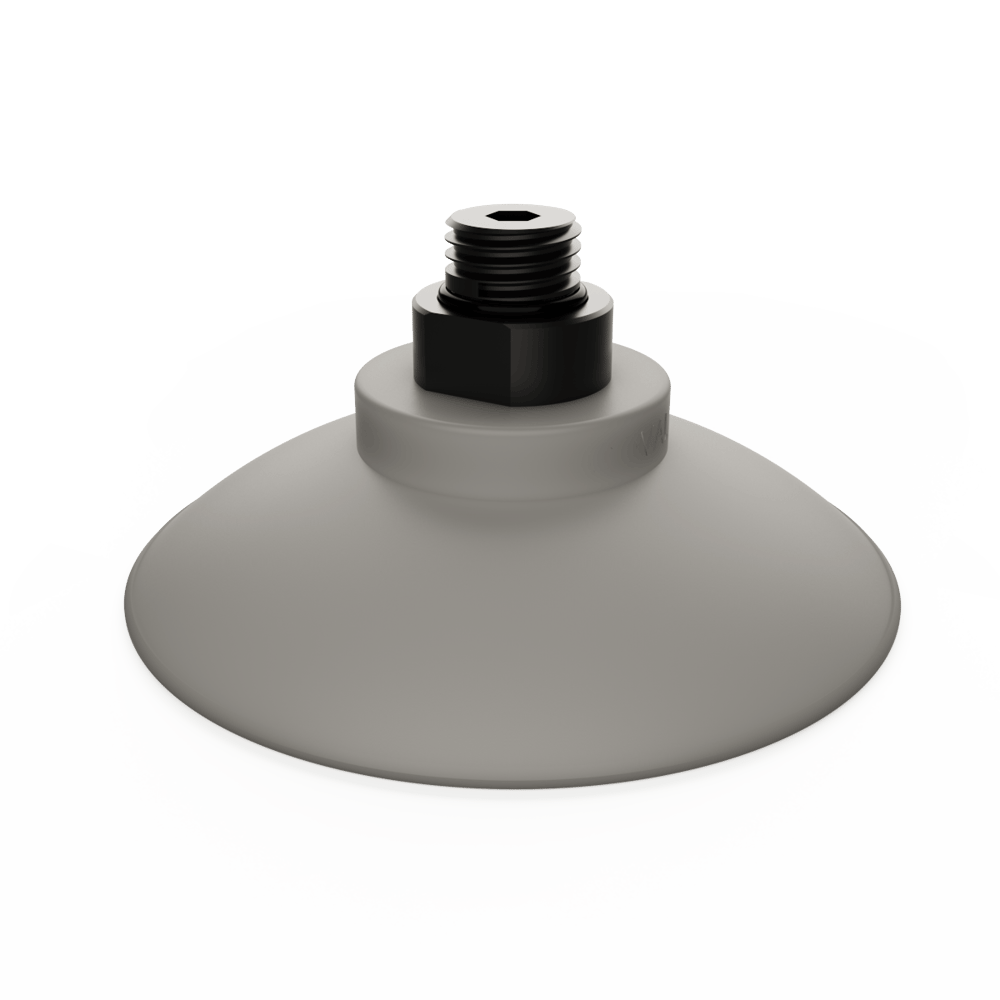

Aside from the pump, the other main component of any vacuum gripper is the suction cups.

Cup type

Flat cups have less inner volume, which enables quicker gripping. They are generally used on smooth, non-porous material, and are also ideal if the application requires holding the object vertically, because they’re fairly rigid and less likely to be bent out of shape.

Bellow cups have one or more ribbed convolutions that allow them to grip a wide range of uneven surfaces and pick non-uniform objects. These are ideal for handling objects that vary in shape and size.

Cup size, shape, material, and count

Cup size affects how much weight can be handled. All else equal, larger suction cups can apply a greater vacuum flow/force, and therefore lift heavier objects.

Whereas most suction cups have a circular shape, oval cups can be better for manipulating long and narrow parts. Moreover, cups are available in a variety of materials including rubber, silicone, neoprene, polyurethane, and more.

Small parts can usually be handled by a single cup, but people often combine multiple suction cups in a system to ensure a firm grip on objects.

To optimize for performance, make sure you choose the material most suitable for the environment it will be exposed to. Some materials can withstand exposure to UV, oil, water, solvents, and extreme heat or cold.

Of course, determining the total number of cups you use requires a holistic analysis of your system, including the vacuum source, cup type, size, shape, and material and surface of the objects to be handled.

Object surface porosity

The objects to be handled will necessarily affect your choice of a vacuum gripper. As a starting point, consider the following two categories of objects.

Porous surfaces include cardboard, unvarnished wood, fabric, styrofoam, and concrete. These require a strong vacuum flow to compensate for the loss of vacuum as air passes through the object.

Non-porous surfaces include glass, steel, aluminum, hard plastic, and varnished wood. With these, you can usually get away with a relatively lower vacuum flow and no -continuous negative pressure, because the cup can create a sealed vacuum with the object’s surface.

Getting started through testing

While the above factors are crucial to choosing your vacuum system, there are yet more considerations that will affect overall performance, like the distance between the vacuum source and cups, or the daisy chaining of cups. If you’re building your first vacuum gripper, it may seem challenging.

The best way to begin is to proceed through trial and error. Characterize the objects to be handled, and determine if you have access to a compressed air source. Then, select an off-the-shelf gripper that might work for your application or design a custom gripper if necessary.

For help finding the right vacuum system for your application? Talk to our experts today.