Finding the right type of robot arm for your industrial automation application is one of the early design choices that will have the biggest impact on the rest of your automation journey, including your return on investment. When selecting a robot arm for your application, close attention should be given to factors such as cycle time requirements, available floor space, programming skills, and safety.

We’ve listed four typical types of robot arms below and outlined what makes them uniquely suited for different applications. Note that this guide is meant to be a starting point, not an exhaustive overview. If you have any questions about your next robotic application, talk with our experts.

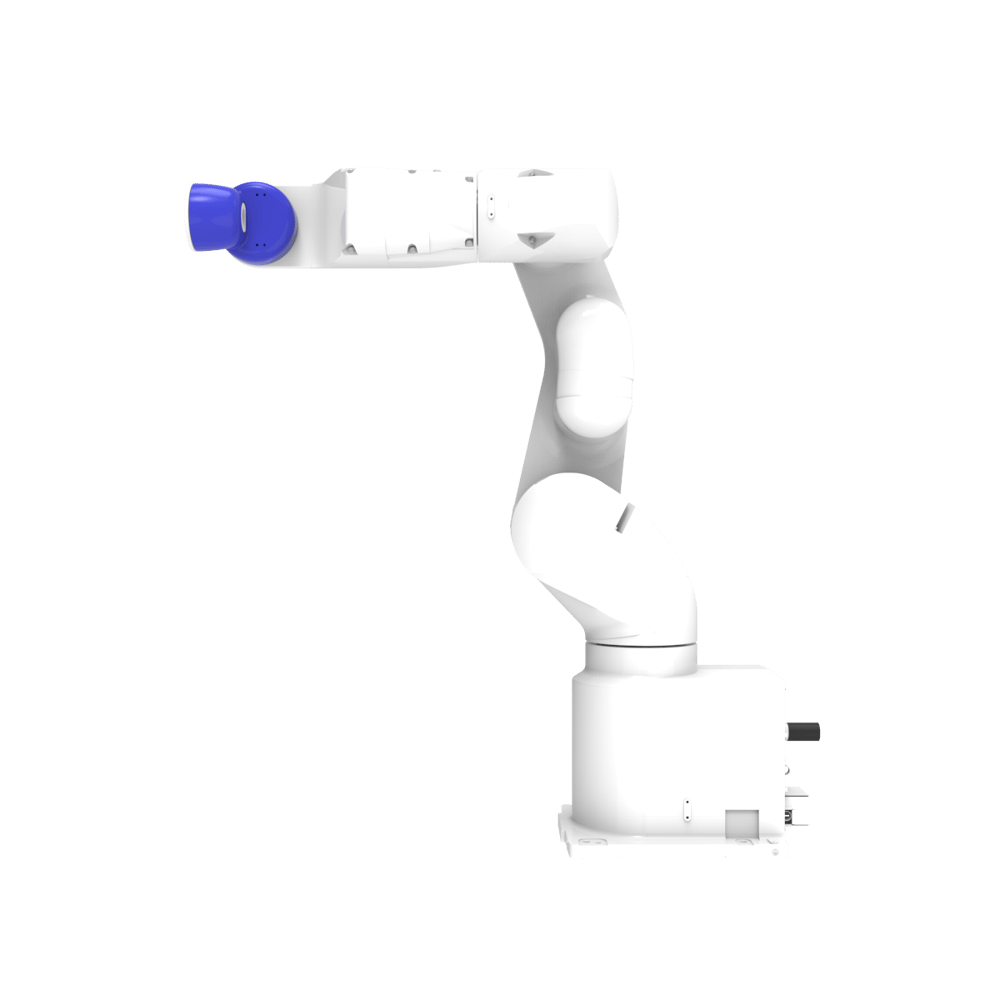

Small industrial robot

Small industrial robot example: Epson VT6L

With six degrees of freedom, these small industrial robots can move in the X, Y, and Z planes, and make roll, pitch, and yaw movements. Their flexibility makes them perfect for complex movements that simulate a human arm.

Application best suited for:

- Automating complex motions, such as simulating the movement of a human arm.

- Picking and placing parts at different angles (not just flat like SCARA robots).

- Relatively low-mix production, with infrequent part changeover.

- Floor space is large enough to accommodate significant guarding, larger safety scanners, and/or light curtains.

Key trade-offs for this type of robot:

- Integrating devices around the robot, like end-of-arm tools and safety devices, takes a lot of engineering labor.

- Programming and maintaining the robot is complex and requires highly trained specialists.

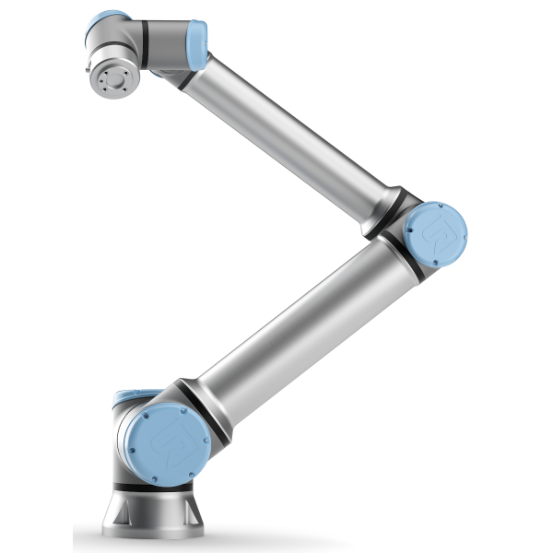

Collaborative robot

Cobot example: Universal Robots UR10e

Collaborative robots, or cobots, are six-axis robots created for working closely with humans. Equipped with sensing technologies, they stop automatically whenever they detect an obstacle—human or otherwise.

Application best suited for:

- Automating complex motions, such as simulating the movement of a human arm.

- Working with or near humans, especially if there isn’t enough floor space for guarding and other safety devices.

- High-mix production, with frequent part changeover and reprogramming.

- Relatively low cycle time requirements.

Key trade-offs for this type of robot:

- Slower speeds (required for safe human-robot collaboration) inevitably mean longer cycle times.

- Cobots alone don’t guarantee a robot cell is safe for humans; you must always conduct a full safety assessment. Be aware that using certain end-of-arm tools or handling dangerous parts can significantly impact safety requirements.

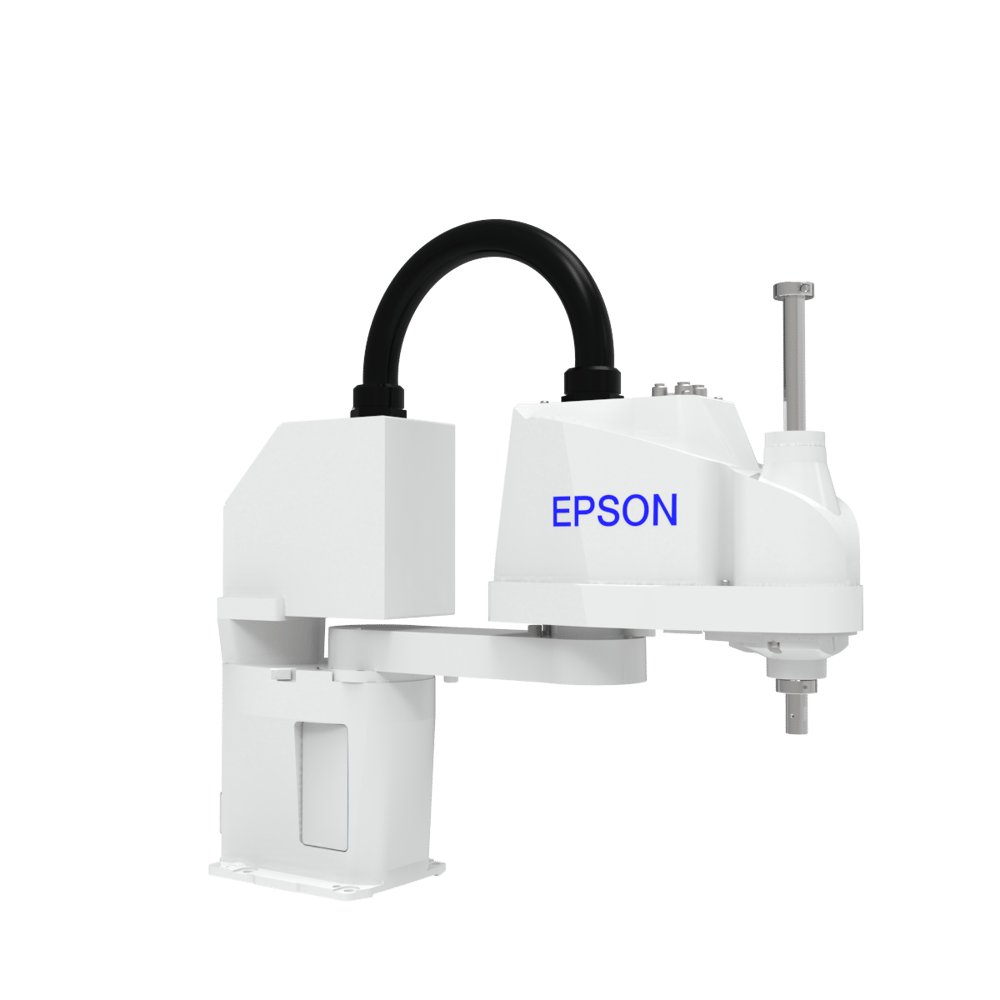

Scara robot

SCARA robot example: Epson T6-602S

4-axis SCARA robots are most commonly used for assembly operations where high speed and high accuracy are required. Selective articulated robot arms (or SCARA for short) are compliant in the X-Y axes and rigid in the Z-axis.

Application best suited for:

- Picking parts from flat surfaces, and placing them onto flat surfaces.

- Placing parts with high accuracy and repeatability.

- Short cycle times (60–70 ppm).

- Low-mix production, with infrequent part changeovers.

- Limited floor space and small robot cells.

Key trade-offs for this type of robot:

- Reach is limited, typically to around 450–650 mm.

- Payload is limited—typically less than 9 kg—because the payload is supported on an extended arm, which acts like a lever.

- Vision systems may be required to increase the flexibility of the application.

- Integration of safety devices is required.

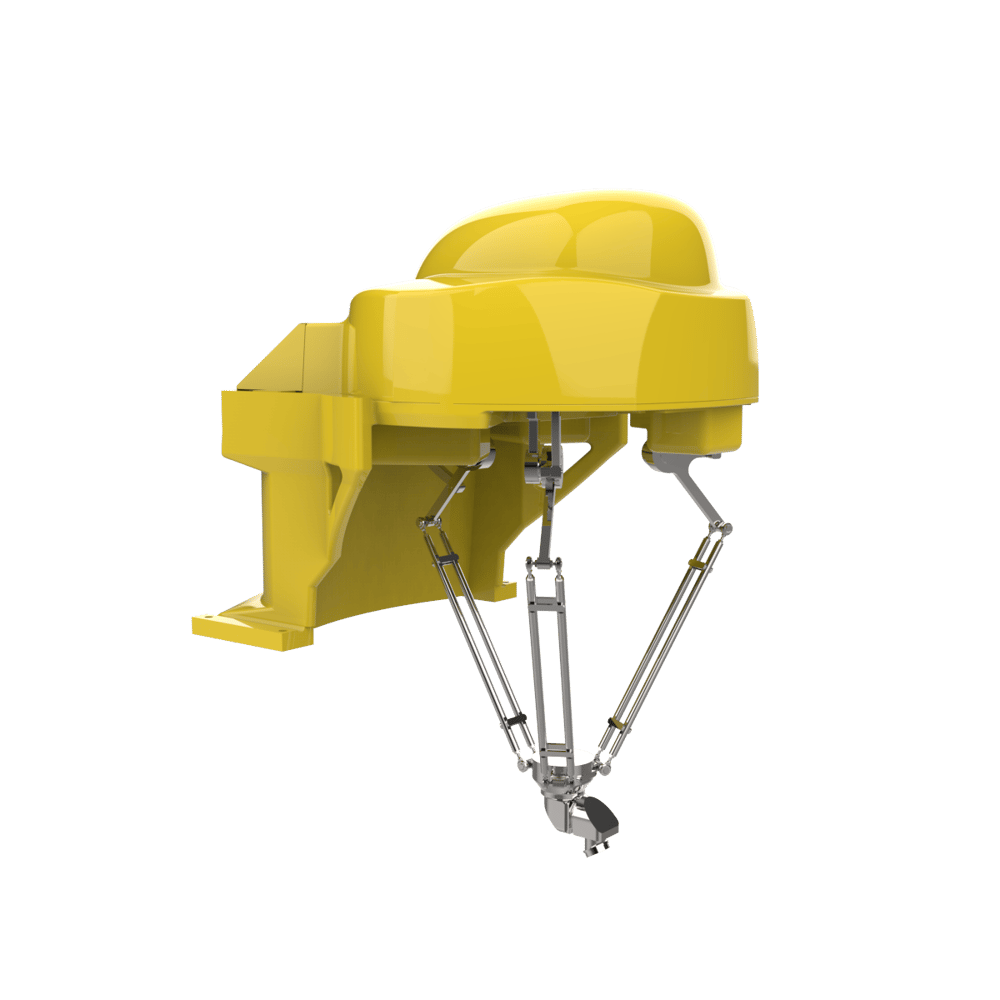

Delta robot

Delta robot example: FANUC M-1iA

Delta robots consist of three arms extending down from a central hub and connecting to a small tooling plate with an end effector. Combined with a vision system, they are typically used to pick and place small parts passing on conveyors placed below the robot.

Application best suited for:

- Very short cycle times (great than 100 ppm).

- Low-mix production, with infrequent part changeovers.

- Picking parts from conveyors.

- Placing parts without particularly good accuracy or repeatability.

- Limited floor space, because they’re usually mounted over the workspace.

Key trade-offs for this type of robot:

- Payload is very limited, typically less than 2 kg.

- Maintenance and repairs may be costly if frequent calibration is required.

Ready to get started? Search for “robot cell” in our public design library to explore designs or talk to one of our experts.