In the fast-paced and dynamic world of manufacturing, automation plays a pivotal role in improving palletizing processes. Special considerations are needed for manufacturers looking for palletizing robots for a wide variety of products. For example, you wouldn’t palletize a case of perishable items the same as fragile items. Luckily, automation can greatly improve efficiency, precision, and adaptability when handling diverse product types.

Continue reading to learn about different factors you should consider when building an end-of-line packaging solution.

Weight Distribution Optimization:

Automation allows for the programming of robotic systems to optimize weight distribution on production lines. These systems analyze the product’s weight to adjust placement and prevent imbalances during loading and unloading. This not only enhances the safety of the goods but also contributes to the longevity of the equipment.

Handling Fragile and High-Value Items:

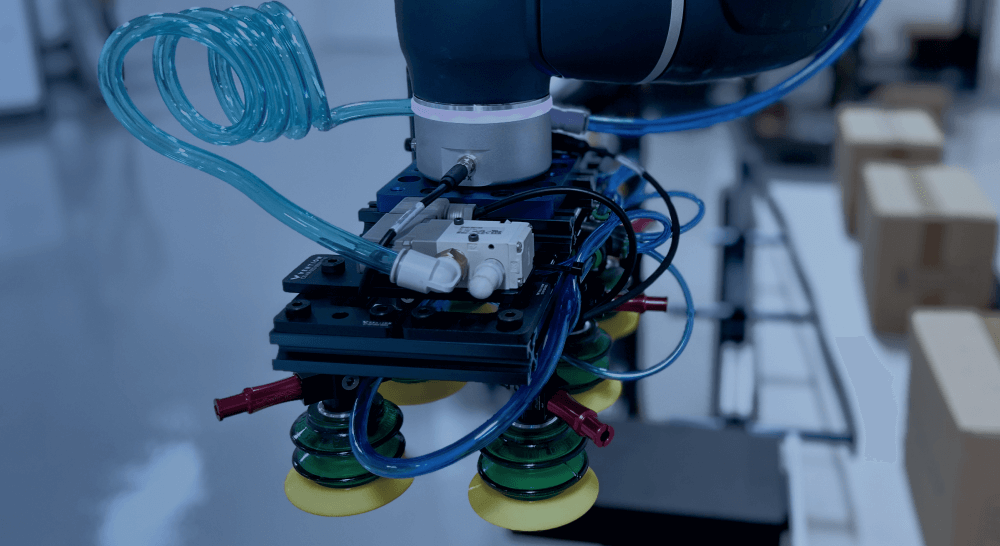

Precision is paramount when dealing with fragile, high-value items. Robotic arms and advanced end-of-arm tools provide the finesse needed to gently place delicate products on pallets with unparalleled accuracy. This minimizes the risk of breakage during palletizing and ensures the safe transport of these valuable items.

Temperature-Sensitive Products:

In industries where temperature control is crucial, such as pharmaceuticals and food processing, industrial robots can integrate seamlessly with refrigeration and insulation systems to keep perishable goods at the correct temperature.

Compliance and Traceability:

Automated systems help manufacturers comply with industry regulations by providing tracking and accountability in the packaging process. These systems can generate detailed reports through data logging and monitoring, demonstrating adherence to specific guidelines. This is particularly important in sectors with strict regulatory compliance, such as pharmaceuticals and chemicals.

Advanced Robotic Palletizing Systems:

Most modern automated palletizing systems can come equipped with advanced vision technology and machine learning algorithms. These systems can recognize and adapt to different boxes and types of products, ensuring their precise placement. Robotic palletizing is essential for productivity and efficiency in industries with a high mix of SKUs.

Conclusion:

As industries evolve and product diversity continues to expand, the role of robots in palletizing will become even more integral to achieving optimized supply chain operations. But don’t just take our word for it. Read real-life customer success stories to learn more about our palletizing solutions and the data-driven results for our customers.