Robotic Palletizing

What is a Robotic Palletizer?

A robotic palletizer is an automated palletizing system that uses a palletizing robot to pick, place, and stack boxes, buckets, or bags onto pallets in an array predefined stacking patterns. These palletizing robots streamline end-of-line packaging by increasing speed, consistency, and efficiency compared to manual palletizing. Utilizing a robotic arm equipped with various end-of-arm tools (EOATs), palletizing robot are the necessary successor to conventional palletizing methods. Palletizing robots are increasingly favored for their lower capital costs, versatility, and multitasking abilities.

What is a Collaborative Robot (Cobot)?

A collaborative robot, commonly known as a cobot, is an articulated robot arm with safety features, sensors, and force controls intended for direct human-robot interaction within a shared space. Cobots represent a significant advancement in industrial automation technology. Unlike traditional robotic systems, cobots are designed to work safely alongside human workers, blending robotic efficiency with human flexibility. They are equipped with advanced safety features like force-torque sensors and collision detection technology, ensuring a safe co-working environment.

Cobot palletizers stand out for their adaptability and ease of use. With modular components and intuitive interfaces, your palletizer can quickly be reconfigured and programmed for different tasks, making them ideal for varying production demands. This adaptability, combined with their safe and collaborative nature, positions cobot palletizers as a versatile and future-proof solution in automated palletizing.

What Does a Robotic Palletizer Do?

Robotic palletizers are advanced systems designed to automate the pallet-stacking process, enhancing both efficiency and accuracy. These machines utilize a unit load approach, where individual items, typically housed in boxes, are systematically arranged onto a pallet. This method streamlines handling multiple boxes at once, which is far more efficient than moving individual items separately.

At the heart of robotic palletizing is precision and consistency. Each box is carefully picked up by the robotic arm and accurately placed on a pallet in a predetermined arrangement. This process ensures stable and compact pallet loads, ready for storage or shipping. By automating this process, robotic palletizers significantly reduce the manual effort and time required for palletizing, while also minimizing the risk of errors and injuries associated with manual handling.

In essence, a robotic palletizer drastically improves the way products are prepared for distribution, offering a sophisticated solution that combines speed, precision, and reliability in the palletizing process. Let’s dive a little deeper into the core benefits of robotic palletizing:

Increased productivity

They eliminate the need for manual labor in unitizing products, lifting heavier loads, and performing tasks more efficiently. With the ability to operate continuously, they reduce bottlenecks in packaging lines.

Better product handling

Automated movements are pre-programmed to function without causing product damage and in patterns that optimize the stacking layout, making robotic palletizers less prone to errors and ensuring superior handling compared to manual methods.

Improved workplace safety

By automating tasks that pose physical risks, such as falling, slipping, and muscle strains, robotic palletizers contribute to a safer work environment and prevent potential injuries to workers.

Reduced operating costs

Investing in a robotic palletizer often yields positive results, with savings derived from increased throughput, reduced product wastage, and lower labor costs.

Robotic palletizers’ ability to serve multiple lines, versatility in pattern formation, and compact design make them a suitable choice for a variety of applications. They are categorized based on configuration and construction, including single in-line, palletizing-depalletizing, layer-forming, and mixed configuration types. The different types include cartesian/gantry and standard 7th axis palletizers, each offering unique ranges of motion and construction complexity.

How do Robotic Palletizers Work?

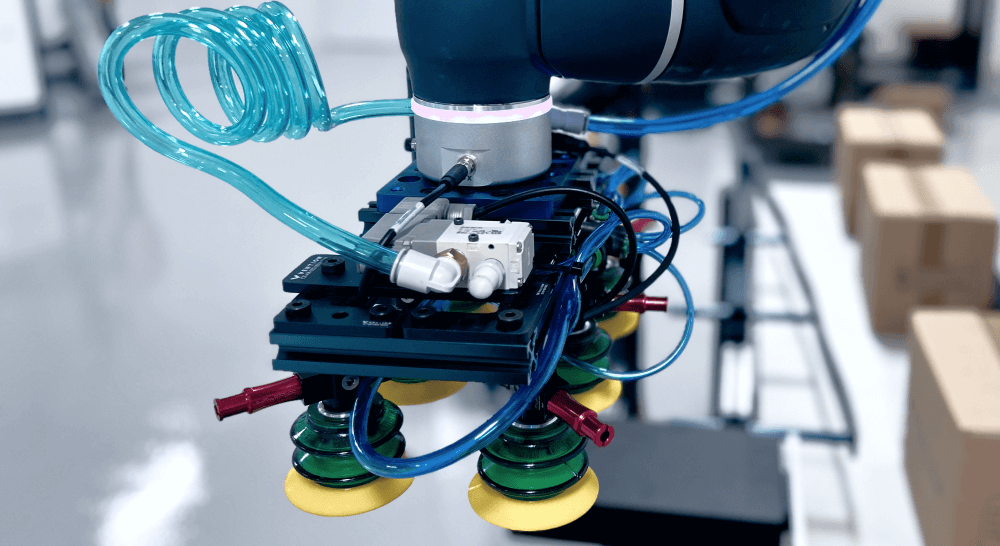

Robotic palletizers operate through a sophisticated blend of mechanical engineering, robotics, and software programming. A robotic arm, typically mounted on a stationary base, is at the heart of their operation, equipped with advanced sensors and an end-of-arm tool (EOAT). This tool can vary in design, including robotic palletizing grippers, vacuum systems, or clamps, depending on the specific application and type of products being handled.

The Process of Robotic Palletizing

The process of automated palletizing begins with the delivery of products to the robot cell, usually via an infeed conveyor system. Each product is identified and picked up by the robotic arm. The precision of these systems allows for the accurate placement of items on the pallet, adhering to a pre-programmed stacking pattern. This pattern is crucial for maximizing space utilization and ensuring the stability of the palletized load.

As the products are stacked, slip sheets or tier sheets may be incorporated between layers for additional stability or to meet specific packaging requirements. Once a complete layer is formed, the robotic arm stacks subsequent layers until the pallet is fully loaded. This methodical approach ensures consistent and efficient palletizing, far surpassing the capabilities of manual processes.

Advanced Features and Technologies

Modern robotic automated palletizers are embedded with sophisticated software and sensors that enable real-time adjustments during operation. This adaptability is particularly useful in handling a variety of product sizes, shapes, and weights. Some systems are equipped with machine vision technologies, allowing them to identify and orient products accurately, further enhancing their efficiency and reducing the likelihood of errors.

Integrating robotic automated palletizers with manufacturing execution systems and other automation components is another key aspect of their operation. This connectivity allows for seamless coordination between different production and packaging stages, optimizing the manufacturing process’s overall efficiency.

Now that we have delved into how robotic palletizers work, let’s explore the different types of machines. Different robotic palletizers are designed to cater to specific requirements and applications in the automation process, offering a range of capabilities and functionalities.

What are the Types of Robotic Palletizers?

Robotic palletizers, integral to modern manufacturing processes, are classified based on their configuration and construction, each designed to cater to specific operational needs. Let’s explore the various types of robotic palletizers.

Single In-Line Palletizer

The single in-line palletizer is the simplest and most common configuration. It involves a single robotic unit performing the palletizing function, sometimes with additional capabilities like slip sheet dispensing, pallet placing, and stretch wrapping. These palletizers can serve one or more palletizing lines with different product SKUs. Typically, they are equipped with articulated arms and custom-made EOATs. While offering high versatility, they tend to have a lower throughput compared to other configurations.

Palletizing-Depalletizing

This versatile type combines the functions of palletizing and depalletizing. Suitable for applications requiring the unloading of mixed pallets, these robots can sort goods according to product SKUs. Such a dual-function system is particularly beneficial in end-of-line processes like packaging and storage, as well as in the distribution and unloading of raw materials like empty bottles and boxes.

Layer-Forming Palletizer

Involving more than one robot, the layer-forming palletizer features an integrated system where each robot performs a specific task – one for layer assembly and another for stacking. This configuration enhances the overall throughput of the palletizing process. Some palletizer designs combine conventional and robotic palletizers, known as hybrid palletizers, where layer forming is done conventionally, and the robotic unit handles stacking.

Mixed Configuration Palletizer

Mixed configuration palletizers can handle a variety of products, unitizing them into a single pallet. These are typically top-tier models with sophisticated programs, custom EOATs, and sensors, capable of performing fine adjustments without reprogramming. They are most useful in high SKU packaging, storage, and distribution lines due to their versatility in handling diverse products.

Cartesian Palletizer

Cartesian palletizers feature an EOAT that moves in three directions (the Cartesian axes). They are relatively slow and suited for products with consistent weight and sizes, making them a cost-effective solution for simple applications with lower throughput requirements and higher payload.

Gantry Palletizer

Gantry palletizers have an EOAT mounted on a beam that moves along one axis, allowing horizontal plane movement. They are similar to Cartesian palletizers but are generally slower and can lift heavier loads due to their larger size and structure.

7th Axis Palletizers

7th axis palletizers, also known as linear palletizers, represent a significant advancement in robotic palletizing technology. Its key feature is the addition of a 7th axis of movement, which extends the functionality of the robotic arm. This extra axis primarily allows for the use of lower-cost robots or the integration within cobot frameworks, making high-end palletizing capabilities more accessible and cost-effective.

One of the principal benefits of the 7th axis is its ability to manage space constraints and accommodate unusual product placements. This is particularly valuable in environments with limited space or non-standard arrangements. Furthermore, the extended reach of the 7th axis is especially advantageous for applications requiring high-stacking capabilities. The ability to stack higher than traditional robotic systems maximizes storage and shipping efficiency and opens up new possibilities in warehouse and distribution center layouts.

How to Deploy a Robotic Palletizer?

Deploying a robotic palletizer requires a strategic approach, encompassing various aspects, from selecting the right equipment to ensuring its proper installation and maintenance. Let’s explore these critical steps:

Steps to Selecting the Right Robot or Cobot Palletizer

Assess Your Application

Before choosing a cobot palletizer, it’s essential to thoroughly assess your application requirements: Site Acceptance Tests (or Factory Acceptance Tests), product types, weight, size, and palletizing patterns. Your selected cobot should handle specific tasks efficiently.

Payload and Reach

Payload capacity and reach are critical specifications. Ensure the cobot can handle the weight of your products and reach desired palletizing positions. For instance, cobot palletizers typically handle products up to 25-30kg. If you need more, you may consider an industrial palletizer.

Cost and ROI

Cost transparency helps in understanding the impact of robot palletizer design choices on expenses, aiding in calculating expected ROI and staying within budget. Use an ROI calculator to easily calculate payback on a manufacturing project.

Safety Features

Safety is paramount. Opt for cobots with force-torque sensors, collision detection technology, and compatibility with external safety devices like area scanners and light curtains.

Programming and Ease of Use

User-friendly programming and integration with existing equipment are crucial.For Palletizers, a code-free application simplifies machine operation and training.

Flexibility and Scale

The Manufacturing Automation Platform (MAP) by Vention offers flexibility and scalability, allowing easy reconfiguration or expansion of your system as manufacturing needs evolve.

End-of-Arm Tooling (EOAT)

EOATs are essential for interaction with products and pallets. Vention offers a range of modular EOATs, such as grippers, vacuum systems, and clamps, for various products.

Support and Maintenance

Vention provides comprehensive support for installing, training, and maintaining your cobot palletizer, ensuring a seamless transition to automated manufacturing.

How to Deploy Easily with Vention, as Opposed to Traditional Deployment

Deploying with Vention simplifies the process compared to traditional methods. Our platform offers an intuitive and user-friendly experience, reducing the complexities typically associated with deployment. The combination of our modular design, easy integration, and robust support system ensures a smoother mastery of automated palletizing deployment.

Common Cobot Palletizing Mistakes and How to Avoid Them

As we have explored the various types of robotic palletizers, it’s equally crucial to understand how to effectively deploy these sophisticated machines. Proper robotic automated palletizer deployment not only maximizes their efficiency but also ensures they integrate seamlessly into your existing production environment. Like any new equipment purchase or installation, there are a few robotic palletizer mistakes to avoid that must be considered to ensure the project does not fail.

Lack of Proper Planning

A common pitfall in deploying robotic palletizers is inadequate planning. Thoroughly analyze your workflow, load characteristics, and overall system requirements, including the products’ dimensions and factory footprint.

Inadequate End-of-Arm Tooling (EOAT)

Selecting an unsuitable EOAT can significantly impact the efficiency of your operations. Opt for modular and adaptable tooling that caters to various product types and sizes.

Insufficient Training and Programming

Proper training and programming are vital for efficient operation. Utilize user-friendly, no-code programming environments like Vention’s MachineApps and ensure comprehensive training for your team.

Neglecting Safety Measures

Implement safety-rated sensors, protective barriers, and well-defined work zones to ensure safe operation alongside humans.

Ignoring Regular Maintenance

Regular maintenance is crucial for optimal performance. Establish a maintenance schedule and utilize 24/7 monitoring technologies.

Failure to Optimize Workflows

Integrating cobots into optimized workflows is essential for efficiency. Use intelligent software for pallet configurations and pattern adjustments.

Overlooking Communication and Connectivity

Ensure seamless integration into your facility’s communication network and use standardized protocols for smooth operation.

Understanding Payload and Reach Limits

Understand the specific payload and reach limits of your cobot to avoid overburdening and potential damage.

By addressing these common mistakes and implementing the suggested solutions, you can deploy a robotic palletizer that enhances productivity, safety, and overall operational efficiency in your manufacturing or packaging processes.

Having understood the common mistakes to avoid when deploying robotic palletizers, let’s now focus on the special factors to consider in palletizing.

Special Factors to Consider in Palletizing

To maximize the deployment of a robotic palletizer, certain special factors should be considered to enhance efficiency and compliance. Incorporating a robotic palletizer involves considerations beyond basic operation, focusing on optimizing performance and adherence to industry standards.

Weight Distribution Optimization

Robotic palletizers can be programmed for optimal weight distribution, adjusting placement to maintain balance and ensure safety during the palletizing process.

Handling Fragile and High-Value Items

For delicate and valuable items, the precision of robotic palletizers minimizes breakage risks, handling products gently and accurately.

Temperature-Sensitive Products

In sectors like pharmaceuticals and food, robotic palletizers can work with temperature control systems to maintain product quality and safety.

Compliance and Traceability

Robotic palletizing systems support regulatory compliance in industries like pharmaceuticals, offering detailed tracking and data logging for accountability.

Advanced Robotic Palletizing Systems

Modern systems are equipped with vision technology and machine learning, enabling them to adapt to various product types and ensure precise placement, especially crucial in industries with diverse SKUs.

These factors are vital in ensuring that your robotic palletizing system is efficient, compliant, and versatile enough to handle a range of product types and operational requirements.

Benefits of Robotic Palletizers

What Are the Benefits of Robotic Palletizers? The benefits of robotic palletizers include increased throughput capacity, enhancing operational efficiency, worker safety, end-of-line productivity, and stacking quality. Explore the key benefits below:

Advantages of Automating Palletizing

Streamlined Operations and Increased Efficiency

Automated palletizing ensures fast, accurate results, continuously handling large volumes of products and outperforming manual processes. This leads to faster production cycles, reduced lead times, and increased overall output.

Enhanced Safety and Reduced Labor Costs

By automating repetitive and physically demanding tasks, robotic palletizers reduce workplace injuries and reduce labor costs. This allows workers to focus on more value-added tasks.

Optimized Storage Space

Automated palletizing systems optimize space within warehouses and distribution centers. The robotic arms stack pallets more efficiently, maximizing vertical space, and ensuring denser, more stable pallet loads.

Flexibility

Modern palletizing processes are highly adaptable and can handle various product types, sizes, and packaging configurations. This flexibility allows businesses to quickly adjust to market demands without significant changes to their systems.

Cost Savings

Automating packaging operations leads to more efficient processes, reduced labor costs, and maximized storage space, resulting in a strong return on investment. Some manufacturers see ROI in as little as nine months.

Data-Driven Decision-Making

Automated systems equipped with sophisticated sensors and software provide real-time operational data, enabling analytics that offer insights into production efficiency and equipment performance.

Precision and Consistency

Unlike manual operations prone to errors, automated systems offer unparalleled precision and consistency, ensuring every pallet is evenly filled and products are delivered to customers faster.

How much does a Robotic Palletizer cost?

Palletizer robots and cobot palletizers can start at less than $100,000 and go up from there depending on needs. If a line includes heavy payloads, an industrial or cartesian palletizer is required, which can be more costly but highly effective. If a line includes lighter payloads, a cobot palletizer will be more cost-effective and just as efficient.

Delays in installation and unnecessary sunk costs can occur when sourcing peripheral equipment from multiple vendors. That’s one reason why manufacturers choose Vention. The Vention parts library includes 1,000+ modular components, all compatible and field-tested over tens of thousands of deployments. Having the peace of mind that everything will arrive exactly as it should when it should, and from a single vendor makes setup and deployment a breeze for manufacturers.

Leading Robot Arm Brands for Palletizing

FANUC: Known for their advanced robotic solutions, FANUC offers a range of palletizing robots known for high-speed precision and reliability, making them suitable for various industries. Their payloads range from cobots beginning at 5kg to industrial robots at 2,300kg. A Fanuc cobot palletizer price tag is usually around $100,000 but can either be less costly or more expensive depending on it’s the robot cell configuration, fixtures, in-feeds/automated conveyors, etc.

Universal Robots: A pioneer in collaborative robots, Universal Robots offers palletizing solutions that are user-friendly and highly adaptable, capable of working alongside human employees without safety guarding. Universal Robots price tags can also vary depending on robot cell configuration, equipment, and needs. The Universal Robots, price of a UR3e articulated robot arm is generally sold for 33,011 USD, while the Universal Robots, the UR20 price is around 62,990 USD.

Introducing the Next Generation of Palletizing

The Vention Rapid Series Palletizer represents the next generation of cobot palletizing. It stands out for its quick deployment, operational readiness in less than two weeks, and cost-effective design. Key features include a 5-day lead time, 2-day deployment, a 6-month payback period, payloads ranging from 7-15 kg, stack heights up to 77 inches, and a capacity of up to 13 boxes per minute.

The Rapid Series Palletizer is fully compatible with the best palletizing software on the market, MachineApps, which allows for easy, code-free pallet configuration and real-time simulation, making it user-friendly and efficient for operators.

In addition, Vention provides comprehensive support for the Rapid Series Palletizer, including on-site deployment, programmed SKUs, Remote Support, and training. This support system ensures reduced downtime, enhanced productivity, and optimized performance of the palletizer.

This innovative solution marks a significant leap in the field of end-of-line packaging. By replacing manual labor with this compact and easy-to-use system, manufacturers can achieve new productivity levels and unparalleled performance.

Best Practices for Palletizing in Your Workspace

With an understanding of the top robotic palletizers and their unique features, it’s crucial to delve into the best practices for implementing cobot palletizing in your workspace. These guidelines ensure you maximize this technology, enhancing efficiency and productivity.

Risk Assessment and Safety Protocols

Before deploying cobots for palletizing, conduct a thorough risk assessment to identify potential hazards. Establish clear safety guidelines, including restricted work zones and emergency stop mechanisms. Health and safety training for employees working with automation is crucial to minimize accidents and promote a safe work environment.

Selecting the Right Robot for Palletizing

Selecting the right cobot is vital. Consider payload capacity, reach, and speed to ensure it meets your palletizing needs. Cobots with advanced sensing capabilities adapt better to product variations, offering flexibility for future production changes.

Optimizing Gripper Technology

The gripper or EOAT is critical for efficient product handling. Different types of grippers, such as vacuum and soft grippers, cater to specific products. Regular calibration and maintenance of grippers are essential for consistent performance.

Intuitive Programming Interfaces

Utilize user-friendly programming interfaces to simplify cobot operation. Intuitive programming reduces reliance on specialized skills, making cobots accessible to a broader range of employees and lowering costs.

Integration with Existing Systems

Seamless integration with existing production lines is important for smooth material and information flow. Use standardized communication protocols like EtherNet/IP for effective data exchange between the cobot and other devices.

Continuous Remote Monitoring and Analytics

Implement continuous remote monitoring and analytics systems to optimize workflows and enhance efficiency. This approach provides real-time data on palletizing performance, enabling proactive maintenance and performance optimization.

Employee Training and Collaboration

Provide comprehensive training covering cobot operation, safety protocols, troubleshooting, and maintenance. Well-trained employees are key to maximizing the benefits of cobot palletizing.

Conclusion

If you or your company is considering the addition of a robotic palletizer to your operations, it’s essential to have expert guidance and support. This is where Vention steps in, offering a comprehensive solution to your automation needs. The team of experts at Vention is dedicated to providing guidance, ensuring you make informed decisions tailored to your specific requirements. Check out these robotic palletizing customer success stories about how Vention helped manufactures with robotic palletizing deployment.

From selecting the right palletizer, and deploying it efficiently, to understanding the best practices for optimal performance, Vention covers every aspect of the process. With a focus on customer support, we ensure that the transition to automated palletizing is smooth, hassle-free, and, most importantly, quick.

Vention’s expertise in supplying cutting-edge technology and our commitment to manufacturer success and satisfaction means that your journey toward implementing a robotic palletizer will be seamless and efficient. We provide everything you need to get your robotic palletizing system up and running in no time at all, allowing you to reap the benefits of automation without the typical complexities.

Talk to an expert today if you’d like to learn more about automating your end-of-line material handling/palletizing.