Robot arms, sometimes called collaborative robot arms (cobot arms), offer automation systems for manufacturers facing challenges such as high operational costs, inconsistent product quality, and workplace safety concerns. They automate labor-intensive and repetitive tasks with precision and speed, significantly reducing production time and labor costs.

Manufacturers have said that the best way to begin scoping the purchase and building of these robot arm automation cells and their end-of-arm tooling is by using a 3D CAD MachineBuilder, which is free to use and available on any web browser. Users can add and order cobot arms or industrial robot arms from top vendors such as FANUC and Universal Robots, as well as all of the fixtures, bases, and extrusions for its installation. If you need assistance with scoping your build, our application engineers are available to support and provide guidance.

Robot Arms in Manufacturing

Types Robot Arms in Manufacturing

Robot arms, defined as programmable mechanical devices that mimic human arm functions, are essentially the basis for industrial automation equipment and automated manufacturing processes. These processes include, but are not limited to:

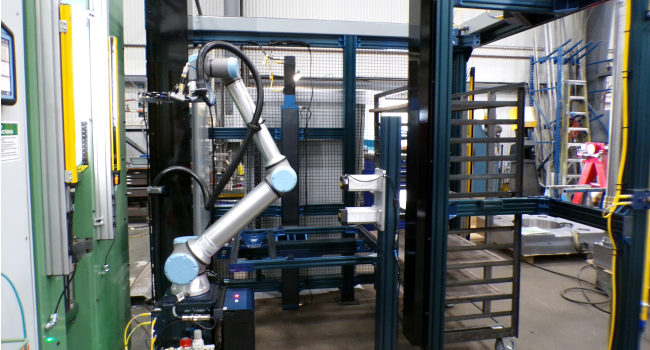

Pallet Stacking Robot Arms

Palletizing robot arm cells automate the stacking of products on pallets, significantly enhancing packaging consistency and speeding up production lines.

Woodworking and Metal Fabrication Robot Arms

Sanding and surface finishing robot arms ensure superior finishes by adapting to complex shapes, thus addressing common manufacturing challenges such as labor shortages and quality control.

Pick & Place Robot Arms

Pick & place robot arms are used in assembly lines or bin picking lines to move material easily from one place to another.

Machine Tending Robot Arms

Machine tending robot arms enhance production efficiency by automating the loading and unloading of CNC machines or Lathe machines, facilitating 24/7 operations without constant human oversight.

Welding Robot Arms

Welding robot arms are used in sectors demanding high-strength, precision welds such as aerospace and automotive manufacturing. Welding cobot arms maintain high production rates and more consistent quality.

Robot Arm End-of-Arm Tooling

Robot end-of-arm tools (EOATs) in industrial automation are the end effectors or tools attached to the end of a robotic arm that interact directly with parts and materials during the manufacturing process. These tools, such as industrial grippers and tool changers, are designed to perform various tasks, such as gripping, sanding, welding, assembling, and inspecting, depending on the specific requirements of the application.

EOATs are critical components in robotic systems because they enable robots to manipulate objects with precision and flexibility, thereby increasing efficiency and productivity in industrial settings. The design and selection of an EOAT depend on factors such as the type of material being handled, the weight of the objects, the speed of operation, and the complexity of the task.

Not only does MachineBuilder software provide real-time pricing and inventory for your industrial robotic arms, cobot arms, workstations, fixtures, extrusions, and more, but you can also select and order any of the following robot end-of-arm tools (EOAT) that your operation needs. Here are some of the most common robot EOATs and examples of use cases:

Robot Arm Electric & Pneumatic Finger Grippers

- Pick & Place Robot Arms: Handle components with precision across various automated assembly lines.

- Machine Tending Robotic Arms: Securely grip and manipulate parts for automated loading and unloading with 2-finger or 3-finger grippers.

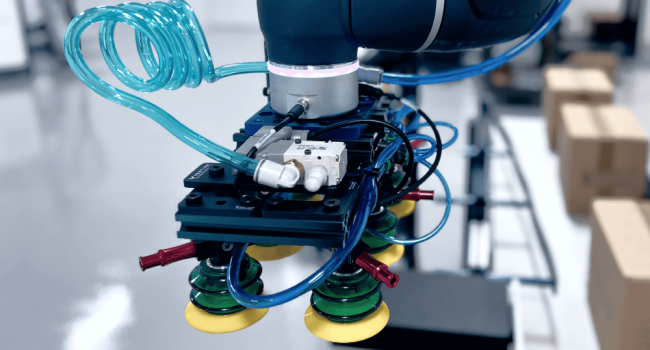

Robot Arm Vacuum Grippers

- Material Handling Robot Arms: Robot arm vacuum grippers help efficiently sort, assemble, and load items with smooth surfaces.

- Pick & Place Robot Arms: Vacuum gripper end effectors provide secure handling for a variety of components.

- Palletizing Robot Cells: Allow pick up and pallet placement of different package shapes and sizes in automated palletizing processes.

Robot Arm Tool Changers

- Palletizing Robot Cells: Allow quick adaptation to different package shapes and sizes in packaging processes.

- Machine Tending Robotic Arms: Facilitate seamless tool swapping for diverse machining tasks.

Robot Arm Sanders

- Sanding and Surfacing Robot Arms: Enhance capabilities for detailed woodworking and metal fabrication tasks by automating sanding and surface finishing.

Robot Arm Dispensing Kits

- Electronics and Automotive Wiring: Dispensers for precise wire dispensing in circuit assembly and automotive wiring harness fabrication.

- Medical and Pharmaceuticals: Syringe kits for precise dispensing in medical and pharmaceutical industries for various applications.

- Sealing and Bonding: Cartridge kits and two-part cartridges for reliable dispensing of sealants, adhesives, and two-component materials in aerospace and automotive manufacturing.

Robot Arms Prices

FANUC Robot Prices

Known for their advanced robotic solutions, FANUC offers a range of palletizing robots known for high-speed precision and reliability, making them suitable for various industries. Their payloads range from cobots beginning at 5kg to industrial robots at 2,300kg. Fanuc robots prices can vary depending on robot cell configuration, equipment, and requirements. The FANUC CRX, CRX-5iA, articulated robot arms are generally sold for 43k USD, while the FANUC CRX, CRX-25iA is sold for 61k USD.

Universal Robots Robot Prices

A pioneer in collaborative robots, Universal Robots offers palletizing solutions that are user-friendly and highly adaptable, capable of working alongside human employees without safety guarding. Universal Robots price tags can also vary depending on robot cell configuration, equipment, and needs. The Universal Robots, UR3e articulated robot arms are generally sold for 30k USD, while the Universal Robots, UR20 is sold for 60k USD.