To democratize industrial automation, knowledge sharing is important to drive innovation and develop the next generation of industrial automation practitioners.

In 2023, Vention founded our Knowledge Group series to highlight different industry leaders and their innovative automated solutions. So far, we have hosted Knowledge Groups virtually and in person on various topics, from press brake tending to robotic vision inspection and more.

Vention’s latest session featured Karl Ericsson from SE Automation. Hosted during Automatica 2023 in Munich, Germany, Karl presented their groundbreaking robotic grinding solution leveraging the combined power of Vention and Universal Robots.

For those interested in automated solutions, we have recapped the Knowledge Group—read on for highlights from the presentation.

What is SE Automation?

Svenska Elektrod (SE) Automation, founded in 1981, emerged in response to the challenges confronted by the Swedish manufacturing industry due to the widespread outsourcing of production to Asia and Eastern Europe. Instead of following the trend of outsourcing, SE Automation aimed to empower the local Swedish market by introducing collaborative robots to automate manual processes. Their ultimate goal was to enhance cost-effectiveness while significantly improving the environment for manufacturers.

What is SE Automation’s focus and solution?

SE Automation is a Vention Automation Partner, Certified System Integrator, and Authorized Training Partner for Universal Robots. They primarily serve the Swedish manufacturing industry and specialize in delivering solutions for automated welding

and grinding tasks. They aim to help the industry automate tedious, dirty, and often dangerous tasks by implementing cobots in all areas.

Why does SE Automation partner with Vention?

Partnering with Vention allowed them to provide world-class solutions to customers with a remarkably short lead time. By utilizing Vention’s Manufacturing Automation Platform (MAP), SE Automation significantly accelerates their time to market and quoting process as they no longer need to maintain extrusion inventory or handle

in-house cutting or kitting. They have access to dedicated technical support for any inquiries, which is an invaluable resource for their team. Furthermore, it allowed them to work with extrusion profiles specifically engineered for robotics and dynamic loads.

How does SE Automation leverage Vention?

SE Automation utilizes the full capabilities of the Vention’s MAP. Through our

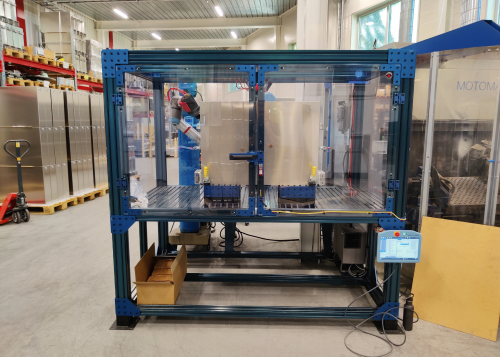

web-based platform, they can obtain custom designs using MachineBuilder, simulate and perform cobot reach study analysis using MachineLogic, and receive instant quotes, and place orders in MachinePortal. SE Automation has utilized MAP to build and order custom equipment, including UR cobot bases, UR mobile carts, cobot testing tables, and fully enclosed grinding cells.

What were the session’s key takeaways?

Karl spoke to Automatica attendees about his robotic grinding solution, CoboGrind, which features:

- A custom-designed Vention cabinet

- UR10e cobot arm

- Schunk MFT-390 spindle with axial compensation

- Built-in cycle counter for brush replacement and program adjustment

To create CoboGrind, Karl chose the Universal Robots UR10e cobot arm. With sensors in all 6-axes, the possibility to “free drive,” programmable safety fencing, a force sensor in the nose, digital I/O communication, and more, this medium-sized, versatile cobot is ideal for the smooth movements required for grinding.

To program the cobot, Karl explained the pros and cons of different methods, including force compliance, 3D vision path planning, and force-torque technology. The resulting solution has a cycle time of just under six minutes, resulting in increased productivity, fewer workplace injuries, and happier employees who are moved to higher-value tasks.

Interested in attending our next Knowledge Group?

Knowledge Groups are hosted on a bi-monthly basis, either virtually or in person.

The topic and the speaker are always changing to bring innovative perspectives and knowledge about automating some of manufacturing’s greatest challenges.

The date for our next Knowledge Group will be announced soon.

Follow our LinkedIn and Instagram to stay up to date on Vention.