To democratize industrial automation, knowledge sharing is important to drive innovation and develop the next generation of industrial automation practitioners. In 2023, Vention founded our Knowledge Group series to highlight different industry leaders and their innovative automated solutions. So far, we have hosted Knowledge Groups virtually and in person on various topics, from press brake tending to robotic vision inspection and more.

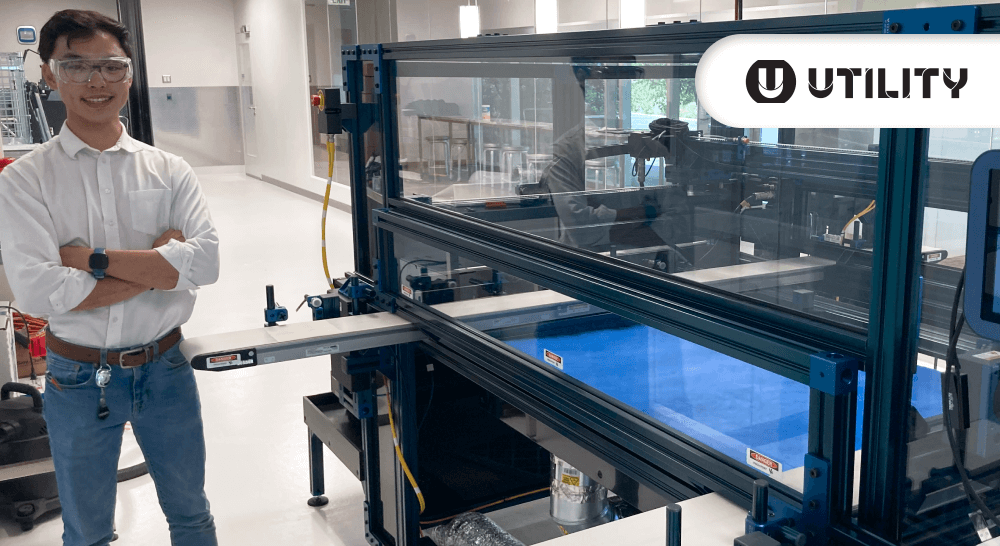

Vention’s latest session featured Jesse Li from Utility Global. Hosted virtually, Jesse presented his custom Vention gantry solution designed and programmed on our Manufacturing Automation Platform.

For those interested in automated solutions, we have recapped the Knowledge Group with Jesse—read on for highlights from the presentation.

What is Utility Global?

Utility Global, established in 2018, was created to bring forth sustainable business solutions, enabling an affordable energy transition to a low-carbon world. Their main mission is to convert and concentrate valuable streams of hydrogen and syngas from waste gases. With over 40 employees, they closed their Series B funding last year and expanded their headquarters in Houston in 2023.

What is Utility Global’s focus and solution?

Their scientists have developed a cleaner and more efficient alternative to other energy and carbon-intensive methods. They solve many decarbonization challenges for hard-to-abate industries while complementing existing operations. Utility offers several products developed for a range of applications in steel, refining, petrochem, and transportation. Their highly flexible products effectively and efficiently convert a variety of gas inputs into valuable, high-purity gas streams for reuse as energy, feedstock, or fuel.

Why did Utility Global partner with Vention?

As Utility Global experienced rapid growth, the demand for their solution surged. Realizing that manufacturing critical components one at a time was inefficient for meeting this heightened demand, they began exploring automated solutions. However, conventional custom machine builders were deemed out of budget with lengthy lead times. In their search, Utility Global came across Vention, where they discovered that they could harness our Manufacturing Automation Platform (MAP) to independently design and program a custom machine using our 3D CAD software, MachineBuilder, and our code-free programming environment, MachineLogic. Not only did Vention align with Utility’s budget and timeline requirements, but we also ensured modularity, providing a future-proofed system that could scale in line with their increasing demand.

What was the presented solution?

Jesse Li, Project Engineer at Utility Global, unveiled his custom gantry system—a spraying system equipped with conveyors, pneumatic actuated entry and exit doors, pneumatic locating features for parts, and a 2-axis gantry for precise part spraying. Jesse designed this customized solution within MachineBuilder, with dedicated design support from our application engineers.

How was the solution programmed?

Instead of hiring an expensive programming expert or grappling with complex coding, Jesse turned to MachineLogic. Within a single programming environment, he successfully programmed his entire gantry system without writing a single line of code.

“I used MachineLogic’s code-free interface and was able to program my entire machine in under 30 minutes.” - Jesse Li, Utility Global

What were the key takeaways from the session?

Similar to many other industrial automation projects, it is advisable to create a minimum viable prototype for testing and validation before proceeding with subsequent equipment orders. After Vention and Jesse collaborated to build the first prototype, we managed to reduce the machine’s footprint by 40% and optimize its design while maintaining the desired performance level. Additionally, Jesse enlisted the assistance of a team of students from Vanderbilt University to assemble the equipment, outsourcing a straightforward task while empowering future engineers with firsthand experience with industrial equipment.

Are you interested in attending our upcoming Knowledge Groups?

Our Knowledge Groups are held bi-monthly, either virtually or in person. The topics and speakers continually change to provide fresh perspectives and insights into automating some of the most significant challenges in manufacturing.

Stay tuned for the announcement of the date for our next Knowledge Group by following our LinkedIn and Instagram accounts to stay up-to-date with Vention.