In this article, we’ll see how Vention created four very different robotic applications for four very different companies:

- A laser-tending robot for Cretex, a manufacturer of medical devices

- A multi-robot system for Automata, a provider of medical lab automation

- A palletizing cobot for Keter, a plastics manufacturer

- A precise, heavy-duty gantry system for Trajekt, a manufacturer of baseball-pitching robots

Cost-saving design software

Cretex manufactures medical devices and has used Vention for various applications including vision inspection carts, automated packaging systems, and CNC machine tending.

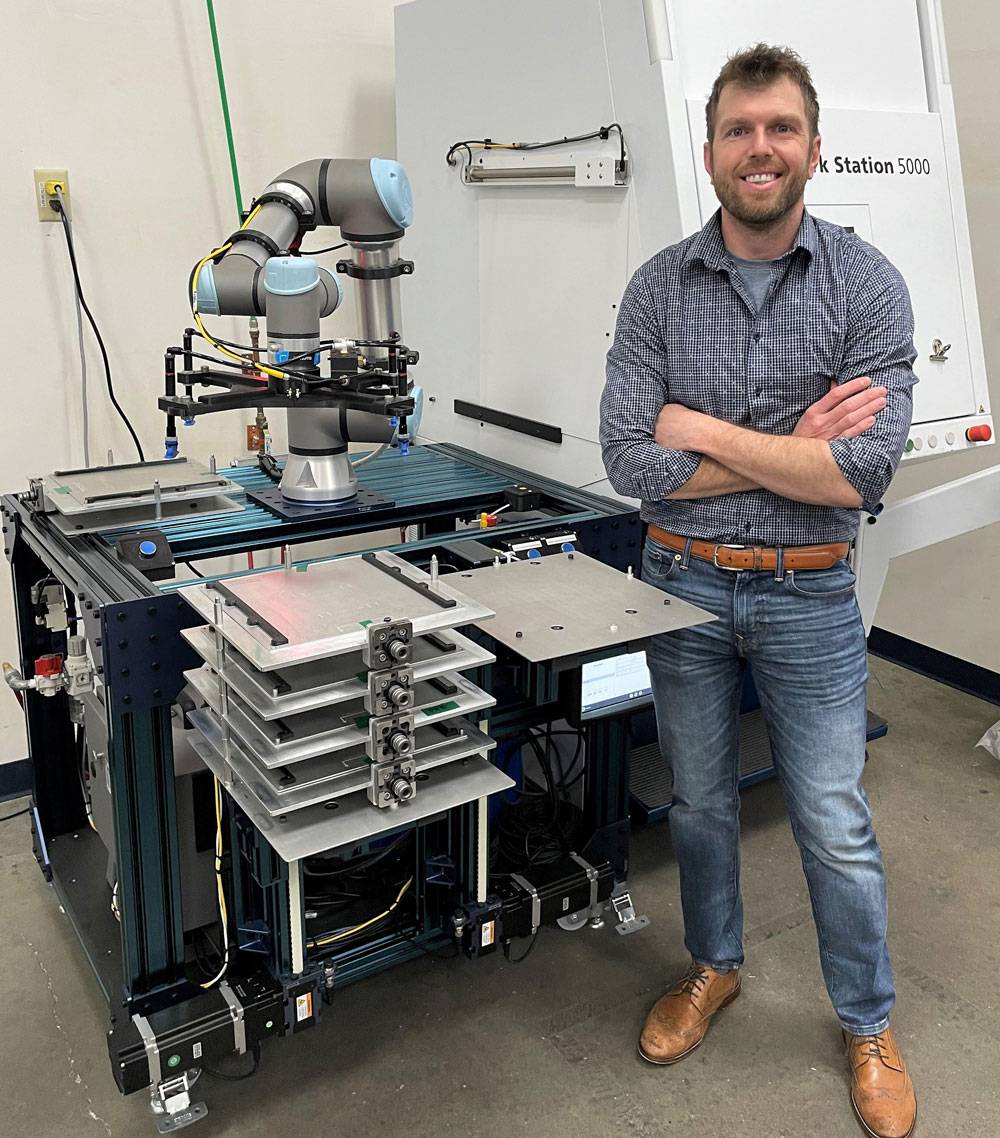

In early 2021, Scott Wisniewski, Automation Development Manager at Cretex, wanted to increase the efficiency of a system that lasers medical parts.

“I sketched the work cell and used Vention’s free software to design the framework for my robot. Designing was about a week’s worth of work.” Wisniewski says that if he’d designed the robot cell in different CAD software, it would have taken him three times as long. In Vention’s MachineBuilder, the components are modular. Wisniewski says this speeds things up considerably compared to other CAD software, which requires each component to be designed from scratch.

The time savings mean substantial cost savings. “Including my labour to design and set it up, the system from Vention cost $70,000,” Wisniewski says. “If we’d had an integrator build the same robot, it would have cost at least double.”

The robot has been very successful for Cretex. When an operator lasered the parts, they were running 45 parts per hour. The robot’s current run rate is 130-150 parts per hour, and Wisniewski says it has the capacity to do much more when needed.

Image: Scott Wisniewski, Automation Development Manager at Cretex, with one of their robot cells

Effective collaboration

Automata helps medical laboratories automate their processes. The company has developed a proprietary lab robot, which they integrate into automated systems for their clients. A Britain National Health Service hospital needed a robotic system to improve its COVID-testing throughput rate. NHS budgets are approved every six months, so timelines on their projects can be tight. The pandemic added even more urgency. Instead of designing the complex robotic system by himself, Automata’s Applications Engineer, Axel Daian, reached out to Vention to help with the design.

“A week and a half before we were planning to pitch a solution to the NHS, I called Vention. We needed 20 robots and 20 liquid handlers, on four lines, all with conveyors and gates, all enclosed,” Daian explains. “Within a week, we had a design to show the NHS.”

The Automata engineering team was skeptical about ordering from Vention because extruded aluminum is typically more expensive than welding parts together. “When they saw how quickly the kit was assembled, they immediately changed their minds,” Daian says. “In the end, compared to our engineers spending time measuring and cutting metal, getting it wrong, and cutting it again — Vention is actually less expensive.”

Vention’s software made collaboration easy, Daian says. After deploying the robots, when he wanted to make a change, Daian contacted the Vention designer. Because both parties were working from the same 3D model, it was easy to talk about how to adjust it and decide what additional parts were needed. The model was simple to update, costs were automatically included, and Vention shipped the necessary parts.

Without the 3D model, it would be harder to keep track of design changes, Daian says. The digital model serves as an up-to-date record, “so when you order again, you know you’re ordering the right version.”

The system was designed to accommodate a 5x increase in productivity with improved accuracy and tracking, all within the same footprint as before.

Affordable turnkey solution

Keter was having trouble recruiting labor at their Ontario plastics manufacturing plant. By early 2021, COVID was worsening the situation. Taking cartons from a conveyor and stacking them onto pallets is dull, repetitive work — an ideal task to automate. Automation would also enable Keter to relocate some of their packing employees to higher-value tasks, such as inspection and troubleshooting.

“We’d used Vention on five previous robots, and I wanted to see their turnkey capabilities. I obtained a quote from another distributor, but it wouldn’t have been turnkey. There was virtually no difference between the two quotes,” says Garry Etchells, the Continuous Improvement Manager at Keter. “Because the quotes were so similar, it was as though the assembly, commissioning, and training I got from Vention were free. And this solution took a huge amount of work off my shoulders.”

Image: Garry Etchells, Continuous Improvement Manager at Keter, with one of their cobot palletizers

Keter’s needs were fairly complex. They have a dual infeed/dual outfeed palletizing line, handling many types of products. One line handles smaller storage totes (6 to 30 liters) and the other handles larger items that are up to a meter tall. Both lines pack variable numbers of items per carton, with a wide range of possible weights.

Etchells gave Vention the dimensions and weights of all the products and cartons, the palletizing configurations, and the throughput rates. With this information, Vention performed a simulation-based capability study. “Within a couple of weeks they told us it was feasible and gave us a quote,” Etchells says.

Etchells sent product samples to Vention, illustrating the extremes of weight and size. Via webcam, he watched Vention demonstrate the equipment with all the product combinations so he could make sure Keter’s requirements were met.

After Keter received the equipment, Vention’s integration specialist did most of the installation and commissioning. Etchells and a colleague spent half a day training with the cobot and the software. They then showed employees who’d previously been stacking boxes what to do when there’s an unexpected problem. “They found it really easy, as there are only a couple of things to check, and a couple of button presses to get it running again,” Etchells says.

**Keter’s new cobot can process up to 30 pallets an hour, and they operate 24 hours a day. The system saves them about $6000 per week on labour, and their payback period is six to twelve months of normal operations.**

Etchells says that on all six projects Keter’s done with Vention the ROI is less than a year. “If you run a 24/7 operation, it’s absolutely doable to see a return on investment within a year.”

Superior customer support

Ordinary baseball pitching machines have only 3 to 5 degrees of freedom. This isn’t nearly good enough for Trajekt’s clients: Major League Baseball clubs. To replicate human pitching, Trajekt designed a complex machine with 12 degrees of freedom, including a gantry system to move their robot — which weighs hundreds of pounds — up and down and left to right with high precision and repeatable accuracy.

Trajekt optimized the novel aspects of replicating a human pitcher and then used Vention’s software to design the gantry system and associated controller. Using this off-the-shelf, integrated solution simplified and shortened the overall design process.

“If we’d gone with another supplier, we would have had to reinvent the wheel and design our own controller,” explains Joshua Pope, Trajekt’s Co-Founder and President. “It saved lots of time to use the pre-programmed controller Vention included, and not have to write our own code library from scratch.”

Pope describes Vention as “the last mile of pitcher replication that enabled us to get very accurate release positions for the robot.”

It’s crucial that Trajekt is able to meet its contractual uptime obligations, and Pope is pleased with Vention’s customer service. “When we had some debugging to do, Vention was very responsive with resolving issues or finding the resources we needed to resolve them ourselves. They have excellent attention to detail and are clearly committed to their customers’ success.”

Image: Trajekt’s precise, heavy-duty gantry system

Conclusion

These four companies made use of Vention’s services in different ways to build robotic systems that vary widely in function, complexity, and scale.

The self-serve option worked well for Cretex, where Wisniewski has prior experience with robots. However, if a small manufacturer is doing their first foray into automation, machine tending, or some other machining application, Etchells says “the turnkey option was easy enough that it would definitely work for them, especially with on-site support.”

Approved by: Scott Wisniewski at Cretex, Axel Daian at Automata, Garry Etchells at Keter, and Joshua Pope at Trajekt

March 2022