In the fast-paced world of manufacturing and logistics, optimizing processes is key to staying competitive. Efficiency in palletizing has greatly improved with the use of cobots, or collaborative robots, in automation. This guide explains palletizing basics, cobot palletizer benefits, and how Vention’s solutions can boost your automated palletizing game.

The Fundamentals of Cobot Palletizing

Palletizing is strategically stacking products on pallets for storage, transportation, or distribution. This seemingly simple process involves careful consideration of weight distribution, stability, and spatial efficiency. Manual palletizing can be time-consuming, prone to errors, and dangerous for employees. Introducing automation has a proven impact on the well-being of workers, so why hesitate to implement cobot palletizing?

Cobots, or collaborative robots, work alongside human operators to enhance productivity and efficiency. With automated palletizing, collaborative robots offer enhanced flexibility and adaptability. Easily program them to handle various products, sizes, and weights, making them ideal for a dynamic manufacturing environment.

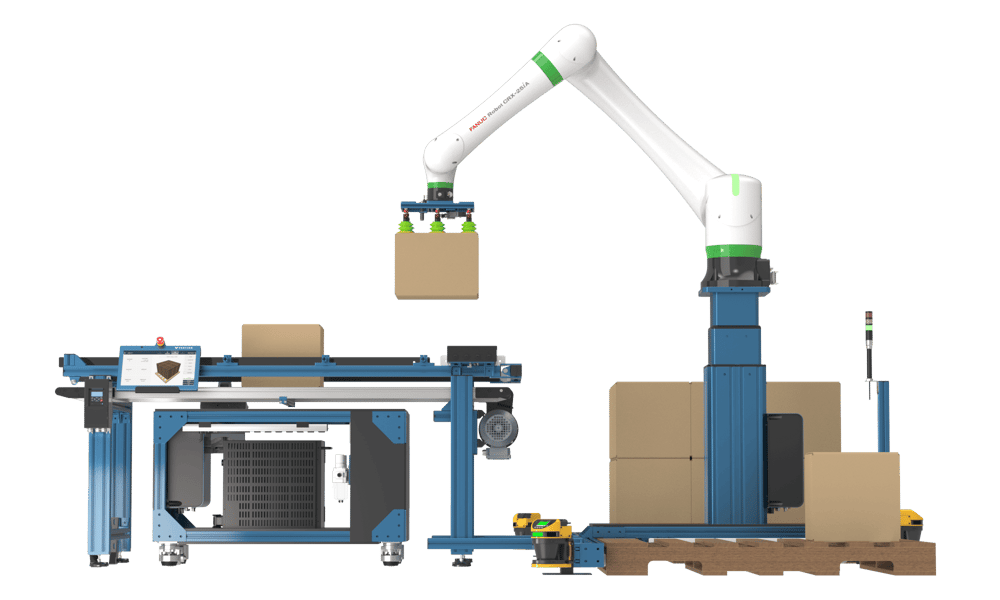

Along with cobot palletizers, industrial robot palletizers are another option for manufacturers looking to automate palletizing. This solution is the most effective solution for your heavier payload needs, with a max payload of 140kg. Requiring less technical integration and operation expertise, this turn-key, scalable solution helps you overcome labor shortages and production efficiency shortfalls.

Experience the following advantages:

- Increased productivity: Work in high-volume environments tirelessly without fatigue, significantly increasing the speed and consistency of the palletizing process.

- Enhanced safety: Reduce workplace accidents by operating alongside human workers on assembly lines using built-in sensors and safety features.

- Flexibility and adaptability: Easily reprogrammable to adapt to changes in production requirements, making the cobot palletizer a versatile solution for various industries.

- Space optimization: Maximize floor space utilization in your facility by operating in confined spaces.

Palletizing Cobots by Vention

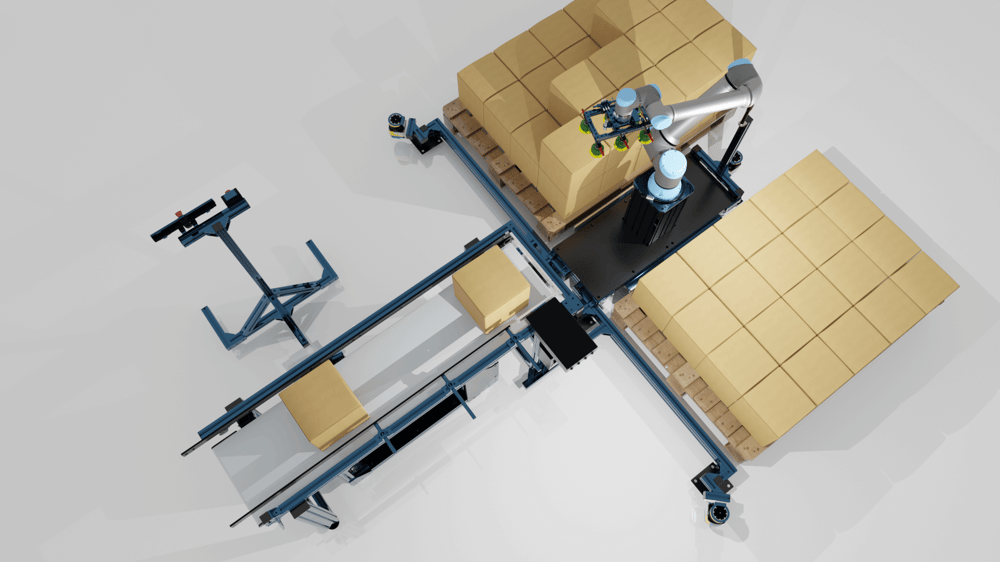

As a leader in manufacturing automation solutions, Vention offers cobot palletizer solutions designed to seamlessly integrate into your existing production line. The Vention Cobot Palletizer combines precision engineering with user-friendly programming, making it the ideal solution for newcomers and experienced automation practitioners alike.

Key features of Vention’s Cobot Palletizers:

Plug & play integration: Easily integrate the cobot palletizer into your workflow with minimal disruption. With a comprehensive hardware library of 1,000+ plug & play components, you can eliminate compatibility errors with Vention.

Intuitive programming: Vention’s user-friendly programming interface, MachineLogic, makes it easy for those of all skill levels to program the cobot using either our no-code or Python programming environment. The Vention Palletizer MachineApp allows you to configure and operate your machine with its operator-friendly interface for fast SKU changeovers and adaptations.

Remote monitoring: Keep an eye on your robotic automated palletizing process from anywhere with Vention’s remote monitoring solution, MachineAnalytics. Accessible through your Vention dashboard, access real-time insights and historical data on your machine’s health and performance anytime, anywhere. For a 24/7 view of your palletizer, access RemoteView, to see your machine running in real-time.

Scalability: Whether you’re a small business or a large-scale manufacturer, Vention’s cobot palletizer can scale to meet your evolving needs. The modular components and robot-agnostic software allow for an easy and straightforward process. Once you deploy one cobot palletizer cell, you are able to do it again at a larger scale as your business grows.

Quick payback: With any robotic palletizing solution from Vention, you can expect to see return on investment (ROI) in nine months or less, allowing you to accelerate your automation roadmap. Quickly calculate your project’s ROI using the Vention industrial automation ROI calculator.

Automation, Simplified with Vention

Mastering the basics of cobot palletizing automation is a critical step toward improving efficiency in your manufacturing process. With Vention’s solutions, you not only embrace the advantages of automation but also position your business at the forefront of technological innovation.

Are you prepared to begin your automated palletizing journey? Follow these eight steps to selecting the right cobot palletizer. Ready to chat with our team? Talk to an expert today.