In today’s fast-paced manufacturing landscape, staying competitive means embracing innovation and efficiency. One key advancement gaining traction in industrial automation is the addition of a robot 7th axis to factory floors.

What is a Robot 7th Axis?

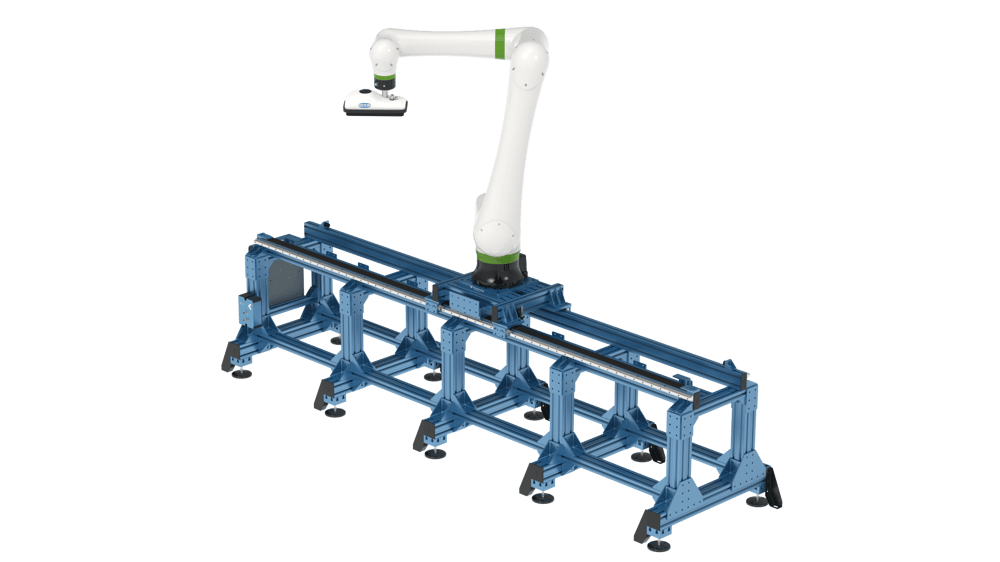

A robot 7th axis, also known as a “range extender,” is the addition of a linear motion axis for a robotic system or machine to move along. Combining a linear actuator with a robot arm (which typically only has 6 degrees of freedom) creates a system with a 7th axis. The purpose is to extend a robot’s reach or working range, allowing it to perform tasks outside of its standard work envelope.

Benefits of a Robot 7th Axis

- Increased Productivity: By integrating a 7th axis, you enable your robotic systems to cover larger work areas without relocating the entire setup. It also gives extended reach to smaller robots. This leads to increased throughput and production efficiency, as robots can handle a wider range of tasks without interruptions.

- Enhanced Flexibility: A 7th axis provides greater flexibility in your manufacturing process. It can move items or tools in different angles and positions, making it easier to complete tasks with different products.

- Optimal Space Usage: With the ability to reach over a more extensive workspace, a range extender allows you to make the most of your factory’s available floor space. This is especially beneficial in crowded manufacturing environments where efficient space usage is crucial.

- Reduced Downtime: Minimize downtime and changeover times by using a range extender for tasks like tool swapping, quality inspections, or parts feeding. The expanded range of the robot enables the completion of multiple tasks in one setup.

- Cost Savings: In the long run, investing in a 7th axis for robots can lead to significant cost savings for your production line. Increasing the reach of the robot often removes the need to buy a 2nd robot to execute similar tasks in a nearby location. The enhanced efficiency, reduced labor requirements, and lower maintenance costs can contribute to a more cost-effective manufacturing process.

Exploring Vention’s Robot 7th Axis solution

With Vention, adding a 7th axis to your factory floor is a smart investment in efficiency and productivity. It enables your manufacturing process to reach new levels, ultimately leading to cost savings and a competitive edge in the ever-evolving industry landscape.

On the Vention Manufacturing Automation Platform, we offer four configurations that can be tailored to meet individual needs:

- Floor-mounted / Base-installed / Ground-level 7th Axis: Best for increasing horizontal reach from 0.4 m to over 3 m.

- Overhead / Ceiling-mounted / Suspended / Elevated 7th Axis: Best for increasing horizontal reach in limited spaces, from 405 mm to over 12 m.

- Telescopic / Extendable / Adjustable 7th Axis: Best for adding height and vertical lift to your robot cell without the need for additional support structures, achieving a max height of 1700 mm through 870 mm of stroke.

- Custom / Tailored / Personalized Vertical 7th Axis: Best for handling material at various heights, available in lengths of 855 mm and 1530 mm.

Each configuration provides a unique value. No matter what configuration you choose, they are all robot-agnostic, so you can use the 7th axis with any of your preferred robot brands, including FANUC, Universal Robots, and others. With more robots, actuator types, and lengths to choose from, the Vention 7th axis is the most versatile and powerful robot actuator line on the market.

To support heavy-payload applications, including range extenders and overhead gantries, Vention is releasing a 7th axis for large cobots ecosystem. Combined with our recently announced XL extrusion ecosystem, these offerings will meet customers’ needs with fast delivery times, stronger structures and motion, and all the advantages of our hardware and software solutions.

To find the 7th axis that meets your specific needs, try out our Robot 7th Axis configurator tool.

Robot 7th Axis in real-life

Add a range extender to reduce the repetitive and manual tasks that are on your manufacturing floor. Some common applications include palletizing and packaging, painting, welding, machine tending, woodworking, and more.

Check out this video of a Vention Robot 7th Axis in-action from our partner, Woodworking Robotics:

Talk with an expert

Ready to take your factory floor to the next level of productivity and efficiency? Looking to embrace Industry 4.0 and smart manufacturing? Talk to our Vention experts to explore the possibilities of adding a 7th axis to your factory floor and stay ahead of the competition in today’s dynamic manufacturing world.