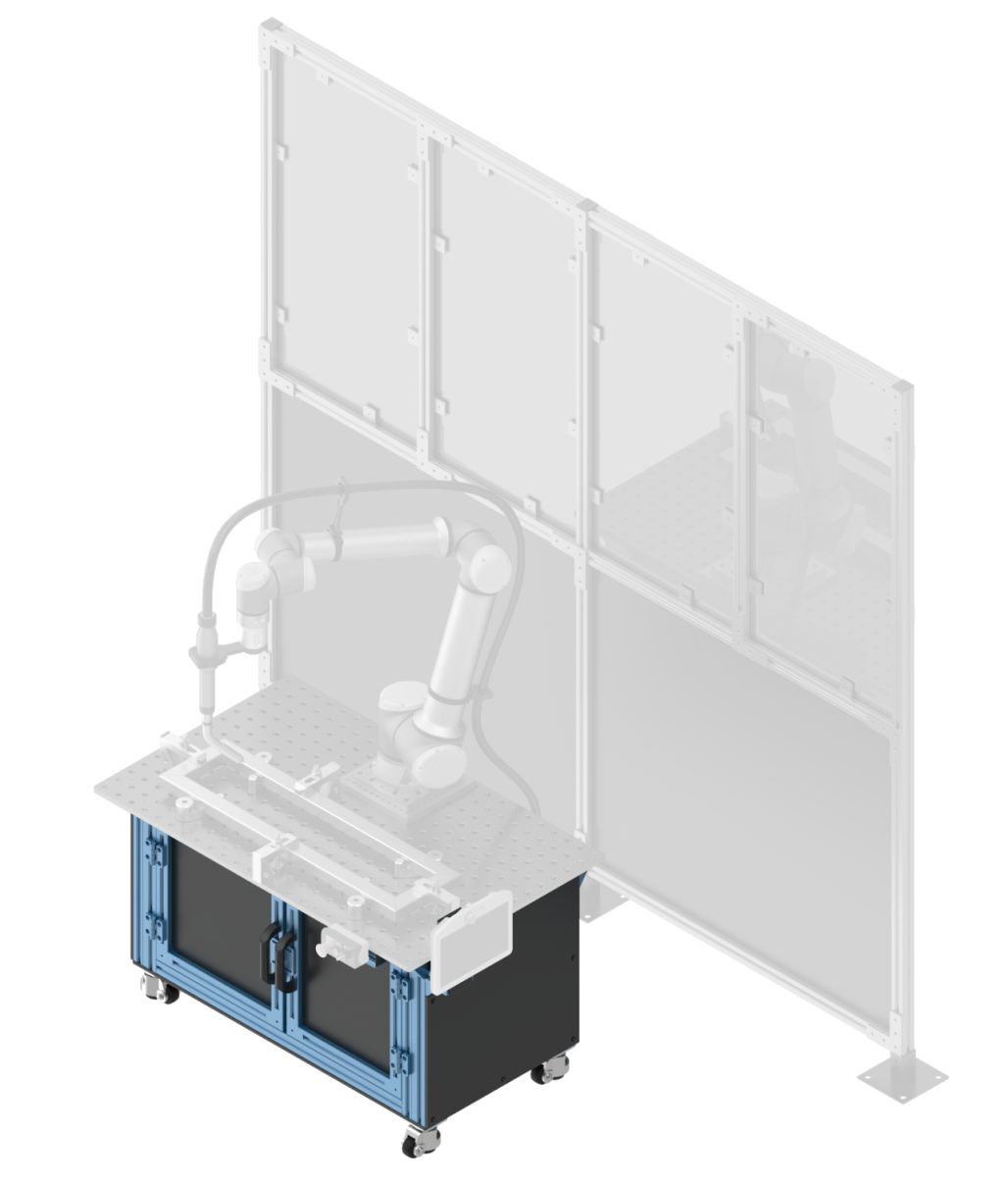

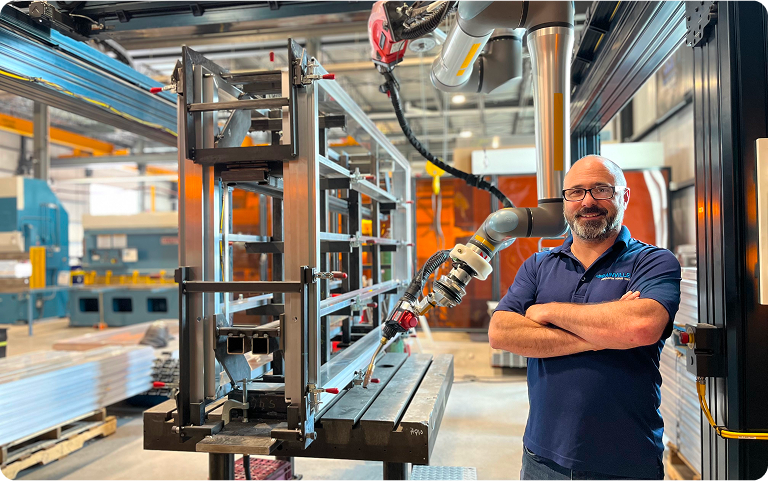

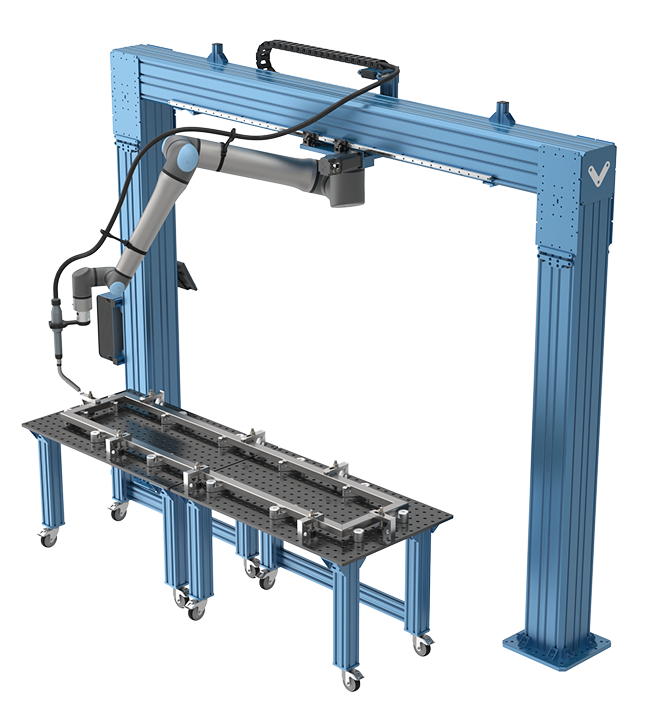

Customizable System

Build your welding cell based on your needs and space constraints, with the flexibility to choose components, robots, and software that you need to boost productivity.

Rapid Deployment

No more waiting for months to automate your welding operations. Design in minutes with real-time pricing, and get your robotic welding solution delivered in record time.

All-in-One Platform

Simplify your workflow with the support and convenience of integrated design, ordering, deployment, and operations tools. Eliminate risk with an ecosystem of 4,000+ plug-and-play parts.