Increasing production by 30% with cobot palletizing

Discover how Polykar implemented 2 cobot palletizers in each of their plants, resulting in increased productivity, predictability, and employee satisfaction.

Story Highlights

The project moved from initial discussions to kick-off within 2 weeks, demonstrating a rapid speed of execution.

Automating manual cobot palletizing led to a 30% increase in production.

2 cobot palletizers were deployed in the Edmonton facility, and the solution was later replicated in the Montreal facility.

Employee satisfaction and retention improved by shifting workers from manual tasks to high-value activities.

The Problem

Polykar is a leader in manufacturing sustainable packaging solutions, specializing in environmentally-friendly industrial garbage bags, compostable bags for organic waste collection, food packaging, and recycled polyethylene.

Their packaging process was highly labor-intensive and prone to human error, requiring employees to manually pick up bags at the end of the line, fill and tape boxes, apply labels, and stack them on pallets.

As demand for their products grew, Polykar recognized that the only way to scale their operations and boost productivity was through automation. This realization led them to seek a partner to implement industrial automation in both their Edmonton and Montreal plants.

"This project has had 3 major benefits: 1) employee satisfaction and retention, 2) improved productivity, which I would estimate to be at about 30% more output… and 3) the predictability of production."

The Project

Polykar chose to partner with Vention due to the continuity and support offered throughout the entire automation process. From the initial scoping to the final deployment in both their plants, Vention provided end-to-end service that ensured seamless integration of automated palletizing solutions.

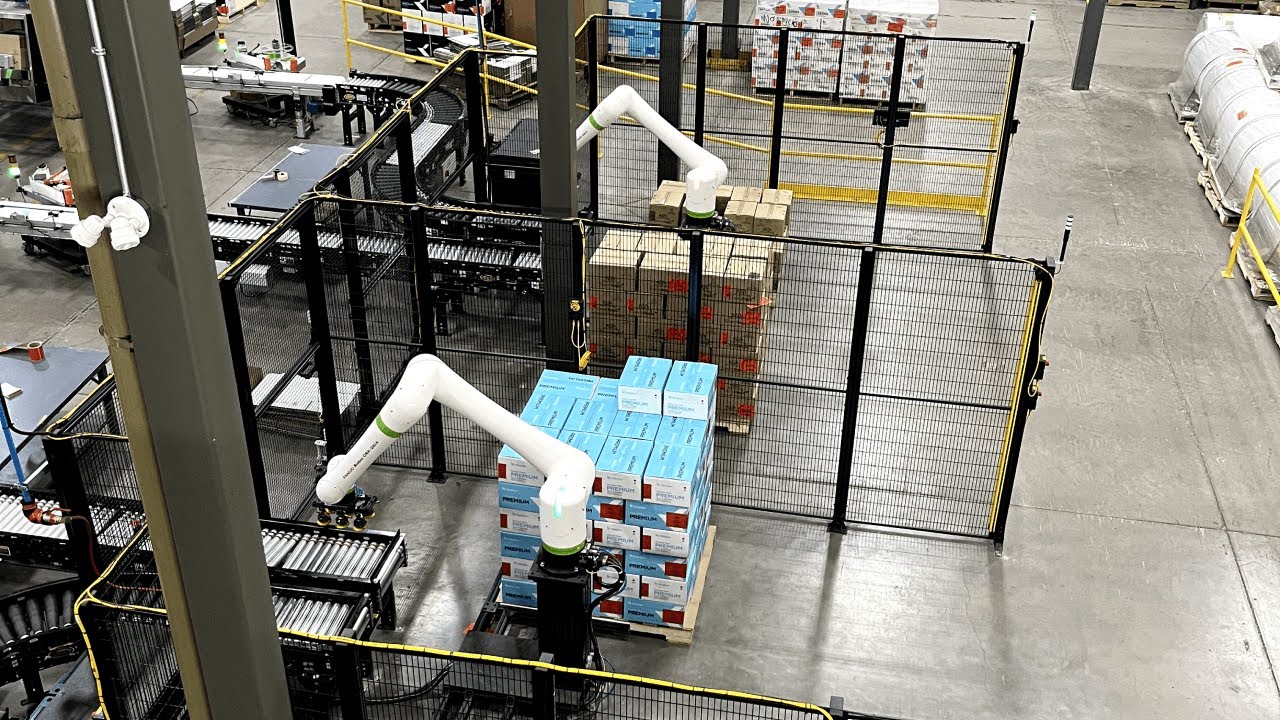

The partnership began at Polykar’s new Edmonton facility, where the company first tested automated palletizing. Two cobot palletizers were deployed, each with a dual infeed system and capable of handling different SKUs. This solution not only optimized their operations but also showcased the flexibility of Vention’s automation technology. After successfully testing and validating the system in Edmonton, Polykar replicated the solution at their Montreal facility.

The Vention team ensured a successful implementation by being present on-site for deployment and providing comprehensive training to both the operations managers and machine operators. The Palletizer MachineApp is so intuitive and easy to use, that anyone on the team can now create new robotic palletizing patterns in minutes.

By deploying these cobot palletizers, Polykar was able to reallocate its workforce from repetitive, labor-intensive tasks to more high-value activities, ultimately improving productivity and operational efficiency across both facilities.

The Results

With the introduction of cobot palletizers, Polykar experienced a 30% increase in production, marking a significant boost in operational efficiency. The transition to automation was well-received by the workforce, as it allowed employees to shift from repetitive, labor-intensive tasks to more value-added roles.

As a result, Polykar not only improved productivity but also saw an increase in employee satisfaction and retention—crucial outcomes in the face of the current labor shortages impacting the manufacturing industry. By freeing up staff for more rewarding tasks, the company strengthened its workforce and created a more stable, positive work environment.

In addition to workforce benefits, Polykar also achieved better predictability in its operations. Automation reduced health and safety risks, ensuring that production could continue running smoothly without the interruptions or hazards associated with manual processes. These improvements in reliability and safety further contributed to the overall success of the automation initiative.