A how-to guide for executives at small and medium manufacturing companies

High-volume manufacturing facilities, like those for cars and consumer electronics, have been automated for decades. However, the vast majority of manufacturing plants in North America—around 80%—are still operated by manual labour. And yet these manufacturers often face the same production cost pressures and labour shortages as their high-volume counterparts.

Industrial automation is often the best solution, though it can be daunting for many manufacturers. New adopters may find that deployment is costly, production delays are frequent, and it’s hard to balance safety with efficiency. Nevertheless, the need for automation continues to grow and manufacturers will not be able to avoid adoption for much longer.

We’ve put together the following how-to guide to help manufacturers transition into automation.

Step 1: Clarify your goals

Manufacturers often associate automation with labour cost savings, but the reality is that there are many reasons why companies automate. Are you automating to face labour shortage issues? Or are you looking to solve a process quality issue?

Here are the top four reasons to automate (from most to least quantifiable):

Realize cost savings on a manufactured product.

This usually means reducing labour costs. Value creation will come from the difference between the existing labour cost and the new cost of operating the automated equipment.

Improve product or process quality.

Savings here can be realized through defect and scrap reduction, or by reducing consumables during the manufacturing process. For example, if the process includes sealant, glue, or paint application, automation will ensure that just the right quantity is used every time.

Increase production throughput.

Usually, increasing throughput implies manufacturing more product by unit of time than with manual labour. Value creation will come from potential labour cost reduction (if any, see first reason above), but also, from the marginal profit extracted from incremental production. For the full value to be captured, one must assume that the market can absorb the extra supply of the manufactured product, without the price being eroded.

Reduced operating risk of injuries.

Contrary to the reasons already listed, the last consideration is harder to quantify but should nonetheless be taken seriously. Accidental risk of injuries or injuries induced by repetitive tasks do occur too often in manufacturing environments. Automation is a proven approach to reduce the occurrence of these risks.

Of course, every situation is unique. Before beginning any automation project, you must establish a clear objective. This will help govern your decision-making process, inform your payback requirements, and determine your budget.

Step 2: Choose the first project

With a clear goal in mind, you now face a new set of questions: Where should I begin? How? With whom?

Even Elon Musk admitted that 100% automation can be daunting, if not impossible. It is crucial to choose the right processes to automate in the right order.

Experts generally agree you should start small, with a low-risk project, and expand from there. Starting with a well-scoped project goes a long way when building your expertise, and increases your chance of success with future projects. With that in mind, make sure the ROI or payback is not the only thing you’re measuring; you want to factor in building long-lasting expertise as well.

The traditional approach to industrial automation was for manufacturers to carry out both technology and process feasibility testing. However, industrial automation use cases have now been productized—which means manufacturers can now adopt automation technology with fully vetted solutions. This decreases the risk associated with the “technology feasibility” of such an investment.

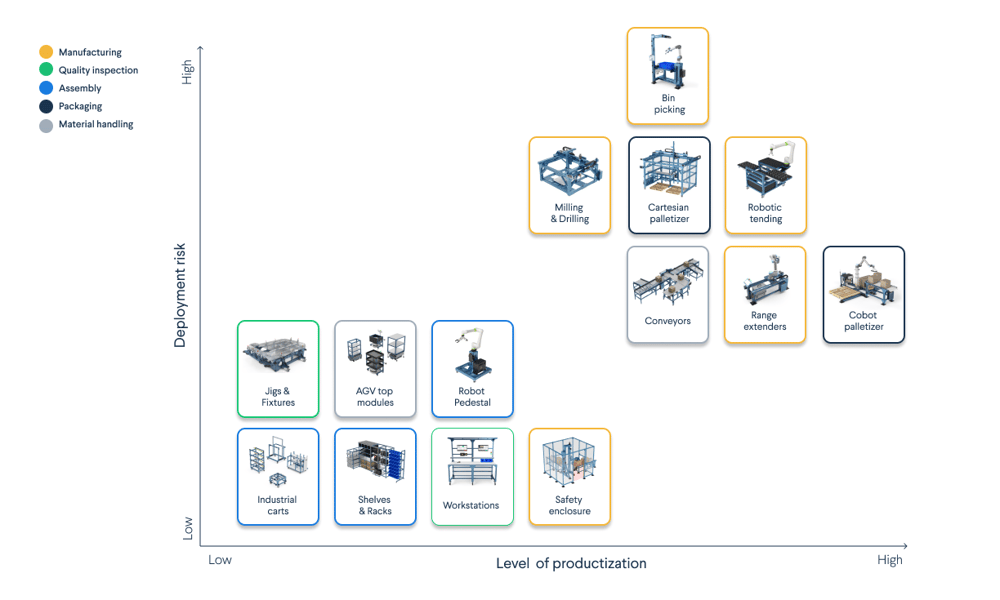

The matrix below lists commonly found “productized” industrial automation use-cases on the X-axis and their level of deployment risk on the Y-axis. It can act as a guide when trying to identify the best automation project for your company. A combination of well-productized applications and manageable deployment risk is usually a safe place to start your automation journey.

Step 3: Define your equipment requirements

If you’ve never bought industrial automation technology before, you’ll soon realize there are a number of “grey zones” between client and provider. Fuzzy requirement definitions; poorly communicated performance levels; early-stage technologies; upstream process variability… These all lead to project delays and extra costs that someone will have to absorb.

To prevent these grey zones from surfacing, your industrial automation project requirements should be well-defined across four areas of work:

Current and future process mapping

A process map distills a manufacturing procedure into distinct steps. When you create one, you understand the input conditions of manufactured goods supplied at each step, the specific tasks and subtasks conducted, and, of course, the cycle time required at each step.

Detailed mapping of the current manufacturing state helps define the future “automated process,” and in turn, determines which technology you’ll need.

Equipment (technical specifications and features)

There are several ways to design automated equipment for a given process. The more details that are provided in the scoping phase, the lower the chance of project “grey zones.”

Your list of equipment requirements should cover at least four areas:

- The equipment’s working environment.

- Hardware specifications.

- Electrical and software specifications.

- Safety and regulation compliance requirements.

Each of these areas can include an itemized list of specifications, as shown below.

Working environment |

Hardware specifications |

Electrical & software specifications |

Regulatory |

|---|---|---|---|

| Equipment maximum footprint | Equipment weight | HMI system | Safety system |

| Dust exposure | Equipment precision | PLC integration | Otherregulatory compliance |

| Humidity/liquid exposure | Frame rigidity | IoT/MES integration | |

| Operating temperature | In-feed specifications | Equipment software specifications | |

| Safety system | Other regulatory compliance |

Equipment acceptance tests

Service providers conduct equipment demos, or acceptance tests, to prove that all requirements have been met.

Two types of tests are usually considered:

- The “design” or “factory” acceptance test. Conducted at the provider’s site before equipment is shipped.

- The “field” or “site” acceptance test. Conducted at the client’s site, after the equipment has been installed and is ready for production.

Keep in mind that acceptance tests are sometimes tied to payment schedules—so you should define expectations for these tests carefully during the scoping phase.

Scope of services

The scope of services defines who’s responsible for different tasks during the automation project. Most providers will tailor their service offering based on the client’s pre-existing expertise, budget requirements, and machine-specific requests.

When considering a non-productized industrial automation solution, the cost of services can quickly rise to 30–50% of the overall project cost. By contrast, the cost of services for productized solutions is typically 0–15%.

Here are some examples of services:

Design & automate phase |

Deployment phase |

Operation phase |

|---|---|---|

| Custom software development | On-site installation | Operator training |

| User interface development | Design validation testing (or FAT) | Maintenance training |

| Field validation testing (or SAT) |

Vention MachineScope is a free tool that guides you through defining all the requirements for an industrial automation project. Learn more about MachineScope.

Step 4: Ensure attractive project economics

Once you have a list of requirements and proposals from your industrial automation provider, you can get a sense of your expected return on investment or payback period.

High-mix manufacturers, especially those operating without long-term supply agreements, typically seek to earn a payback in 9 to 18 months. In contrast, high-throughput manufacturers with long-term client contracts might accept payback periods of up to 3 or 4 years.

Use Vention’s ROI calculator to help determine the ROI and payback for your industrial automation project.

Conclusion

No matter how carefully selected, well-scoped, and potentially profitable your industrial automation project is, that can all be derailed if you work with a non-proven provider.

In all cases, it’s essential to work with a trusted partner who’s equipped to assist you before and after the project.