The availability of collaborative robots (cobots) and cloud-based machine design platforms are democratizing the robot space. Marked by an era of simplicity and shorter product life cycles, cobots are transforming formerly complex engineering projects into streamlined e-commerce experiences. Today, a robot cell can be designed and commissioned in as little as three days, versus 60+ days for similar projects using traditional programs.

So, how do you start taking advantage of cobots? Follow the four steps below to design and build a complete robot cell with Vention.

Step 1: Pick your Robot

Begin your robot cell design project by mapping the full sequence of tasks to be automated. Establish the target lead-time for each task. Then, group the tasks into “stations,” where a robot will be assigned. (Other, non-automated stations might involve human operators).

For each station identified, list the equipment you will need. Today, robots are widely used in industrial production, particularly in the machine tending, inspection, and handling sectors. You might require special equipment for part presentation, part positioning, or part removal. But before you think too hard about this equipment, you need to know what robot you’re working with. Keep the following criteria in mind when choosing one:

- Maximum payload. Weight the robotic arm can lift.

- Reach.Distance from the center of the robot to the fullest extension of the robotic arm

- Repeatability. Ability to pick something up at the exact same spot over numerous cycles.

- Support ecosystem. Availability of off-the-shelf accessories and expert support

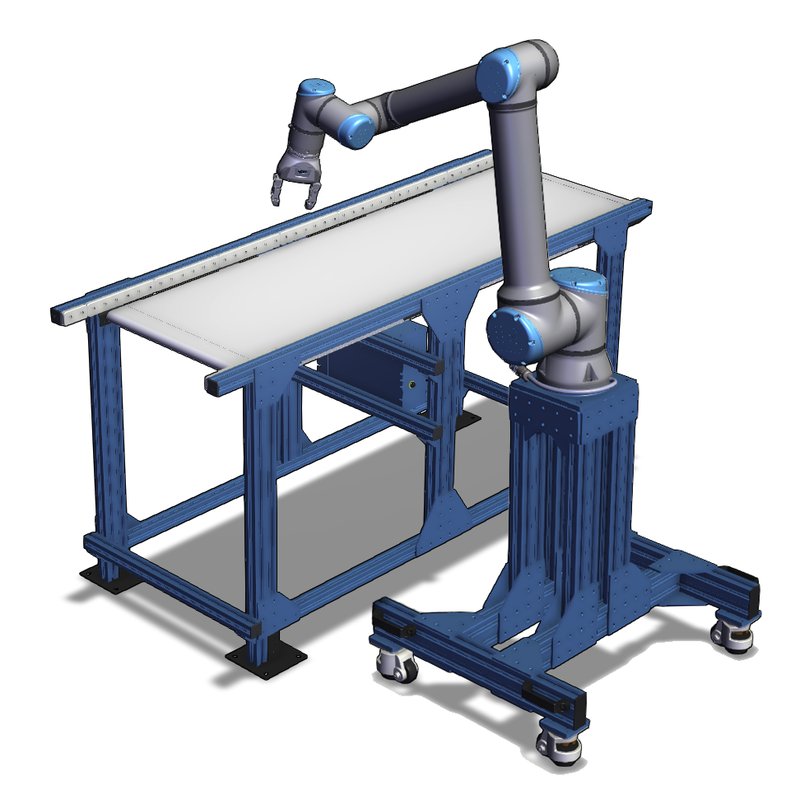

With over 600 modular parts—from grippers, fixtures, and tooling, to panels, safety enclosures, conveyors, and more—and a cloud-based 3D MachineBuilder platform, Vention has everything you need to build your complete robot cell. Our hardware components let you quickly deploy robotic arms for a huge variety of automation project, from simple pedestals and workstations to 7th-axis range extenders and palletizers. This gives you the flexibility to use the robot that best suits your industry and use case.

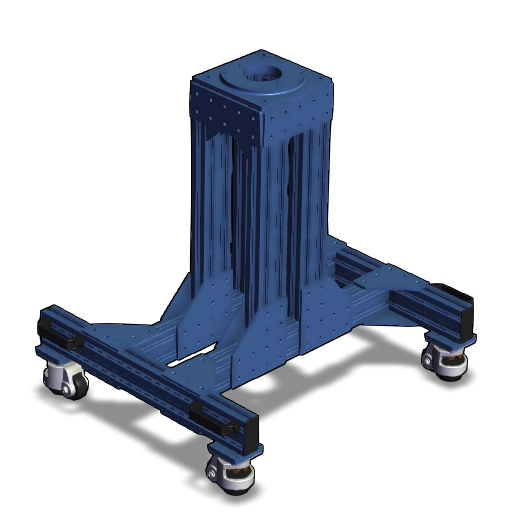

Step 2: Pick your Pedestal

Every robot station needs a pedestal. Pedestals can be fixed or mobile; that is, anchored to the floor or moving on wheels. As always, the ideal configuration depends on how the robot functions (including its payload, max reach, and any precision requirements).

When selecting a pedestal, three important factors to consider are whether it will be used for light or heavy-duty applications, the desired angle of the robotic arm, and whether its height should be fixed or telescopic.

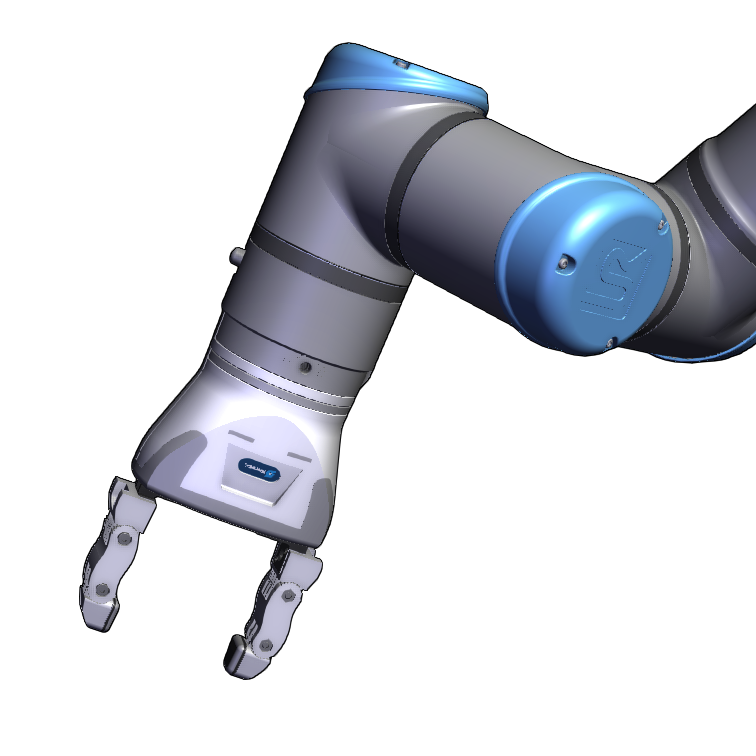

Step 3: Choose your Gripper

Robot grippers are the physical interface between the robot arm and the object. Since the gripper comes in direct contact with your product, a range of elements must be considered. Before googling best robot gripper, make sure you’re clear on what, exactly, will be the input and output of your robot cell. This includes noting the dimensions, weight, and materials of the objects to be handled.

From there, keep these six specifications in mind when choosing your gripper:

- 1) Cycle time. How fast do you need the gripper to clamp down or open?

- 2) Precision. Is a high degree of precision required?

- 3) Adaptability. Will the gripper handle objects of varying shapes and sizes?

- 4) Stroke. What are the part dimensions? (Bigger parts require bigger fingers.)

- Shape. Is the part flat like a piece of paper or solid like a brick?

- Payload. How much weight will the gripper have to carry?

Browse the parts library to see how Vention’s partner parts integrate with your equipment.

Step 4: Choose your material handling method

Material handling applications play a critical role in the success of almost any industrial automation project. One of the most popular material handling methods is conveyors, which can be used for pick-and-place applications, dispensing, assembling, and palletizing. Their level of complexity will vary from one design to the next.

Some of the most common conveyor types are roller conveyors and belt conveyors. Roller conveyors are best for heavy loads where less precision is required. They are used for simple movements, like moving boxes. Belt conveyors, on the other hand, are best for pick-and-place movements that require precisely locating smaller or irregularly shaped objects.

Vention conveyors, powered by Dorner, offer a fully customizable solution that serves a broad range of applications, and come ready to deploy with a kit including all required fasteners. And because they use only modular parts, Ventions conveyors let you scale as you grow. Browse Vention conveyors.

Today’s industrial robots cost a fraction of the price of their earlier counterparts. And new technology, like Vention’s cloud-based CAD program, is cheaper, more robust, and easier to program and maintain than ever before. Use cloud-based platforms to design all the custom equipment you need for the robot cell online, see the total cost and assembly time in real time, and order for next-day delivery, directly in the online 3D environment. You can even find “open-source” designs in Vention’s public library and customize them to fit your cell specifications. Get started on your first robot cell today.