In this day and age, agility and speed are some of the most important advantages any business can have. Engineering and manufacturing teams are seeking ways to design new products and ramp-up production faster than before, which is in line with rapidly changing customer demands.

But what if all the energy devoted to improving speed only affects certain industries? What if all those operational transformations and continuous improvement programs have little impact compared to the other forces at stake?

Vention 3D Machine Builder provides an amazing ecosystem to study “product design agility” in various organizations, as design variables (i.e., CAD software, part library, purchasing workflow, etc) are the same for all users. At the aggregate level, the Vention Manufacturing Automation Platform can be used to assess time taken to complete a design, number of design iterations required, and lead-time to purchase across a range of dimensions such as industry, designer expertise, and type of equipment designed.

Recently, we wondered what was driving the difference in workflow lead-time chosen by our users. Was it the design’s complexity? Was it the designer’s familiarity with the Vention 3D MachineBuilder? Or was it something else?

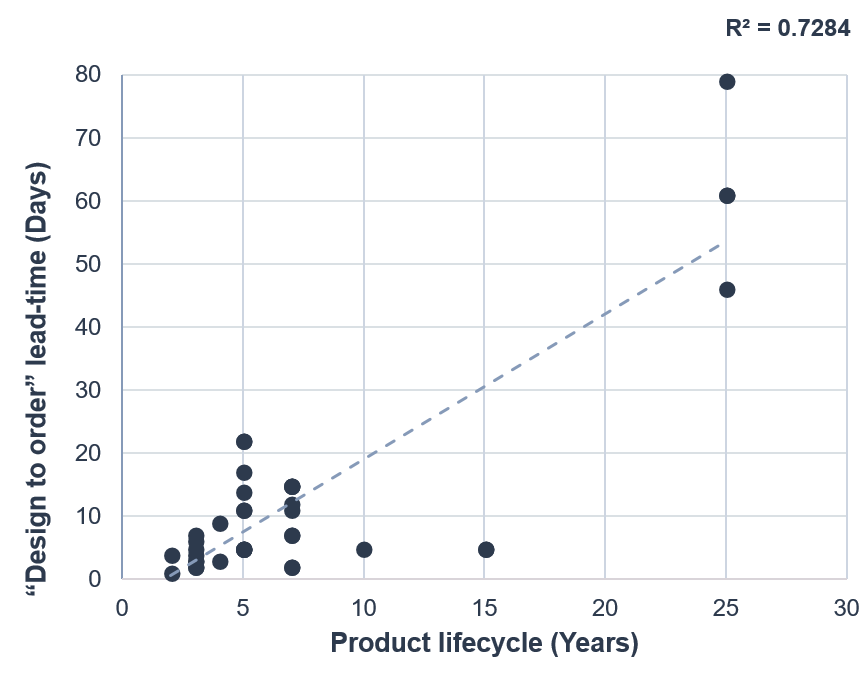

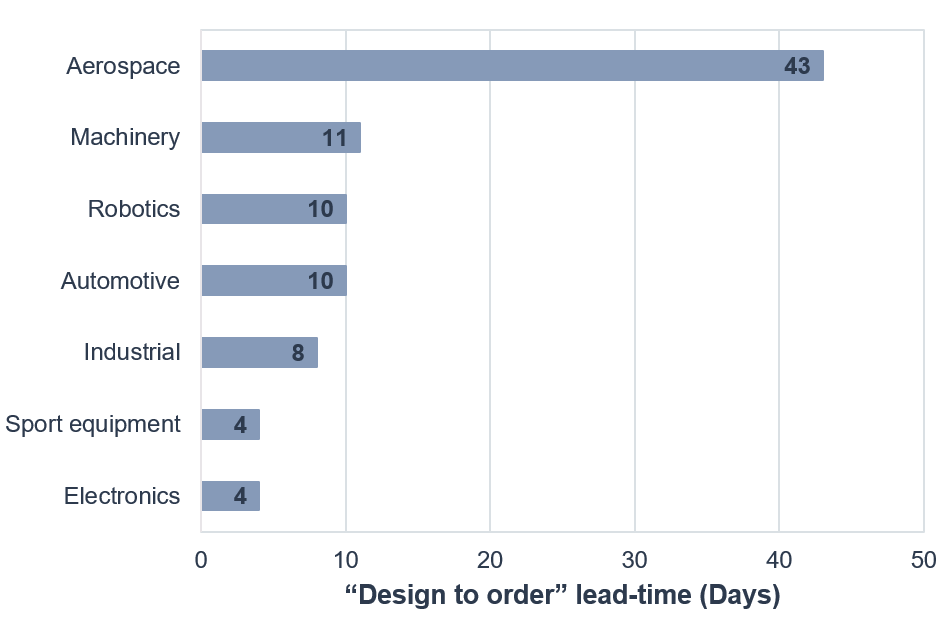

It turns out that the only variable impacting the speed at which users navigated the design-to-order workflow was their industry affiliation, and more specifically, the product lifecycle in their industry. Users operating in industrial electronics, for example, were able to design and order 10X faster than users in aerospace. And those results stayed the same even when correcting for product design complexity.

The pace at which products evolve dictates the sense of urgency experienced within organizations. Saving two months of development lead-time on a product with a two-year lifecycle has an enormous impact on the product’s ROI. Similarly, a two-month gain would have almost no impact on a 20+ years lifecycle product like an aircraft. This is an economic reality that organizations seem to embed in their unconscious behaviors, and conscious effort to improve development speed doesn’t seem to be enough to overcome this.