Industrial machines are often affected by vibration, which can loosen the threaded fasteners that hold joints together. To keep your machine’s joints tightly fitted together in such conditions, you need something that will prevent your fasteners from coming loose.

So what’s the best solution? After testing six ways to protect fasteners from vibration, we found Nordlock washers and Loctite products to be the most effective.

Keep reading to find out what products we tested, how we evaluated them, and how to find the right anti-vibration solution for you.

What we tested:

Washers, adhesives, and locking patches are some of the most common ways to keep fasteners tight. We tested six of these products in search of the best anti-vibration solution:

Washers

- Split washers

- Nordlock washers

Adhesives

- Loctite 248 with Loctite 7088 primer

- Loctite 2760

Nylon locking patches

- Nylock-treated T-nuts

- Zinc-plated fasteners with locking patches

Methodology:

To evaluate each solution, we conducted an accelerated vibration test. This means we subjected our test jig to vibrations with significantly higher frequency and amplitude than in standard operational environments. Any solution that performs well in our accelerated environment will be sure to meet the demands of real application scenarios!

Performance criteria

We want to make it easy for you to build the right products, so we put a lot of thought into which components we offer on our machine design platform. Fasteners are no exception. Here’s what we looked for with each solution:

- Rate at which the fasteners loosened

- Total number of loose fasteners (observed after the vibration test)

- How easy it was to use

- How well it integrated with Vention’s other components

Results:

Split washers

The split washer works in two ways: first, its spring shape helps maintain the fastener’s preload. Second, the sharp edge of the split washer digs into the parent material to prevent the fastener from unscrewing.

This second function only works when the parent material is softer than the split washer, which is made of spring steel. For this reason, split washers won’t be effective in any application that uses steel as the joint’s parent material. You don’t have to worry about this with Vention joints, though. Our joints are made of 6061-T6 aluminum alloy, which is softer than any split washer.

Split washer test results: Out of 66 fasteners, 4 came completely loose during the test, and an additional 22 fasteners were under spec post-test (but were not yet turning freely).

Split washer conclusions: Split washers are a good anti-vibration method for Vention joints. The washers are able to dig into the parent material, build up a burr, and resist further loosening.

Nordlock washers

The Nordlock washer is a two-piece wedge-style washer. Each half of the washer has two serrated surfaces: fine serrations on the outside, and larger wedge-shaped serrations on the inside. The fine serrations dig into the parent material when the fastener is torqued. This prevents the washers from slipping against the bolt or joint’s surface.

The broadly serrated inner surfaces prevent the fastener from unscrewing. Because of the wedges, any attempt to loosen the fastener will increase its preload before the washer is able to ratchet to the next set of wedges. Nordlock washers are an excellent choice of anti-vibration method.

Nordlock washer test results: Out of 20 fasteners, none came completely loose during the test, and 14 fasteners were under spec post-test. Fourteen might seem like a lot, but it’s somewhat of a false positive; we believe the slight decrease in torque was caused by the initial settling of the washers (the two parts of each washer fell into place better after the test began).

Nordlock washer conclusions: The only drawback to these washers is that if your application features a counterbore, the fastener heads will protrude from it. Other than that, Nordlock washers are an excellent choice of anti-vibration method with extremely high vibration endurance.

Loctite 248 adhesive (with Loctite 7088 primer)

Loctite, one of the most common anti-vibration methods, is an anaerobic adhesive that works by gluing the male and female threads together. It’s available in many different strengths, from light to permanent. Loctite 248 is a medium-strength adhesive that comes in a convenient stick format. The manufacturer recommends using it with the Loctite 7088 primer.

Loctite 248 adhesive + primer results (9-hour curing period): Out of 25 fasteners, 7 came loose during the test (although none were completely loose), and 6 were under spec post-test.

Loctite 248 adhesive + primer conclusions: Loctite 248 is better than nothing, but it’s not as good as the other methods we tested. Plus, cleaning the threads, applying the primer and glue, and waiting for it to dry was inconvenient.

Loctite 2760 adhesive

Loctite 2760 is a liquid anaerobic adhesive with a high locking strength. The adhesive cures in the threads between the fastener and T-nut to create a glued connection between them. Loctite 2760 cures fully in 24 hours without the use of an activator, but we prepared this test on a Friday and ran it on the following Monday night, which gave it a full 72 hours of cure time.

Overall, Loctite 2760 performed very well, with only 2 fasteners coming loose during the test and an additional 6 found under spec post-test. Loctite 2760 is the best product so far in terms of the total number of fasteners under spec (in our post-test observations).

Loctite 2760 adhesive (72-hour curing period): Out of 30 fasteners, 2 came loose during the test (although none were completely loose), and 6 were under spec post-test.

Loctite 2760 adhesive conclusions: Loctite 2760 had the best overall performance out of any method we tested. However, that might not be enough to justify the time it takes to clean the fasteners and apply it, given that Nordlock washers are almost as good and much more convenient.

Nylok-treated T-nuts

These specialty T-nuts are just standard Vention T-nuts with locking patches applied to the threads. We tested two types: some with half of the thread treated, and others with the full thread treatment.

Unfortunately, neither type performed well. The Nylok patch adds so much resistance when installing a fastener that the T-nut twists and misaligns with the extrusion T-slot. To fix the misalignment problem, we had to tighten and loosen the fastener while wiggling the T-nut into position.

There are two problems here. First, all this wiggling means you might wear out the Nylok patch before you can even run a test. Second, it’s way too easy to get the T-nut misaligned. If you don’t carefully check and fix these misalignments before starting your application, the vibrations will cause the T-nut to realign itself. When it finally pops into the correct location, the bolt will lose all pre-tensioning.

Nylok-treated T-nut test results: Out of 20 fasteners (10 half-treated and 10 full-treated), 14 came completely loose during the test, and all 20 were under spec post-test.

Nylok-treated T-nut conclusions: Overall, Nylok-treated T-nuts are a poor choice of anti-vibration method. With 100% of the sample fasteners under spec post-test, need we say more?

Zinc-plated fasteners

To measure the performance of zinc-plated fasteners, we had to conduct two tests: one of bare zinc-plated fasteners, and one with a locking patch on the zinc-plated fasteners. This allowed us to isolate the two variables (the first being the change in surface treatment from black-oxide to zinc, and the second being whether or not there was a locking patch).

Both types of zinc-plated fasteners performed extremely poorly in vibration testing. This is likely due to the reduction in friction coefficient caused by the zinc plating.

These locking patches behaved similarly to those used in the Nylok-treated T-nuts. They were likewise difficult to install, and the locking patch caused the T-nut to rotate. Even with a full locking patch, the zinc-plated fasteners failed to match the performance of the standard black oxide baseline. It should be noted that the plain black zinc test had to be stopped 5 minutes early because the jig became too loose to continue the test.

Bare zinc-plated fastener test results: Out of 31 fasteners, 18 came completely loose during the test, and 20 were under spec post-test.

Zinc-plated fastener with full locking patch test results: Out of 36 fasteners, 11 came completely loose during the test, and 25 were under spec post-test.

Zinc-plated fastener conclusions: Overall, zinc-plated fasteners are a poor choice of anti-vibration method—even with the locking patch, their performance was worse than the black oxide baseline.

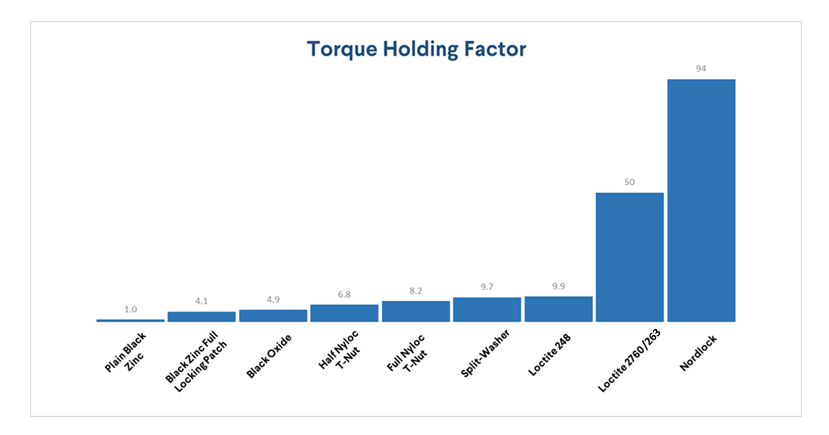

Performance comparison chart:

The chart shows the performance of each product tested relative to plain black zinc fasteners. The number above the bar represents the performance factor. For example, the standard black oxide fasteners used by Vention are 4.9 times better performing than plain black zinc. Likewise, Loctite 2760 or Nordlock could be used to achieve performance factors of 50 and 94 times better than plain black zinc for high vibration environments.

Recommendations:

We found that the most effective anti-vibration solutions are anaerobic adhesives and mechanical washers.

Overall, Nordlock washers were extremely effective. They’re as easy to install as any standard washer—and easier to install than the next-best contender, the Loctite 2760 adhesive. The drawback of Nordlock washers is that the fastener heads protrude above the part surface when installed in counterbores.

If you can’t use Nordlock washers—because your application includes counterbores, and fastener head protrusion is unacceptable—adhesives are a great alternative. Out of the two glues we tested, Loctite 2760 was the easiest to use (because it did not require any primer) and performed best. Just remember that fasteners used with Loctite 2760 must be free of contaminants.